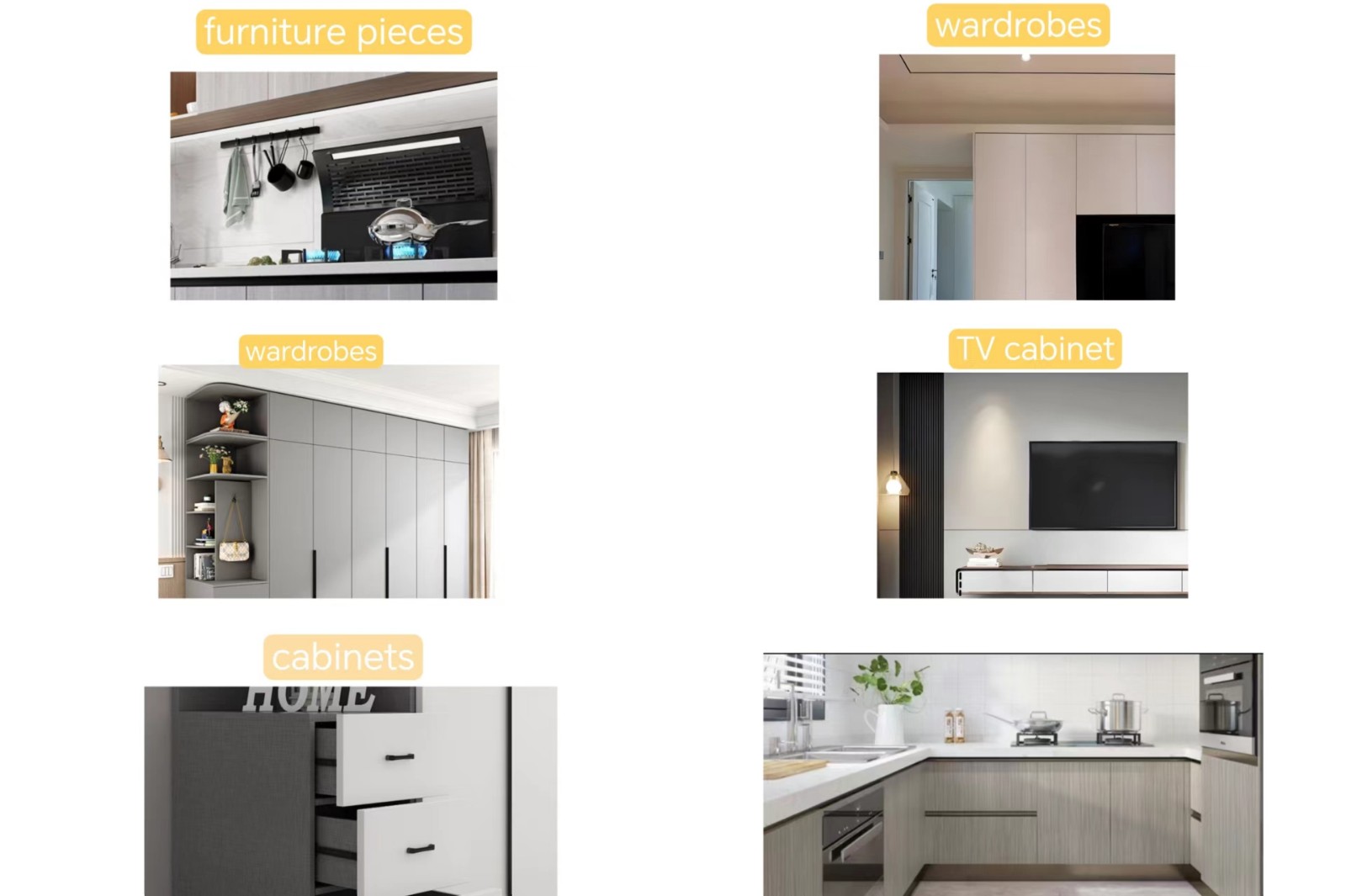

Edge banding is widely used in furniture manufacturing, woodworking, decoration and other fields, especially in the production of wardrobes, desks, cabinets, drawers and other furniture. The bonding of edge banding tape can not only improve the appearance, but also improve the durability and service life of furniture. Bonding edge banding tape is one of the key processes to ensure the high quality and durability of these furniture products.

