In furniture manufacturing and woodworking industries, edge banding is an important decorative and protective material widely used for edge treatment of boards. Different types of edge banding materials have their own unique advantages and applicable scenarios, among which ABS edge banding and PVC edge banding are the two most common types. Although they can effectively protect the edges of wooden boards, prevent damage and improve aesthetics, they have significant differences in materials, performance, application range, installation methods, etc.

This article will discuss the differences between ABS edge banding and PVC edge banding in detail to help readers understand the advantages and disadvantages of the two and make a more appropriate choice.

ABS edge banding and PVC edge banding: What are they?

Before discussing the difference between the two, we must first understand the basic characteristics and definitions of ABS edge banding and PVC edge banding.

1. ABS edge banding: ABS edge banding is a plastic edge banding material made of acrylonitrile butadiene styrene (ABS). ABS is a high molecular polymer, which is widely used in furniture and woodworking industry due to its superior strength, impact resistance and good processing performance. ABS edge banding usually has high hardness, stability and heat resistance, and can be precisely processed and bonded on various surfaces.

2. PVC edge banding: PVC edge banding is made of polyvinyl chloride (PVC). PVC is a common plastic material with good corrosion resistance, insulation and water resistance. PVC edge banding is widely used in furniture, cabinets, floors and other fields, especially in terms of waterproof performance and anti-aging. The surface of PVC edge banding is smooth and can imitate wood grain, metal and other effects to meet different decoration needs.

ABS edge banding and PVC edge banding: What is the difference between them?

1. Material composition and physical properties

● ABS edge banding: ABS material has high rigidity and strong impact resistance, making ABS edge banding more durable and wear-resistant. It has high tensile and compressive strength, and can maintain a long service life during use. In addition, ABS edge banding has good high temperature resistance and can withstand temperatures up to 80°C without deformation or breakage.

● PVC edge banding: PVC material is softer and has better shaping ability, but its hardness and impact resistance are slightly worse than ABS. PVC edge banding has good water resistance and is suitable for humid environments, such as bathrooms, kitchens and other places. At the same time, PVC has strong elasticity, so PVC edge banding will be more suitable in some applications that require bending and flexibility.

2. Weather resistance and anti-aging ability

● ABS edge banding: ABS edge banding has good weather resistance, especially in terms of UV resistance and anti-aging. The color of ABS edge banding will not fade or turn yellow easily after long-term exposure to sunlight, which is suitable for products that require long-term stability.

● PVC edge banding: Although PVC edge banding can maintain a good appearance in the short term, its weather resistance and anti-aging performance are relatively weak due to the chemical properties of PVC itself. PVC edge banding may fade, age or even crack when exposed to strong light for a long time. Therefore, when used outdoors, PVC edge banding may not perform as stably as ABS edge banding.

3. Waterproof performance

● ABS edge banding: ABS edge banding has certain waterproof performance, but ABS is less water-resistant than PVC. Although it can resist the intrusion of water, ABS edge banding may be affected to a certain extent in a long-term humid environment.

● PVC edge banding: One of the biggest advantages of PVC material is its strong waterproof performance. PVC edge banding is almost immune to moisture and is suitable for high-humidity environments such as bathrooms and kitchens. Therefore, PVC edge banding is more common in applications with high waterproof requirements.

4. Processing performance and decorative properties

● ABS edge banding: ABS edge banding has very good processing performance and can be fixed to the edge of the sheet by hot pressing, gluing, etc., with excellent formability. Due to the high hardness of ABS, the edge banding effect is relatively strong and the edges are smooth and neat. The surface of ABS edge banding can be processed into various texture effects, such as wood grain, glossy, matte, etc., which has high decorative effect.

● PVC edge banding: PVC edge banding can also be installed by hot pressing or bonding. Its processing performance is slightly inferior to ABS edge banding, especially in occasions that require high hardness and wear resistance. The decorative effect of PVC edge banding is relatively poor. Although it can also present effects such as wood grain or stone grain, the texture and refinement are often not as good as ABS edge banding.

5. Price and economy

● ABS edge banding: Due to the high production process and performance requirements of ABS materials, the price of ABS edge banding is usually higher than that of PVC edge banding. ABS edge banding is suitable for the high-end market, especially in those furniture and decorations with high requirements, ABS edge banding is often required to ensure the quality and appearance of the product.

● PVC edge banding: Compared with ABS edge banding, PVC edge banding is cheaper and suitable for large-scale production and more economical applications. It is suitable for scenes with less demanding requirements, especially in cases with limited budgets, PVC edge banding provides a more economical choice.

