PVC sealing strips and PVC waterproof sealing strips are a common sealing material and are widely used in many fields such as construction, decoration, automobiles, electronics, etc. Its main function is to seal doors, windows, pipes, joints and other locations to prevent water, dust, sound insulation, heat preservation, etc. However, how to correctly install PVC sealing strips is the key to ensuring its use effect and extending its service life.

This article will discuss in detail the correct installation method, common problems and solutions of PVC sealing strips to help consumers and engineering technicians better master installation skills.

What is the role of PVC sealing strips?

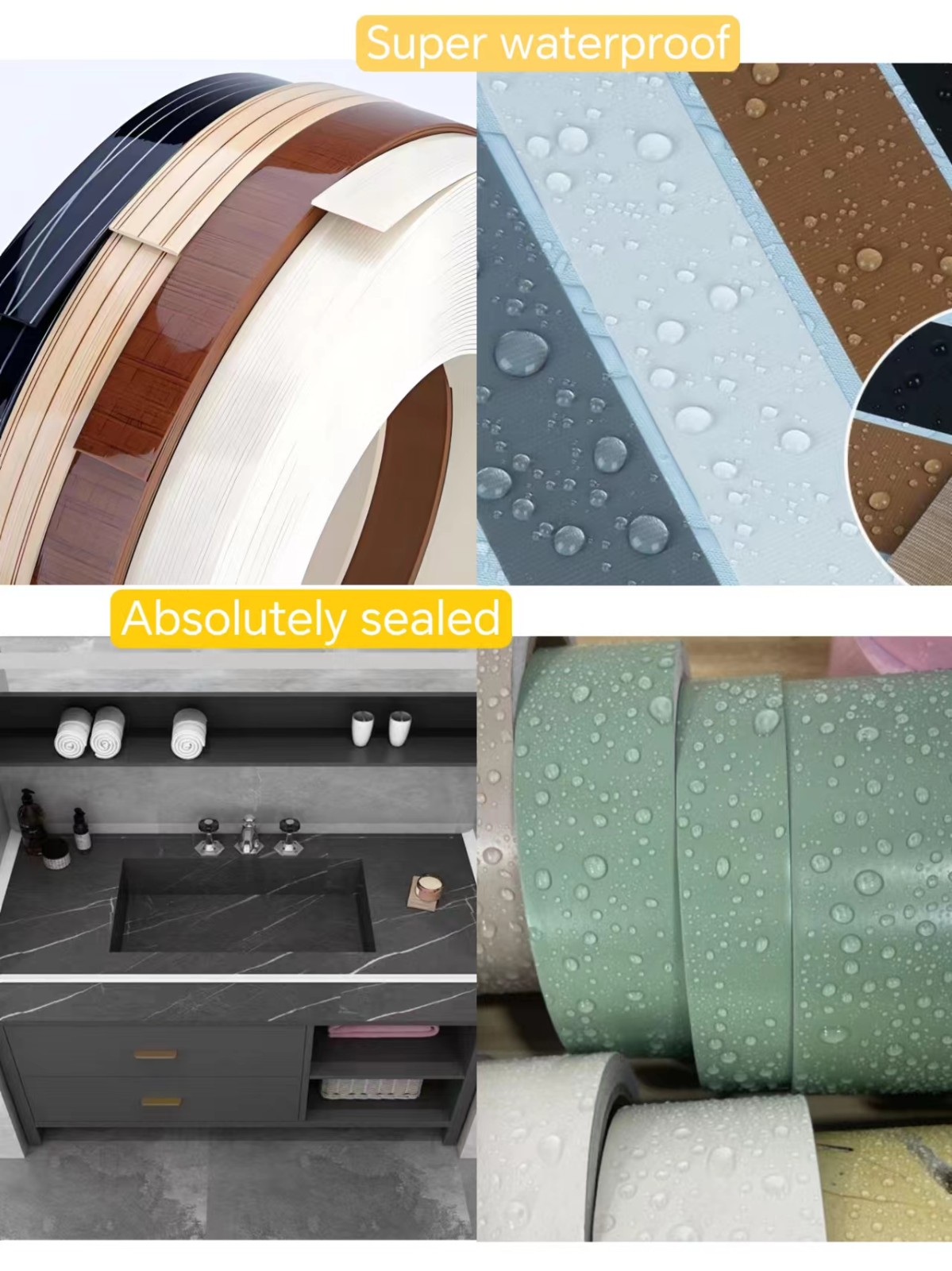

PVC sealing strips are a sealing product made of polyvinyl chloride (PVC). According to different needs, PVC sealing strips can be divided into ordinary sealing strips and PVC waterproof sealing strips. They are usually used in doors, windows, automobiles, pipes, home appliances, ships and other fields to prevent the penetration of air, water, dust, and noise, and have heat insulation, sound insulation, shock absorption and other effects.

1. Waterproof performance: PVC waterproof sealing strips are particularly suitable for areas that require waterproofing, such as bathrooms, kitchens, sinks, window frames, etc., and can effectively prevent moisture penetration.

2. Sound insulation effect: PVC waterproof sealing strips can fill gaps and reduce the spread of noise. They are widely used in the sealing of windows and door frames to reduce the interference of external noise.

3. Heat insulation: PVC waterproof sealing strips have a certain heat insulation effect on temperature changes, and are particularly suitable for doors and windows and other parts that are easily affected by cold and heat.

4. Dust and windproof: In home and industrial environments, PVCsealing strips can prevent the entry of dust and wind to ensure fresh indoor air.

What are the preparations before installing PVC sealing strips?

Correctly installing PVC sealing strips can not only effectively improve the sealing effect, but also extend its service life. Therefore, before installation, sufficient preparations must be made.

