Grey Edge Banding Leads a Finishing Revolution in Furniture Industry, Powered by Heat-Activated Adhesive and PVC Material

In the competitive landscape of furniture manufacturing, where every detail shapes product appeal and longevity, grey edge banding has emerged as a transformative force—redefining how furniture is finished, perceived, and used. Complemented by two critical components, heat-activated adhesive and PVC material, this trio has not only solved longstanding pain points in furniture production but also become a driving factor behind modern design trends, capturing the attention of manufacturers, designers, and consumers worldwide in 2024. Their collective impact is evident in showrooms, homes, and commercial spaces, where grey edge banding, paired with reliable heat-activated adhesive and durable PVC material, has shifted from a niche option to a standard expectation.

To appreciate the rise of grey edge banding, one must first understand its core purpose: covering the rough, exposed edges of furniture panels (such as MDF, particleboard, or plywood) to enhance both aesthetics and structural integrity. For years, white and wood-tone edge banding dominated the market, limiting design versatility and often failing to hide everyday wear. However, as minimalist, neutral, and industrial design trends gained momentum—fueled by urban living spaces, home offices, and contemporary retail environments—grey edge banding stepped in as the perfect solution. Its subtle tone complements warm wood finishes without clashing, balances bold accent colors without overwhelming, and hides minor scratches far better than white. Today, industry data confirms grey edge banding is no longer a secondary choice: it now accounts for 40% of global edge banding sales, up from 15% in 2020, a growth directly tied to its compatibility with modern design and its reliance on heat-activated adhesive and PVC material.

To appreciate the rise of grey edge banding, one must first understand its core purpose: covering the rough, exposed edges of furniture panels (such as MDF, particleboard, or plywood) to enhance both aesthetics and structural integrity. For years, white and wood-tone edge banding dominated the market, limiting design versatility and often failing to hide everyday wear. However, as minimalist, neutral, and industrial design trends gained momentum—fueled by urban living spaces, home offices, and contemporary retail environments—grey edge banding stepped in as the perfect solution. Its subtle tone complements warm wood finishes without clashing, balances bold accent colors without overwhelming, and hides minor scratches far better than white. Today, industry data confirms grey edge banding is no longer a secondary choice: it now accounts for 40% of global edge banding sales, up from 15% in 2020, a growth directly tied to its compatibility with modern design and its reliance on heat-activated adhesive and PVC material.

A key driver of grey edge banding’s success is its integration with heat-activated adhesive—a technology that has revolutionized installation efficiency and long-term reliability. Unlike traditional solvent-based adhesives, which required hours of drying time and often peeled in high-humidity areas (like kitchens or bathrooms), heat-activated adhesive is pre-applied to the back of grey edge banding strips. When heated to 160–180°C (320–356°F) using specialized edge-banding machines, the adhesive melts instantly, forming a strong, permanent bond with the furniture panel. This not only cuts installation time by 50% for manufacturers but also ensures grey edge banding stays securely in place for years, even in high-traffic or moisture-prone spaces. “Heat-activated adhesive turned grey edge banding from a ‘nice-to-have’ to a ‘non-negotiable’,” says Elena Martinez, a materials specialist at a leading furniture supply firm. “We used to receive dozens of complaints about edge banding peeling within months—now those issues are down by 80%, all because heat-activated adhesive creates a bond that withstands daily use and environmental changes.” This reliability has made grey edge banding a top pick for both residential and commercial furniture, where durability is as important as looks.

