Whether it is automobile manufacturing, construction, or home appliances, furniture, packaging and other industries, the application of industrial hot glue is constantly expanding. Among various industrial hot glue products, PUR industrial hot glue has become an important material in the industry due to its excellent performance, reliable bonding strength and durability.

Starting with the question "What does PUR stand for in PUR industrial hot glue?", this article will explore the definition of PUR, its application in the field of industrial hot glue and the technical background of this material.

What is PUR?

PUR stands for "polyurethane". Polyurethane is a polymer material generated by the reaction of organic diisocyanate and polyol, which has excellent mechanical properties and chemical stability. Its molecular structure can be adjusted as needed to obtain polyurethane materials with different performance requirements such as hardness, elasticity, temperature resistance, etc. PUR is a very versatile polymer that is widely used in coatings, foams, plastics, rubber and other fields.

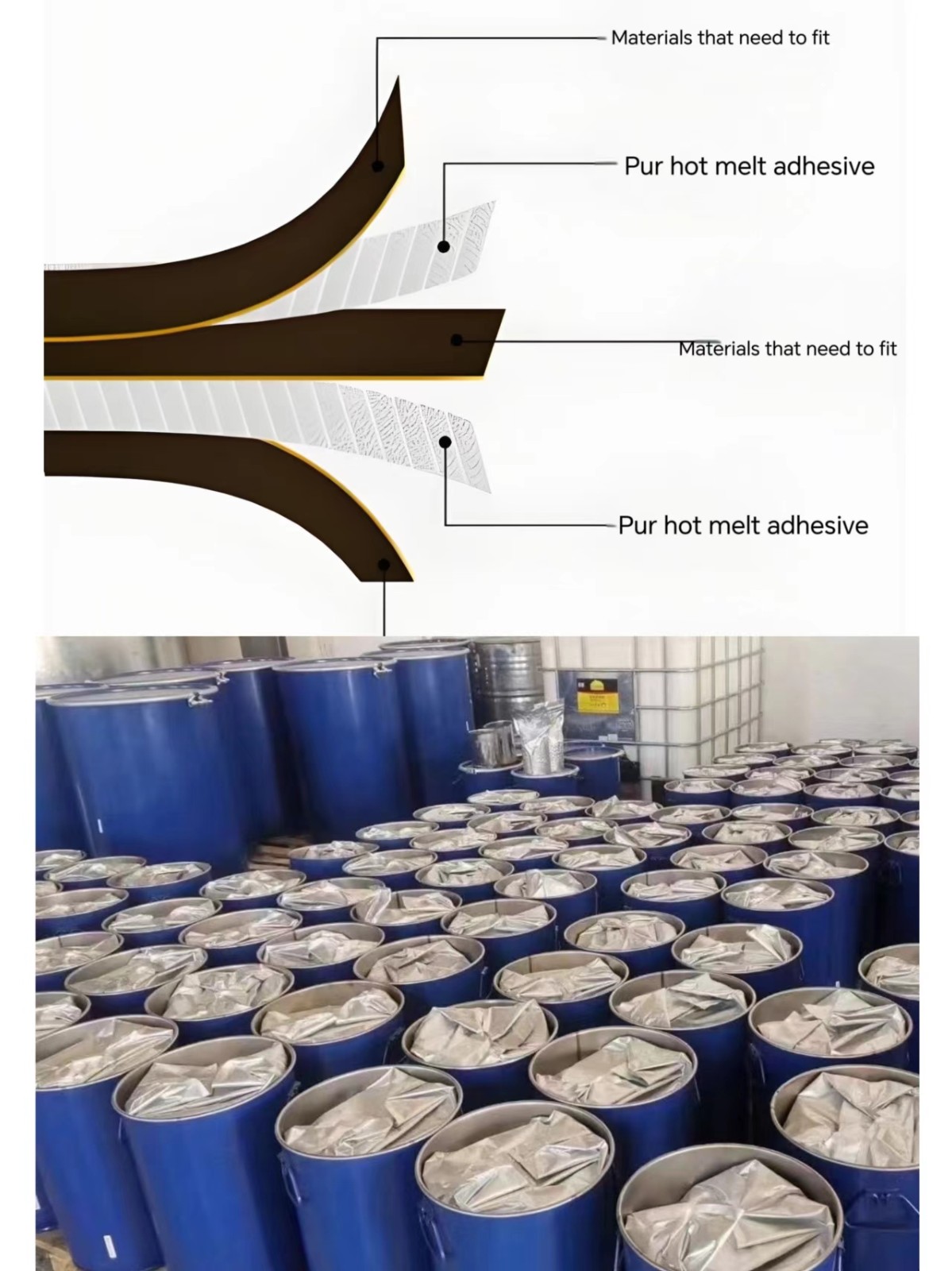

Polyurethane adhesive (PUR industrial hot glue) is a special application form of polyurethane material. It is melted into liquid by heating and then applied to the surface to be bonded. During the cooling and curing process, the polyurethane molecules form a high-strength bonding layer through chemical bonding. PUR hot melt adhesive occupies an important position in the hot melt adhesive market. Its high performance makes it an ideal bonding material in many environments that require high temperature resistance, chemical corrosion resistance, and wear resistance.

What is the chemical principle of PUR industrial hot glue?

The basic principle of polyurethane hot melt adhesive involves the chemical properties of its polymer. PUR hot melt adhesive is usually composed of polyurethane polymers, plasticizers, additives, stabilizers and other ingredients. During the manufacturing process, the reactive groups of polyurethane (such as isocyanate groups) react with polyols to form a polyurethane chain structure.

When PUR industrial hot glue is heated to a certain temperature, it will change from a solid state to a flowing liquid state, with good fluidity and adhesion, and can quickly adhere to the surface of various materials. During the cooling process, the liquid glue will quickly solidify and form a strong bonding layer. This process not only depends on the physical properties of the glue itself, but also needs to consider the performance of the glue in multiple stages such as heating, melting, cooling and curing.

