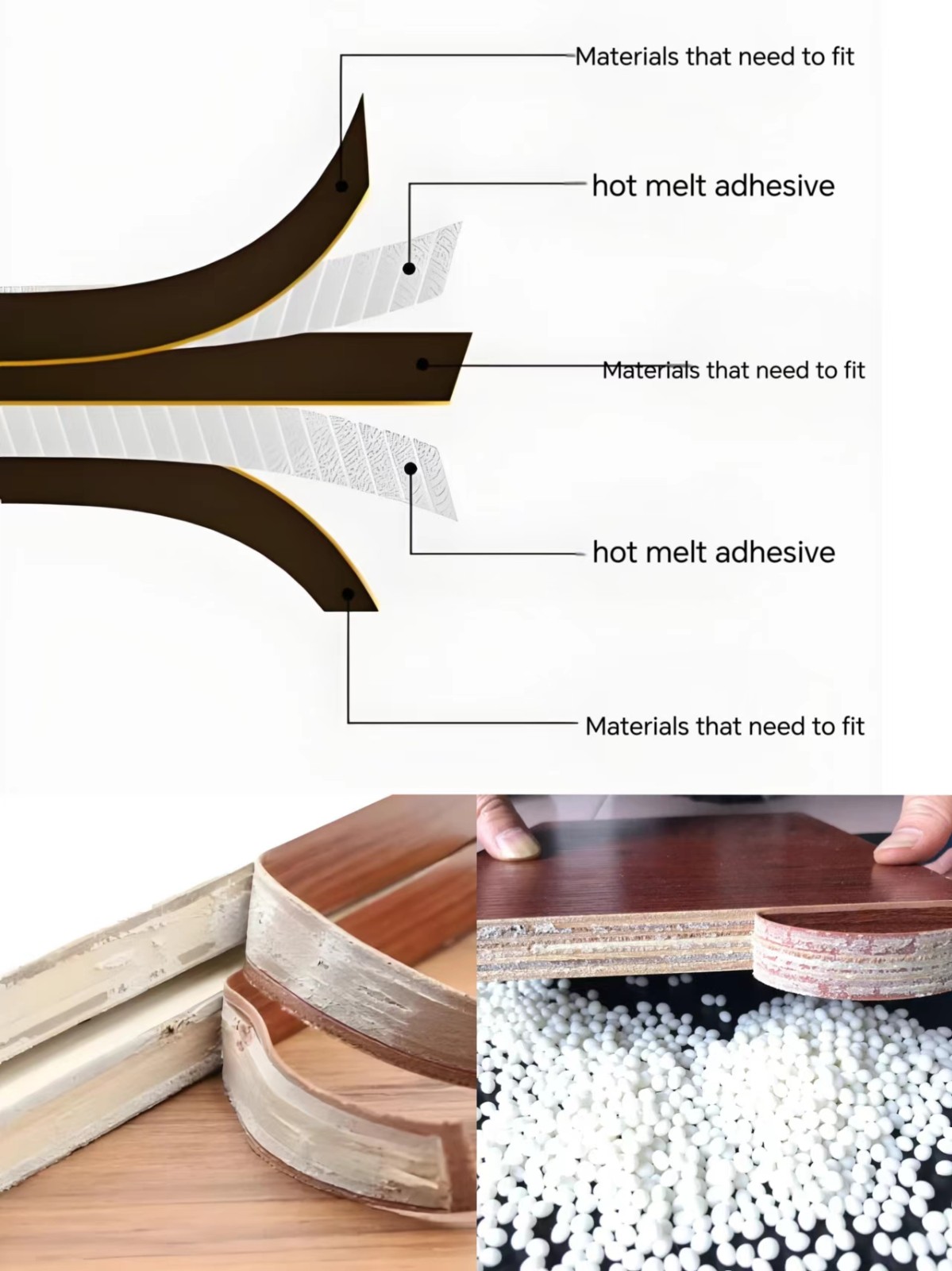

Hot melt adhesive is a commonly used industrial adhesive widely used in manufacturing, packaging, electronics, furniture making and other fields. The main advantages of hot melt glue are its fast bonding ability, solvent-free environmental protection and strong bonding force. Usually, hot melt adhesive is heated to a certain temperature to make it melt and become viscous, so as to perform bonding work. Different types of hot melt glue, such as EVA hot melt adhesive and PUR hot melt glue, have different softening characteristics, application scenarios and softening methods. In actual use, understanding how to effectively soften these hot melt glues is crucial to ensure bonding quality, operating efficiency and safety.

This article will explore in depth how to soften EVA hot melt glue and PUR hot melt glue, and analyze the principles and methods of softening hot melt glue in detail.

What is the principle of hot melt adhesive?

Hot melt adhesive is a material that softens and melts when heated, usually composed of a variety of chemicals such as resin, plasticizer, stabilizer, etc. When hot melt adhesive is heated to its softening point, the bond between molecules relaxes, causing it to change from a solid state to a viscous liquid state. At this time, the hot melt adhesive has strong adhesion ability and can quickly bond two surfaces together.

Different types of hot melt glue have different melting points and softening temperatures. The softening degree of hot melt glue directly affects its application effect, such as bonding strength, temperature resistance and stability after bonding.

How to soften hot melt glue?

What is EVA hot melt glue?

EVA hot melt glue is a widely used hot melt adhesive, which is usually used in many fields such as packaging, toy manufacturing, and furniture edge banding. EVA hot melt glue is characterized by low melting point, good adhesion and strong adaptability, making it suitable for operation in low temperature environments. It is usually softened and melted in the temperature range of 100℃-120℃.