Application fields of ABS edge banding and PVC edge banding

1. Application fields of ABS edge banding

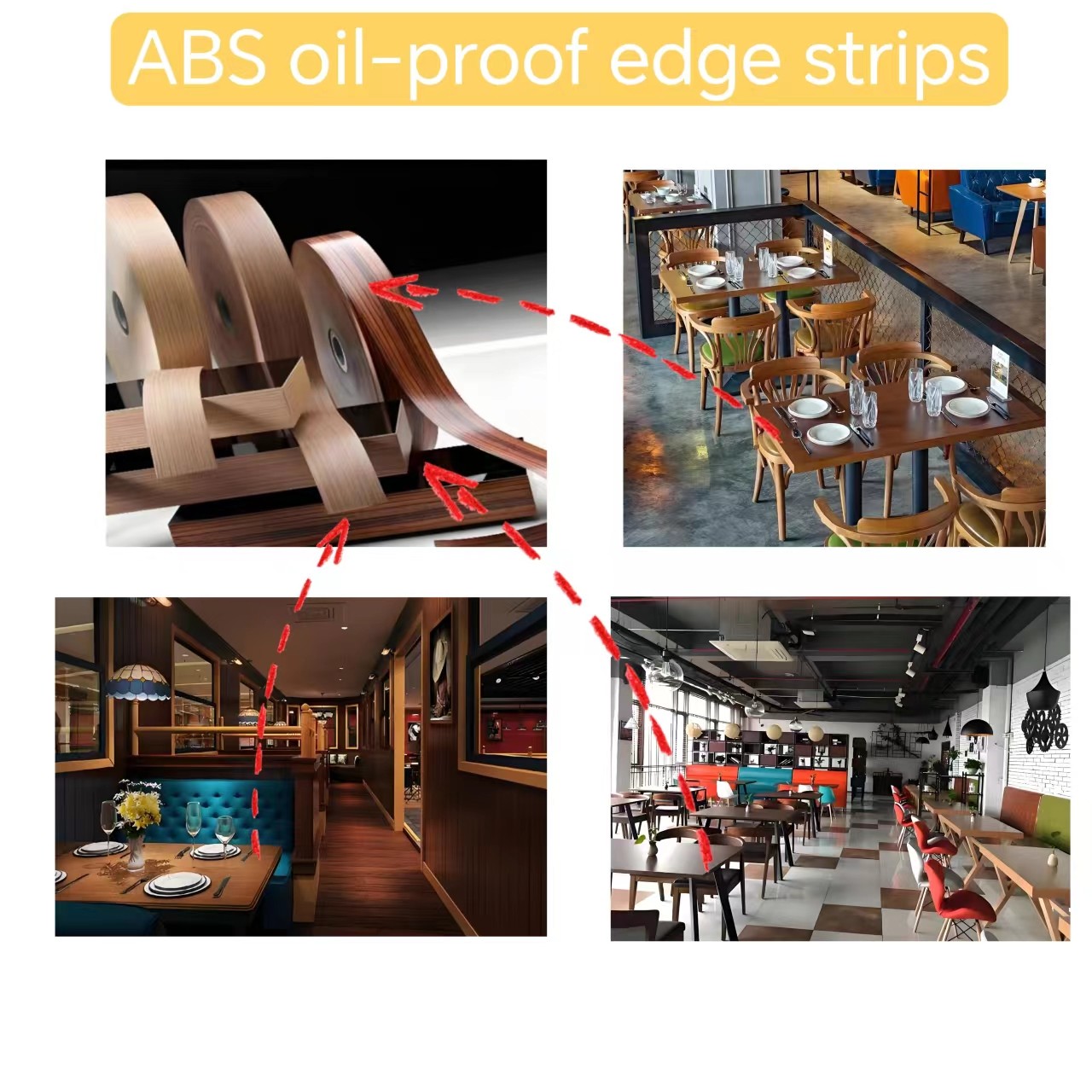

● High-end furniture: ABS edge banding is often used in high-end furniture and custom furniture due to its excellent decorativeness and durability. For example, modern wooden furniture, cabinets, tables and chairs, etc., often require ABS edge banding to ensure the exquisite and durable appearance.

● Kitchen and bathroom equipment: Although the waterproof performance of ABS edge banding is not as good as PVC, its high temperature resistance, UV resistance and impact resistance make it still widely used in kitchen and bathroom equipment.

