The Rise of EVA Hot Melt Adhesive, Industrial Hot Melt Adhesive, and Hot Glue Adhesive in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency, reliability, and versatility are critical factors in choosing the right bonding solutions. Among the most widely used options are EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive. These adhesives have revolutionized assembly lines across industries, offering fast bonding, easy application, and consistent results.

In today’s fast-paced manufacturing environment, efficiency, reliability, and versatility are critical factors in choosing the right bonding solutions. Among the most widely used options are EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive. These adhesives have revolutionized assembly lines across industries, offering fast bonding, easy application, and consistent results.

The Versatility of EVA Hot Melt Adhesive

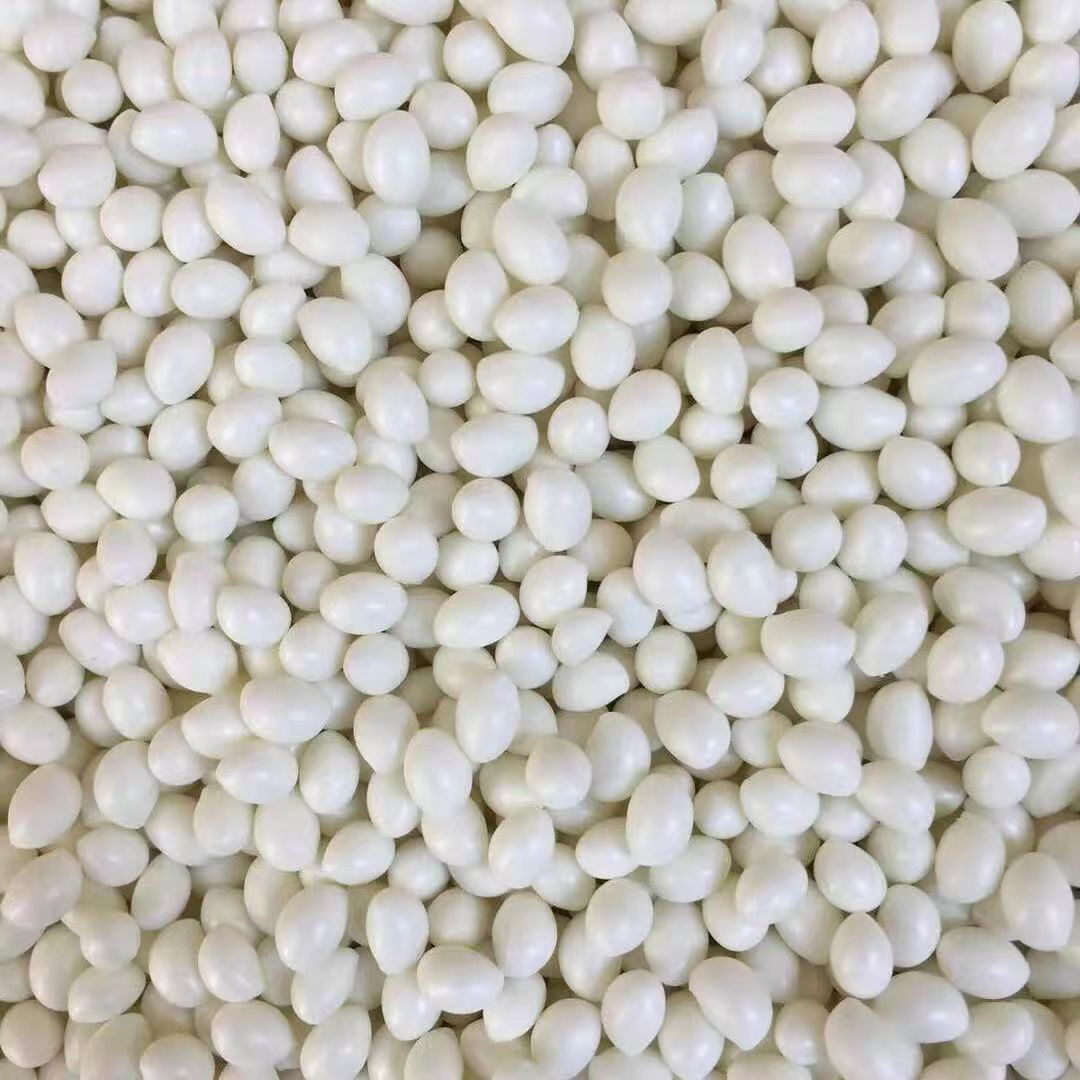

EVA hot melt adhesive has become a staple in packaging, woodworking, bookbinding, and nonwoven industries. Known for its excellent adhesion to a variety of substrates, EVA hot melt adhesive provides a strong bond that sets quickly, reducing production time. Its low melting point makes EVA hot melt adhesive easy to handle, while its flexibility ensures durability even in changing temperature conditions.