In addition, PUR industrial hot glue also has a certain self-crosslinking ability. During the curing process, the chemical groups in PUR industrial hot glue form a three-dimensional network structure through crosslinking reaction, thereby improving the mechanical properties and durability of the bond. This makes PUR hot melt adhesive show better bonding strength and durability compared with traditional hot melt adhesives (such as EVA, PE, etc.).

What are the advantages of PUR industrial hot glue?

As a high-performance adhesive, polyurethane hot melt adhesive (PUR industrial hot glue) has many unique advantages, which makes it widely used in industrial production.

Advantages of PUR industrial hot glue:

1. High bonding strength

2. High temperature and chemical resistance

3. Good durability and anti-aging

4. Strong environmental adaptability

5. Solvent-free and low emissions

● High bonding strength: PUR industrial hot glue has stronger bonding strength than other traditional hot melt adhesives. The structure of the polyurethane molecular chain can be quickly crosslinked after cooling to form a strong molecular chain network, which makes PUR industrial hot glue have strong adhesion. Whether it is on glass, metal, wood, plastic and other materials, PUR hot melt adhesive can provide stable bonding strength.

● High temperature and chemical resistance: Polyurethane itself has good high temperature resistance and can maintain its physical properties unchanged in high temperature environments. PUR industrial hot glue can withstand high temperature changes in application and adapt to different working environments. Moreover, the chemical resistance of PUR industrial hot glue also enables it to withstand the erosion of chemicals such as oil, acid, and alkali in many special applications, and is widely used in automobiles, electronics, construction and other fields.

● Good durability and anti-aging: The structure of PUR hot melt adhesive determines that it has good durability during long-term use. The molecular structure of polyurethane materials can resist the influence of environmental factors such as ultraviolet radiation and oxidation, and avoid aging and performance degradation of the glue layer. Therefore, PUR industrial hot glue is widely used in industries that require long-term stable bonding.