EVA hot melt glue softening method:

Heating temperature control

EVA hot melt glue has a low softening temperature, so make sure the temperature is moderate when heating. Generally speaking, the melting temperature of EVA hot melt glue is about 100℃ to 120℃. If the heating temperature is too high, it may cause bubbles or burns in the hot melt adhesive, affecting the bonding performance of the glue. When using a hot melt adhesive gun, the temperature should be set according to the marked temperature of the adhesive strip to avoid overheating.

Using a hot melt glue gun

The hot melt glue gun is the most common tool for softening and using EVA hot melt adhesive. By controlling the heating temperature of the hot melt glue gun, it is possible to ensure that the EVA hot melt glue softens at the appropriate temperature to achieve the best bonding effect. During the softening process, it is recommended to preheat the hot melt glue gun until the adhesive strip can flow out smoothly. If it is found that the adhesive strip is not easy to flow out, the temperature can be appropriately increased, but overheating should be avoided.

Temperature control heating system

In the industrial production process, a temperature control heating system is usually used to control the heating process of EVA hot melt glue. This method can ensure the uniformity and stability of the temperature, thereby avoiding overheating or overcooling of the hot melt adhesive. This type of temperature control heating system is widely used in packaging, electronic product assembly and other fields.

Avoid excessive temperature

When softening EVA hot melt glue, excessively high temperatures may cause degradation of the glue and affect the bonding performance. In order to ensure the quality of the glue, it should be controlled between 100℃ and 120℃. During the heating process, the temperature can be monitored by a thermometer or temperature control equipment to ensure that the glue is in an ideal softening state.

Precautions for softening EVA hot melt glue:

● Make sure the temperature of the heater is moderate and avoid overheating.

● Different brands and models of EVA hot melt glue may have different softening temperature requirements. When using, refer to the technical information provided by the manufacturer.

● When softening the glue, make sure the glue gun and heating equipment are clean to prevent impurities from entering the hot melt adhesive and affecting the bonding effect.

● When using, avoid long-term heating to prevent the hot melt adhesive from losing its bonding strength.

What is PUR hot melt glue?

PUR hot melt glue is a hot melt glue that is widely used in many high-demand industrial fields. Unlike EVA hot melt glue, PUR hot melt glue has higher temperature resistance and strong bonding strength, so it is often used in fields that require higher bonding strength, high temperature resistance and chemical corrosion resistance. The melting point of PUR hot melt glue is usually between 150℃ and 190℃, and it has the characteristics of rapid hardening after heating.

Softening method of PUR hot melt glue:

Use special heating equipment

Due to the high melting point of PUR hot melt adhesive, more professional equipment is needed for heating. Generally speaking, PUR hot melt glue is softened by high-temperature hot melt glue guns, spray systems or liquid heaters. In these devices, the heater provides a stable temperature to ensure that the PUR hot melt glue can melt evenly.

Heating temperature control

The melting temperature of PUR hot melt adhesive is relatively high, so more precise temperature control equipment is required to avoid excessive temperature causing thermal degradation of the glue. The softening temperature of PUR hot melt glue is approximately between 150℃ and 190℃. In order to ensure efficient and stable use of PUR hot melt glue, heating equipment that can accurately adjust the heating temperature is usually selected to avoid the glue losing its adhesion during the heating process.

Liquid heating system

In industrial applications, PUR hot melt glue is often heated by a liquid heating system, which can ensure the temperature stability of the glue during the heating process and can automatically adjust the heating system to meet different production needs. The liquid heating system uses heat exchange technology to ensure that the PUR hot melt glue reaches the best state in terms of fluidity and adhesion.

Precautions for softening PUR hot melt glue:

● Due to the high melting point of PUR hot melt adhesive, special attention should be paid to temperature control during heating to avoid overheating or uneven cooling of the glue.

● During the softening process, it is necessary to avoid sudden temperature rises and falls, which may affect the fluidity and bonding properties of PUR hot melt glue.

● The softened PUR hot melt glue needs to be used quickly to avoid long-term exposure to high temperatures, which may cause degradation of the glue performance.

Comparison between EVA hot melt glue and PUR hot melt glue

Softening temperature

● The softening temperature of EVA hot melt glue is relatively low, generally between 100℃-120℃, which is suitable for the bonding needs of daily small furniture, packaging and other industries.

● PUR hot melt glue has a high softening temperature, generally between 150℃-190℃, and is suitable for applications that require high bonding strength and high temperature resistance, such as automotive parts, electronic products, etc.

Adhesion performance

● EVA hot melt glue has good fluidity and strong adhesion, and is suitable for a wide range of general bonding tasks.

● PUR hot melt glue is widely used in more demanding industrial bonding tasks due to its excellent temperature resistance, chemical resistance and strong bonding strength.

Why Choose Tingjie as Your Hot Melt Glue and Edge Banding Supplier?

Tingjie, established in 2024 and located in Guangdong, China, is a leading manufacturer and supplier of industrial hot melt adhesive, ABS edge banding, and PVC edge banding. Our factory is equipped with advanced machinery and staffed by experienced professionals, ensuring an annual production capacity of 10,000 tons. We specialize in customized solutions for cabinetry and furniture panels. As a trusted China-based company, we supply high-quality products to customers across Europe, the Middle East, and Vietnam. Looking for a wholesale supplier with low prices and bulk purchasing options? Contact Tingjie today for the best factory quotes and promotions.