Manufacturers appreciate that EVA hot melt adhesive is solvent-free and environmentally friendly compared to traditional bonding agents. This characteristic has contributed to the growing popularity of EVA hot melt adhesive in sustainable manufacturing practices.

The Power of Industrial Hot Melt Adhesive

When it comes to heavy-duty applications, industrial hot melt adhesive is the go-to choice. This high-performance variant is designed to withstand extreme temperatures, heavy loads, and harsh environmental conditions. Industrial hot melt adhesive is widely used in automotive assembly, electronics manufacturing, and construction, where reliability is paramount.

The fast curing time of industrial hot melt adhesive allows for high-speed production without compromising bond strength. Its ability to adhere to both porous and non-porous materials makes industrial hot melt adhesive a versatile solution for complex industrial applications.

The Convenience of Hot Glue Adhesive

For both industrial and craft applications, hot glue adhesive offers unmatched convenience. Available in sticks compatible with handheld glue guns, hot glue adhesive allows for precise application and quick bonding. This makes hot glue adhesive ideal for packaging, product assembly, and even DIY projects.

The accessibility of hot glue adhesive has made it a favorite among small businesses and hobbyists. Its strong bond and fast setup time mean projects can be completed more efficiently, whether in a factory or at home.

Technological Advancements in Adhesive Solutions

Recent innovations have further improved the performance of EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive. Manufacturers are developing formulations with enhanced heat resistance, improved flexibility, and better adhesion to difficult substrates.

For example, new EVA hot melt adhesive formulas offer superior bonding to recycled materials, supporting the circular economy. Advanced industrial hot melt adhesive products can withstand temperatures exceeding 200°C, making them suitable for high-heat applications. Meanwhile, improved hot glue adhesive sticks provide longer shelf life and more consistent melting.

Environmental Considerations

As sustainability becomes a priority for manufacturers worldwide, the eco-friendly nature of EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive is gaining recognition. These adhesives are typically solvent-free, producing fewer volatile organic compounds (VOCs) than traditional alternatives.

Furthermore, the solid form of EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive means there is less waste compared to liquid adhesives. Many formulations are also recyclable, aligning with the growing demand for sustainable production practices.

Market Growth and Future Trends

The global market for EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive is experiencing steady growth. Factors driving this expansion include the rise in e-commerce packaging, the growth of the furniture industry, and the increasing adoption of automated assembly lines.

Industry experts predict that demand for high-performance industrial hot melt adhesive will grow particularly rapidly in the automotive and electronics sectors. Meanwhile, the popularity of EVA hot melt adhesive is expected to rise in the packaging industry due to its versatility and eco-friendly properties. The consumer market for hot glue adhesive continues to expand, fueled by the growth of DIY culture and small-scale manufacturing.

Choosing the Right Adhesive for Your Application

Selecting the appropriate adhesive depends on several factors, including the materials being bonded, the production environment, and performance requirements. EVA hot melt adhesive is an excellent all-purpose choice for many industries, offering a balance of performance and cost-effectiveness.

For applications requiring maximum durability and heat resistance, industrial hot melt adhesive is the preferred option. Its ability to maintain a strong bond under extreme conditions makes it invaluable in demanding industrial settings.

When speed and convenience are paramount, hot glue adhesive provides an ideal solution. Its ease of use and quick bonding make it perfect for both small-scale operations and large manufacturing facilities.

As manufacturing processes continue to evolve, the importance of reliable bonding solutions cannot be overstated. EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive have proven themselves as versatile, efficient, and sustainable options for modern production needs.

With ongoing technological advancements and a growing emphasis on sustainability, these adhesives are poised to play an even more significant role in the manufacturing industry. Whether for packaging, furniture production, automotive assembly, or creative projects, EVA hot melt adhesive, industrial hot melt adhesive, and hot glue adhesive offer the performance and reliability that modern manufacturers demand.