Tingjie Redefines Cabinetry Excellence with 9mm ABS Edge Banding

In the realm of cabinet manufacturing, precision and quality are paramount, and few components play a more critical role than edge banding. As a leader in the industry, Tingjie has set a new benchmark with its 9mm ABS edge banding, a solution that marries durability, versatility, and aesthetic appeal to elevate cabinet edge banding standards across the board. For manufacturers and designers alike, the choice of edge banding can transform a functional cabinet into a long-lasting, visually striking piece—and Tingjie’s 9mm ABS edge banding is emerging as the gold standard.

At the core of Tingjie’s innovation is its 9mm ABS edge banding, a product engineered to address the unique challenges of modern cabinetry. The 9mm width is a deliberate design choice, offering enhanced coverage that protects thicker panels from daily wear, moisture, and impact—common culprits that can compromise a cabinet’s integrity over time. Unlike narrower alternatives, 9mm ABS edge banding provides a robust barrier, ensuring that even high-traffic cabinets in kitchens, bathrooms, or offices maintain their structural and visual appeal for years. For Tingjie, this focus on functionality is non-negotiable: “Our 9mm ABS edge banding is built to withstand the rigors of daily use, from busy family kitchens to commercial spaces,” notes a company spokesperson. “It’s not just about looks—it’s about longevity.”

At the core of Tingjie’s innovation is its 9mm ABS edge banding, a product engineered to address the unique challenges of modern cabinetry. The 9mm width is a deliberate design choice, offering enhanced coverage that protects thicker panels from daily wear, moisture, and impact—common culprits that can compromise a cabinet’s integrity over time. Unlike narrower alternatives, 9mm ABS edge banding provides a robust barrier, ensuring that even high-traffic cabinets in kitchens, bathrooms, or offices maintain their structural and visual appeal for years. For Tingjie, this focus on functionality is non-negotiable: “Our 9mm ABS edge banding is built to withstand the rigors of daily use, from busy family kitchens to commercial spaces,” notes a company spokesperson. “It’s not just about looks—it’s about longevity.”

ABS edge banding, in general, has long been favored in the industry for its exceptional properties, and Tingjie’s iteration takes this to the next level. ABS (Acrylonitrile Butadiene Styrene) is celebrated for its resistance to heat, chemicals, and impact, making it ideal for environments where cabinets face frequent use. Tingjie’s ABS edge banding is crafted from premium-grade resin, ensuring consistency in texture and performance across every roll. The material’s flexibility allows it to adhere seamlessly to various panel types, including MDF, particleboard, and plywood, eliminating gaps that can trap moisture or dirt. This versatility makes ABS edge banding a go-to choice for manufacturers seeking a reliable, all-purpose solution—and Tingjie’s commitment to quality ensures its ABS edge banding stands out in a crowded market.

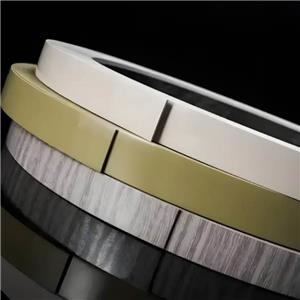

Cabinet edge banding is more than a protective layer; it’s a design element that ties a cabinet’s look together.Cabinet edge banding seals cabinet edges, fending off moisture and wear. Tingjie understands this, which is why its 9mm ABS edge banding is available in a vast array of finishes, from realistic wood grains to sleek solids and metallic tones. This diversity allows designers to match cabinet edge banding to any interior style, whether rustic, modern, or industrial. The precision of Tingjie’s manufacturing process ensures that each 9mm ABS edge banding strip has a smooth, uniform surface, free from defects that could mar the cabinet’s appearance. For homeowners and businesses, this means cabinets that not only perform well but also elevate the overall aesthetic of a space.

What truly sets Tingjie’s 9mm ABS edge banding apart is its attention to detail in production. The company uses advanced extrusion technology to create 9mm ABS edge banding that is both strong and easy to work with. Manufacturers appreciate that Tingjie’s ABS edge banding cuts cleanly, reducing waste and streamlining the assembly process. Its superior adhesion properties mean that cabinet edge banding stays firmly in place, even after years of use, minimizing the need for repairs or replacements. This reliability translates to cost savings for manufacturers and peace of mind for customers, solidifying Tingjie’s reputation as a trusted provider of high-quality edge banding solutions.

Sustainability is another cornerstone of Tingjie’s approach to producing 9mm ABS edge banding. The company is committed to reducing its environmental impact by using recycled materials in its ABS edge banding where possible and optimizing its manufacturing processes to conserve energy. This eco-conscious focus resonates with modern consumers and businesses, who increasingly prioritize sustainable products. By choosing Tingjie’s 9mm ABS edge banding, manufacturers can align their offerings with green initiatives without sacrificing quality—a win-win for both the planet and their bottom line.

The demand for premium cabinet edge banding has grown significantly in recent years, driven by a surge in home renovations and commercial construction. As consumers seek cabinets that are both durable and stylish, Tingjie’s 9mm ABS edge banding has become a top choice. Contractors and designers praise its consistency, noting that it simplifies their workflow and ensures a flawless finish. “Tingjie’s 9mm ABS edge banding has become a staple in our projects,” says a leading interior designer. “It’s reliable, versatile, and enhances the overall quality of the cabinets we install. Our clients notice the difference.”

Tingjie’s dedication to innovation ensures that its 9mm ABS edge banding remains at the forefront of the industry. The company invests in research and development to refine its ABS edge banding formulations, exploring new textures, colors, and performance enhancements to meet evolving market needs. Whether it’s developing antimicrobial 9mm ABS edge banding for healthcare facilities or fire-retardant options for commercial spaces, Tingjie is committed to pushing the boundaries of what cabinet edge banding can achieve.

In summary, Tingjie’s 9mm ABS edge banding is more than a product—it’s a testament to the company’s commitment to excellence. By combining the durability of ABS edge banding with the practicality of a 9mm width and the versatility required for modern cabinet edge banding, Tingjie has created a solution that meets the demands of manufacturers, designers, and consumers alike. As the cabinetry industry continues to evolve, Tingjie’s 9mm ABS edge banding stands ready to shape its future—one precision-crafted strip at a time.