1. Choose the right PVC sealing strips

There are many types of PVC sealing strips on the market, including different materials, sizes, shapes, etc. When choosing, you must choose according to the specific application requirements. For example, for the sealing of door and window frames, choose soft PVC sealing strips; while for places that need to withstand greater pressure and long-term use, choose PVC waterproof sealing strips with moderate thickness.

2. Clean the installation surface

Before installing PVC waterproof sealing strips, you must ensure that the installation surface is clean, dry and flat. If there are impurities such as dust, oil, rust, etc. on the surface, it will affect the adhesion of the strips, resulting in poor sealing effect or strips falling off. You can use detergent and wet cloth to thoroughly clean the surface and wipe it dry with a dry cloth.

3. Measure and cut the strips

Before installing PVC sealing strips, you need to accurately measure the area to be sealed. According to the measurement results, appropriately cut the length of the PVC sealing strips to avoid gaps or excessive strips after installation. When cutting, it is best to use sharp scissors or special cutting tools to ensure neat cuts.

4. Prepare tools and auxiliary materials

When installing PVC sealing strips, some auxiliary tools such as scissors, knives, tape, cleaning cloth, ruler, etc. are usually required. For some sealing positions that are difficult to fix, you can also prepare some strong glue or double-sided tape to enhance adhesion.

What are the correct installation steps for PVC sealing strips?

When installing PVC sealing strips, following the correct steps is the key to ensuring the effect. The following are the standard steps for installing PVC sealing strips:

1. Determine the installation location

2. Cut the strips

3. Remove the protective film or adhesive paper

4. Paste the PVC sealing strips

5. Strengthen fixation

6. Check the sealing effect

1. Determine the installation location: First, you need to determine the installation location of the PVC sealing strips. For door and window sealing strips, the size of the gap in the door and window frames should be confirmed; for PVC waterproof sealing strips, the waterproof requirements of bathrooms, kitchens and other areas should be confirmed. Select the installation location of the PVC waterproof sealing strips according to the actual situation and mark it clearly.

2. Cut the strips: Cut the PVC sealing strips of appropriate length according to the size of the installation location. If a longer sealing strip needs to be fixed, an appropriate margin should be left for adjustment. Try to keep the cut of the strip flat when cutting to avoid irregular cutting that causes poor sealing.

3. Remove the protective film or adhesive paper: PVC sealing strips are usually self-adhesive, that is, there is a protective film or adhesive paper on the back. When installing, the protective film or adhesive paper should be removed first. This step requires careful operation to avoid the strip from adhering to the wrong place.

4. Paste the PVC sealing strip: Align the PVC sealing strip with the marked position and carefully paste the strip to the surface. When installing, press the strip gently to make it in close contact with the surface. If there are air bubbles or the strip is uneven, you can use a scraper to gently flatten it to ensure the sealing effect.

For longer installation areas, it is recommended to install in sections, paste a certain length of PVC sealing strip each time, and then gradually press it to the entire area. This can avoid installation difficulties caused by too long or too short strips.

5. Strengthen fixation: For some special locations or places that require stronger sealing, auxiliary glue or double-sided tape can be used to further strengthen the fixation of the PVC sealing strip. Especially at the corners of the window frame, the adhesive force of the strip may be weak, and proper fixing measures can prevent the strip from falling off.

6. Check the sealing effect: After the installation is completed, the sealing effect of the PVC sealing strip should be checked. You can touch the gap with your hand to check whether there is an obvious gap. If a problem is found, the installation position of the strip should be adjusted in time to ensure that the strip fits tightly.

Common problems and solutions in the installation of PVC sealing strips

Although the steps for installing PVC waterproof sealing strips seem simple, some problems are often encountered during the actual operation. The following are common installation problems and solutions:

1. The strip is not firmly adhered

If the PVC sealing strip is not firmly adhered after installation, it is usually caused by incomplete surface cleaning or excessive environmental humidity. The solution is to re-clean the surface and ensure that the surface is dry before installation. For places where adhesion needs to be enhanced, you can choose to use strong glue.

2. The strip is not flat or has bubbles

If the PVC waterproof sealing strip does not fit the surface smoothly during installation, or bubbles appear, it may be caused by improper operation. At this time, you can use a scraper to gently flatten the strip to remove the bubbles. If the PVC waterproof sealing strip itself is soft, you can also heat the strip appropriately to make it softer and easier to adjust.

3. The strip is too long or too short

Sometimes due to inaccurate measurement, the PVC waterproof sealing strip may be too long or too short. The solution to this problem is to re-measure and cut the appropriate length before installation. If the strip is too long, you can trim it with scissors; if it is too short, you need to re-cut it.

4. The strip is damaged or aged

After long-term use, the PVC sealing strip may age, harden or be damaged, affecting its sealing effect. At this time, you need to check the status of the sealant regularly and replace it in time if you find any problems. For areas with harsh external environments, you can choose PVC waterproof sealing strips that are resistant to aging and UV rays.

Dongguan Tingjie Decoration Materials Co., Ltd. – Your Trusted Edge Banding Supplier

At Dongguan Tingjie Decoration Materials Co., Ltd., we are committed to providing premium edge banding materials at the best prices. As a reliable manufacturer based in Dongguan, China, we offer a wide range of edge banding solutions including PVC waterproof sealing tape, ABS, and wood grain varieties, available in both T-type and U-type profiles. We offer attractive promotions and discounts for bulk purchasing, making us an excellent choice for those looking for affordable yet high-quality edge banding products. Get in touch today for custom orders, free quotes, or any inquiries regarding our products.