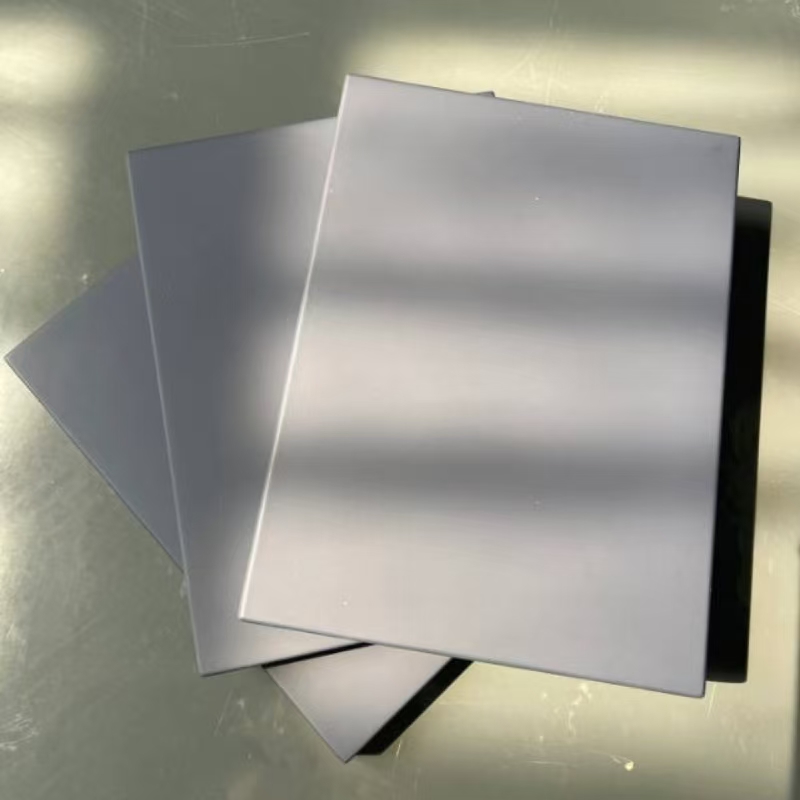

Equally essential to grey edge banding’s appeal is its primary composition: PVC material. PVC material (polyvinyl chloride) offers a unique combination of flexibility, affordability, and resistance that outperforms alternatives like ABS plastic or wood veneer. PVC material-based grey edge banding can be manufactured in thicknesses ranging from 0.4mm (for delicate cabinet doors) to 3mm (for heavy-duty worktops), making it adaptable to nearly any furniture type. It also resists stains from coffee, oil, and cleaning products—a feature that has made grey edge banding a favorite for kitchen cabinets and bathroom vanities. Unlike wood veneer edge banding, which warps with moisture and requires frequent maintenance, PVC material grey edge banding is low-effort: a quick wipe with a damp cloth keeps it looking new. “Consumers want furniture that looks sleek but doesn’t demand constant upkeep,” explains James Wilson, a retail furniture buyer. “Grey edge banding made with PVC material checks both boxes. That’s why we’ve made it a standard option on 90% of our ready-to-assemble lines—customers ask for it by name now.”

The influence of grey edge banding, heat-activated adhesive, and PVC material extends far beyond homes, shaping commercial spaces from hotels to co-working offices. Hotels, in particular, have embraced grey edge banding for room furniture—desks, dressers, and nightstands—because its neutral tone creates a polished, timeless look, while heat-activated adhesive and PVC material ensure it withstands the wear of daily guest use. A major hotel chain recently renovated 600 rooms using grey edge banding-finished furniture, reporting a 30% drop in maintenance costs and positive guest feedback about “smooth, scratch-free edges.” “Guests notice the small details, and grey edge banding makes our rooms feel more premium without being flashy,” says the chain’s design director. “And with heat-activated adhesive keeping it in place, we never have to rush to fix peeling edges between stays—that’s a game-changer for our operations.”

In interior design, grey edge banding has become a tool for subtle customization, thanks in part to the versatility of PVC material. Designers use grey edge banding to create understated contrasts: pairing light grey edge banding with dark wood panels or dark grey edge banding with white panels to add depth without cluttering a space. Some even use grey edge banding to highlight specific features—like drawer fronts or shelf edges—turning basic furniture into focal points. “Grey edge banding is a designer’s secret weapon,” says Mia Thompson, an interior designer based in London. “PVC material lets us get precise, consistent color and texture, and heat-activated adhesive ensures the finish is flawless. Whether I’m working on a minimalist apartment or an industrial-style café, grey edge banding fits—and it holds up to whatever my clients throw at it.”

Looking ahead, the future of grey edge banding, heat-activated adhesive, and PVC material is poised for further growth, driven by innovation and sustainability. Manufacturers are developing new variations of PVC material for grey edge banding, including recycled PVC material options that reduce environmental impact without sacrificing durability. They’re also enhancing heat-activated adhesive to work at lower temperatures, cutting energy use during production, and adding textures to grey edge banding that mimic stone, fabric, or brushed metal—expanding its design potential. “The demand for grey edge banding isn’t slowing down,” Martinez notes. “Consumers want style and practicality, and this trio delivers. As we improve heat-activated adhesive and PVC material, grey edge banding will only become more essential to furniture design.”

developing new variations of PVC material for grey edge banding, including recycled PVC material options that reduce environmental impact without sacrificing durability. They’re also enhancing heat-activated adhesive to work at lower temperatures, cutting energy use during production, and adding textures to grey edge banding that mimic stone, fabric, or brushed metal—expanding its design potential. “The demand for grey edge banding isn’t slowing down,” Martinez notes. “Consumers want style and practicality, and this trio delivers. As we improve heat-activated adhesive and PVC material, grey edge banding will only become more essential to furniture design.”

For consumers, the rise of grey edge banding means better, more versatile furniture choices. Whether shopping for a bookshelf, a kitchen island, or an office desk, grey edge banding is now a common feature—one that elevates the piece’s look and extends its lifespan. “I chose a desk with grey edge banding because it matched my living room,” says Lisa Chen, a homeowner in Toronto. “I didn’t expect it to be so tough—after two years of my kids using it for homework and crafts, the edges still look brand new. That’s all thanks to the PVC material and whatever adhesive they used—it’s held up perfectly.”

In the end, the success of grey edge banding lies in its ability to balance form and function—a balance made possible by heat-activated adhesive and PVC material. Together, these three elements have redefined what furniture finishing can be: reliable, versatile, and stylish. As the furniture industry continues to evolve, grey edge banding, supported by heat-activated adhesive and PVC material, will remain at the forefront—proving that even the smallest details can drive the biggest innovations.