So, in practical applications, can we use glue to stick edge banding tape? What are the characteristics of different glues? What types of edge banding are suitable for? This article will discuss the question "Can you glue edge banding?" in detail, analyze different types of glue and their applicable scenarios, and answer this question.

What is edge banding?

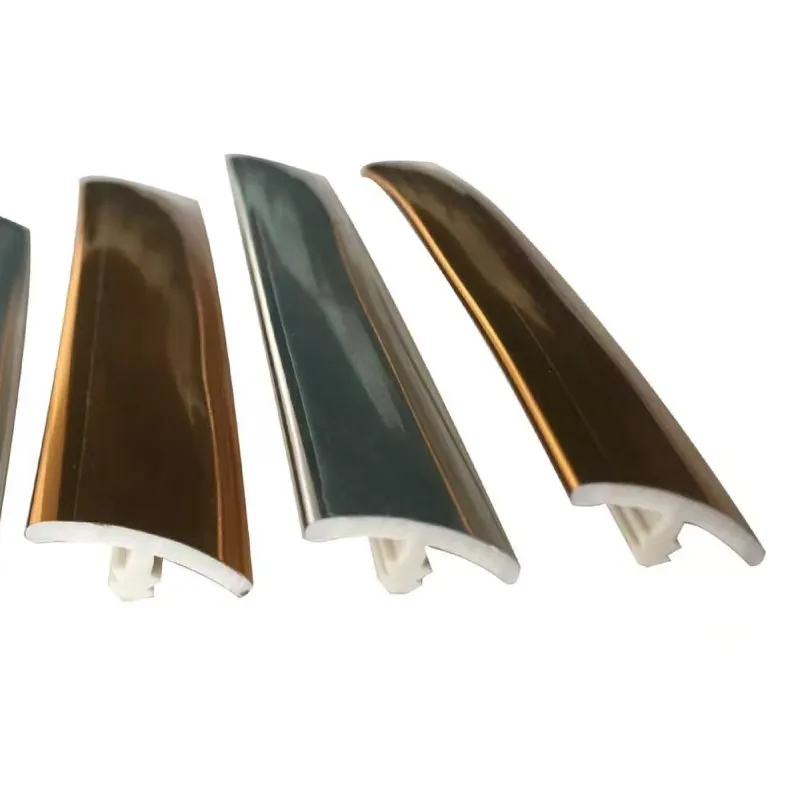

Edge banding is a strip material used to seal the edges of materials such as wood, particleboard, density board, melamine board, etc. Its main function is beauty, protection and increase service life. In woodworking or furniture manufacturing, the sealing of the edges can not only prevent moisture intrusion and improve the wear resistance of the board, but also make the appearance of the entire furniture more refined. Usually, there are many choices for edge banding materials, including Wooden edge banding, PVC edge banding, ABS edge banding, melamine edge banding tape, aluminum alloy edge banding tape, etc. Glue plays a very important role as the bonding material of edge banding.

What is the role of edge banding?

Edge banding not only has the effect of aesthetics, but also plays a protective role in preventing the internal fibers of the board from being exposed, and preventing moisture, dust, chemicals, etc. from eroding the board. After a period of use, the unsealed edge is prone to absorb water and swell, damaging the board structure, so the bonding of edge banding tape is very important.

What are the common materials for edge banding tape?