● Strong environmental adaptability: Polyurethane hot melt adhesive has strong adaptability and can maintain good bonding effects under high humidity, low temperature and different climatic conditions. Many traditional hot melt adhesives tend to lose their adhesion in extreme environments, while PUR industrial hot glue can ensure stable use under these environmental conditions.

● Solvent-free and low-emission: PUR hot melt adhesive is a solvent-free adhesive, which means that it does not release harmful gases during the curing process and is therefore environmentally friendly. In many industries that need to consider environmental regulations, PUR industrial hot glue provides a greener and safer alternative.

What are the application areas of PUR industrial hot glue?

The wide application of polyurethane hot melt adhesive covers many industries, especially those that require high adhesive properties, durability, and chemical stability. Here are some typical application scenarios:

● Automotive industry: In the automobile manufacturing process, PUR industrial hot glue is mainly used for bonding parts inside and outside the car. For example, bonding of automotive interior parts, dashboards, and seals. The high strength, high temperature resistance, and chemical resistance of PUR industrial hot glue make it perform well in these complex environments. In addition, PUR hot melt adhesive can also be used for automotive window glass bonding, fixing of external lamps, etc.

● Electronic products: Electronic products have very high requirements for glue during the production process, especially when bonding screens, keyboards, casings and other components. PUR hot melt adhesive provides reliable bonding effects. Its excellent temperature resistance and moisture resistance also ensure the stability of electronic equipment in high temperature and high humidity environments.

● Packaging industry: In the production of packaging materials, PUR industrial hot glue is widely used for the bonding of packaging materials such as cartons, paper boxes, and plastic bags. Due to its high bonding strength and excellent water resistance, PUR hot melt adhesive is often used to deal with packaging needs that need to withstand high pressure or high humidity.

● Furniture manufacturing: The furniture industry has strict requirements for bonding materials. PUR industrial hot glue has become an ideal choice for materials such as wood, leather, and cloth due to its strong bonding strength and high durability. It not only provides long-lasting fixation for different parts of furniture, but also will not loosen or peel off during long-term use.

● Construction industry: In the construction industry, PUR industrial hot glue is used to seal, bond and reinforce building materials. Especially in the bonding of materials such as glass and aluminum alloy, PUR hot melt adhesive can effectively provide a stable fixation effect, helping to improve the safety and durability of buildings.

Manufacturing and quality control of PUR industrial hot glue

The production of PUR industrial hot glue requires strict quality control. Since it involves high-demand performance indicators in a variety of industrial applications, manufacturers usually carry out precise control in terms of raw material selection, manufacturing process, product testing, etc.

● Raw material selection: The quality of polyurethane hot melt adhesive is directly related to the selection of its raw materials. Usually, manufacturers will choose high-quality isocyanates, polyethers or polyester polyols as the main components of polyurethane adhesives. The purity, source and performance of the raw materials will affect the quality of the final product.

● Production process: The production of PUR hot melt adhesive usually adopts the melting method, which heats the polyurethane polymer to an appropriate temperature to achieve the ideal fluidity. The temperature and time need to be strictly controlled during the production process to ensure the integrity of the chemical structure of the material and prevent the generation of excessive volatile components.

● Quality control: Manufacturers will conduct multiple quality tests during the production process to ensure that PUR industrial hot glue has the required bonding strength, fluidity, cooling time and other properties. Common testing items include bonding strength test, thermal stability test, tensile strength test, etc., to ensure that the products meet industry standards.

Buy Wholesale Edge Banding at Competitive Prices – Dongguan Tingjie

Dongguan Tingjie Decoration Materials Co., Ltd. is your one-stop supplier for all edge banding needs. With years of experience, we offer a broad selection of high-quality edge banding materials such as PVC, ABS, wood grain, and T-type and U-type profiles. Based in Dongguan, China, we supply bulk orders at discounted prices to clients worldwide. Our factory can accommodate large-scale orders with flexible customization options, making us an ideal manufacturer for your business. We also provide wholesale prices and free quotes to ensure you get the best deals on your next purchase.