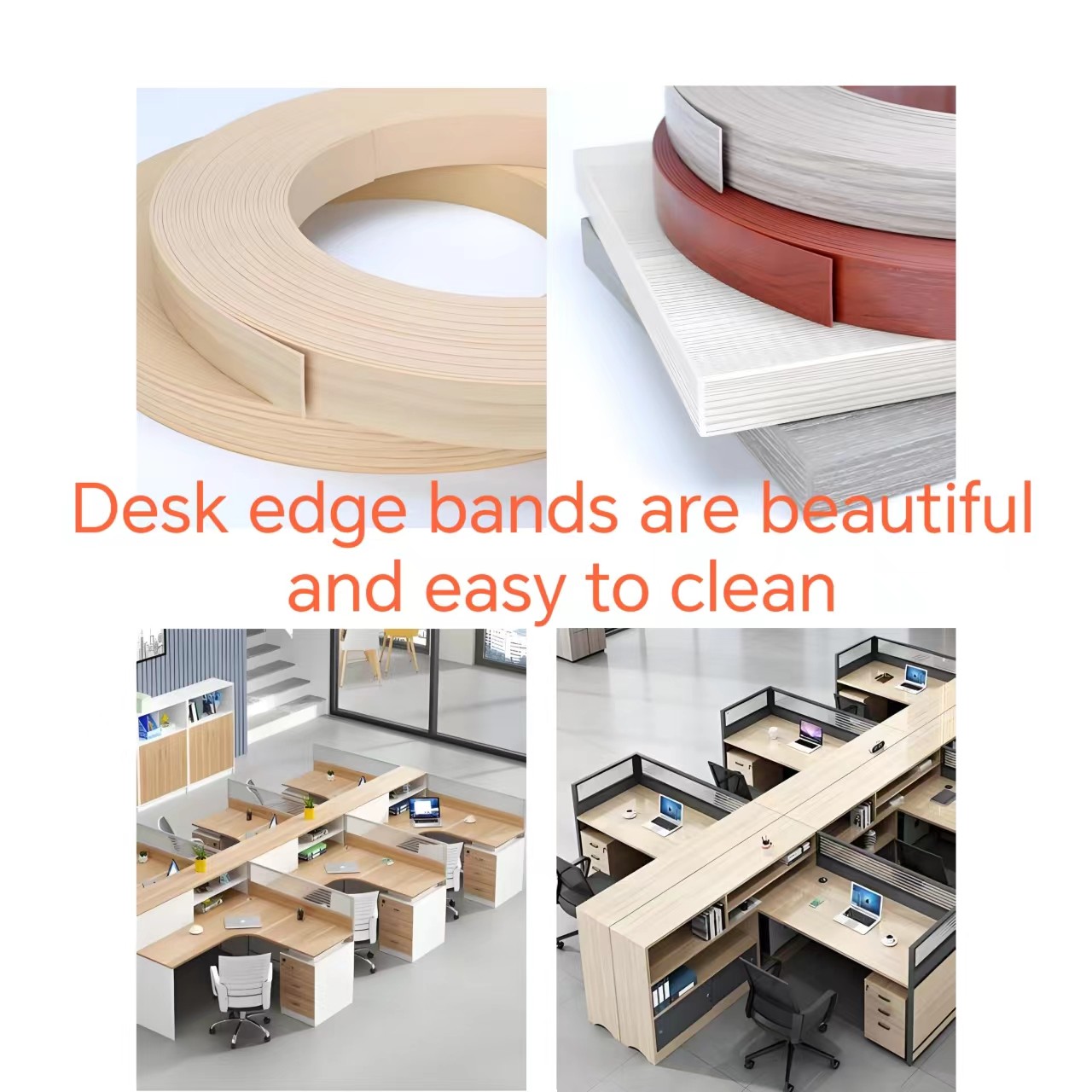

● Office furniture and commercial decoration: In the field of office furniture and commercial decoration, the high quality and exquisite appearance of ABS edge banding can enhance the overall design sense and meet the needs of modern offices and commercial spaces.

2. Application fields of PVC edge banding

● Economic furniture: PVC edge banding is mostly used in the production of economic furniture, especially in large-scale production scenarios. Due to its relatively low price, PVC edge banding is suitable for furniture with low requirements, such as standard kitchen furniture, economic cabinets, etc.

● Wet environment applications: The waterproof performance of PVC edge banding makes it an ideal choice for wet environments such as bathrooms and kitchens. Whether in home decoration or commercial decoration, PVC edge banding can provide long-lasting waterproof protection for products.

● Low-cost projects: In some projects with limited budgets, PVC edge banding is a cost-effective choice, especially for low-cost furniture produced in large quantities.

How to choose the right edge banding?

Whether to choose ABS edge banding or PVC edge banding needs to be decided according to the actual application scenario. If the product requires high durability, decorativeness and UV resistance, then ABS edge banding is undoubtedly a more suitable choice. If the demand focuses on waterproofness and cost control, especially in a humid environment, PVC edge banding will be a more ideal choice.

Dongguan Tingjie Decoration Materials Co., Ltd. – Bulk Edge Banding Supplier

Dongguan Tingjie Decoration Materials Co., Ltd. is a trusted manufacturer specializing in high-quality ABS edge banding and PVC edge banding. Our product line also includes wood grain edge banding, hot melt glue, and T-type and U-type profiles, ideal for a variety of applications. As a factory-direct supplier in China, we offer low prices on large orders and the flexibility to customize products to meet your specific needs. We supply customers across the globe with top-notch edge banding solutions, and our sales team is available to provide quotes and discuss pricing options tailored to your requirements.