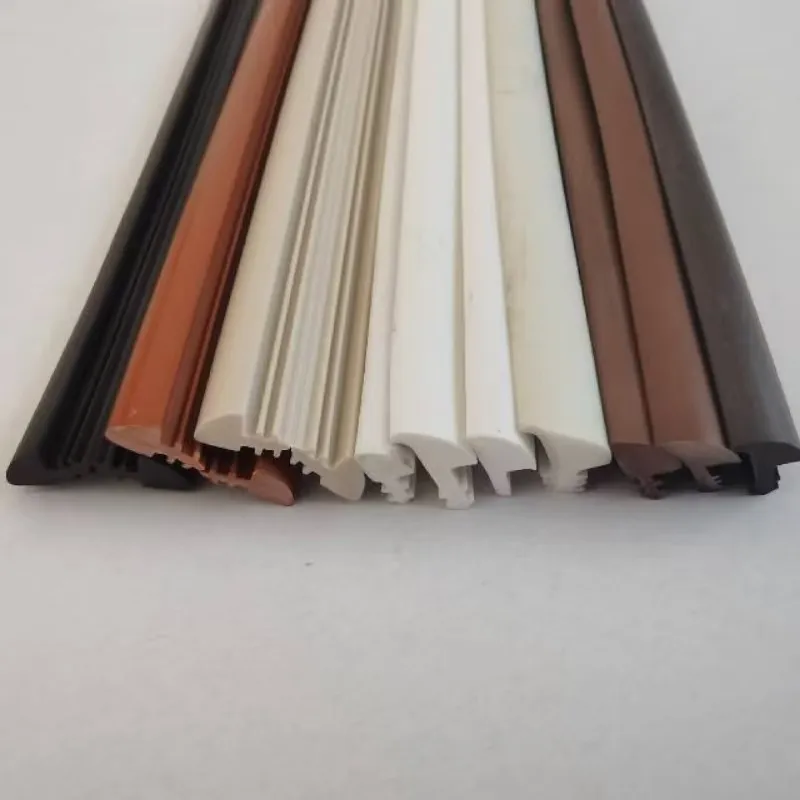

There are many kinds of edge banding materials, and edge banding tape of different materials needs to be bonded with different glues. Common edge banding materials include:

● Wooden edge banding: usually wood or particle board, which is used after grinding and painting.

● PVC edge banding: Made of polyvinyl chloride, it has good water resistance and chemical corrosion resistance.

● ABS edge banding: Made of polypropylene or acrylic materials, it has strong wear resistance.

● Melamine edge banding: Made of melamine paper and resin, it is resistant to high temperatures and is commonly used in furniture, kitchens and bathroom environments.

Different types of edge banding tape require different bonding methods and glues.

What is the role of glue in edge banding bonding?

Glue plays a vital role in the bonding of edge banding tape. It not only determines the strength of the bond, but also determines the stability of the edge banding tape during use. The choice of glue should not only consider the properties of the edge banding material, but also the usage scenario and required durability. Therefore, understanding the type, performance characteristics and applicability of glue is the key to successfully bonding edge banding tape.

What are the common types of edge banding glue?

At present, the glue commonly used for edge banding tape includes hot melt glue, solvent-based glue and water-based glue. Different types of glue are suitable for different edge banding and application scenarios.

● Hot melt adhesive: Hot melt adhesive is a type of glue that melts after heating and solidifies after cooling. Hot melt adhesive is widely used in the bonding of edge banding, especially in furniture production lines. Common types of hot melt adhesives include EVA (ethylene vinyl acetate) hot melt adhesive and PUR (polyurethane) hot melt adhesive.

● Solvent-based glue: This type of glue is a liquid at room temperature and solidifies by the volatilization of the solvent. Solvent-based glue is usually used for bonding PVC edge banding tape and metal and plastic materials.

● Water-based glue: Water-based glue mainly uses water as a solvent and is suitable for some applications with high environmental requirements, especially for moisture-sensitive materials.

What are the advantages of hot melt adhesive?

Hot melt adhesive is widely used in the bonding of edge banding tape, and its advantages are mainly reflected in the following aspects:

Fast curing

After the hot melt adhesive is heated and melted, it is applied to the surface of the edge banding tape and the substrate, and can be solidified after a short cooling. The bonding speed is fast and suitable for large-scale production. For the furniture industry, the fast curing time greatly improves production efficiency.

Strong bonding force

Hot melt adhesive can provide strong bonding effect, especially EVA and PUR hot melt adhesive, whose strength and durability make it a common glue in furniture manufacturing.

Environmentally friendly and solvent-free

Hot melt adhesive does not contain solvents, so it has less impact on the environment and does not release harmful gases, which meets modern environmental protection requirements.

Strong adaptability

Hot melt adhesive can be used on a variety of edge banding materials, including PVC, wood, ABS, etc., and is suitable for bonding in different environments.

What is the difference between EVA and PUR hot melt adhesive?

In actual production, EVA and PUR hot melt adhesives are the two most commonly used hot melt adhesives. Although they are both hot melt adhesives, there are some differences in their applications.

● EVA hot melt adhesive: EVA (ethylene vinyl acetate) hot melt adhesive is a kind of glue that can be quickly solidified after being melted by heating. It is widely used in the bonding of PVC edge banding, melamine edge banding tape, Wooden edge banding tape, etc. EVA hot melt adhesive has strong bonding force and low cost, and is suitable for most common edge banding materials.

● PUR hot melt adhesive: PUR (polyurethane) hot melt adhesive has higher temperature resistance and chemical resistance than EVA hot melt adhesive, and is particularly suitable for some high-demand environments, such as the automotive industry and home appliance industry. PUR hot melt adhesive is often used for bonding high-end edge banding strips, which can provide stronger adhesion and durability, especially suitable for edge banding strips made of materials such as ABS and melamine.

How to choose glue for edge banding tape?

Choosing a suitable glue not only requires considering the material type of the edge banding strip, but also making a decision based on the actual application environment. Different edge banding strips of different materials and usage scenarios require different types of glue.

The influence of edge banding materials on glue selection

Different edge banding materials require different bonding properties. Taking common PVC, ABS, and Wooden edge banding tape as examples, their surface properties, water absorption, and temperature resistance are different, which determines the choice of glue:

● PVC edge banding: The surface of PVC material is smooth and it is not easy to react strongly with glue. Therefore, when choosing glue, special attention should be paid to the adhesion of the glue. Commonly used glues include EVA hot melt glue and solvent-based glue. EVA hot melt glue is suitable for most PVC edge bandings, while solvent-based glue is suitable for PVC edge bandings with higher bonding strength requirements.

● ABS edge banding: ABS materials have strong wear resistance and impact resistance. PUR hot melt glue is often used for bonding ABS edge bandings due to its excellent chemical resistance and bonding strength. PUR glue not only provides strong bonding force, but also adapts to the strong physical properties of ABS edge bandings.

● Wooden edge banding: The bonding of Wooden edge banding tape needs to consider the water absorption of wood and its affinity with glue. EVA hot melt glue is suitable for most Wooden edge bandings, and can provide sufficient bonding force and faster curing speed.

The impact of environmental factors on glue selection

Edge banding is often used in indoor environments, but for some special scenarios that require moisture resistance and high temperature resistance, environmental factors must also be considered when choosing glue. For example, in humid environments such as kitchens and bathrooms, EVA hot melt adhesive and solvent-based adhesive may lose some of their bonding strength due to long-term moisture, while PUR hot melt adhesive is more suitable for these special environments.

Precautions during edge banding bonding

The bonding process of edge banding tape seems simple, but there are many details to pay attention to during the actual operation. The correct bonding method can ensure that the edge banding is firmly adhered to the surface of the board and avoid bonding failure due to improper glue quality, improper construction, etc.

Treatment of the substrate surface

Before bonding the edge banding tape, it is very important to ensure that the substrate surface is clean and flat. Any dust, oil, and moisture may affect the adhesion of the glue to the substrate. Therefore, before using the glue, it is best to clean the substrate surface with a detergent or alcohol to ensure that the surface is dry and free of impurities.

Glue coating

When applying glue, ensure that the glue is evenly covered on the contact surface between the edge banding tape and the substrate. Too much glue will result in a thick bonding layer, affecting the appearance, while too little glue will result in a weak bond. Avoid bubbles or voids during application and ensure that the glue is evenly distributed in the bonding area.

Curing Time and Temperature Control

When using hot melt adhesive, the control of curing time and temperature is crucial. Too long or too short a curing time may affect the effect of the glue. The temperature and curing time need to be adjusted according to the type of glue and production requirements to ensure the bonding quality of the edge banding tape.

Why Do International Buyers Choose Tingjie as Their Wholesale Edge Banding Supplier?

Tingjie has earned a reputation as a reliable supplier of edge banding products, delivering top-quality ABS and PVC edge banding at competitive prices. Our China-based factory ensures a steady supply for international buyers in Europe, North America, the Middle East, and Vietnam. We offer customized manufacturing, allowing customers to choose from various colors, textures, and thicknesses.