Tingjie Redefines Precision with 3mm Edge Banding, Laser Edge Band, and Laser Wood Grain Edge Banding

In the competitive landscape of furniture manufacturing, precision and aesthetics are non-negotiable. As brands strive to deliver products that blend durability with visual appeal, the role of edge banding has never been more critical. Leading this charge is Tingjie, a company at the forefront of innovation, whose 3mm edge banding, laser edge band, and laser wood grain edge banding solutions are setting new industry standards. These three technologies, each a testament to Tingjie’s commitment to excellence, are transforming how manufacturers approach edge finishing, offering unmatched versatility, precision, and beauty.

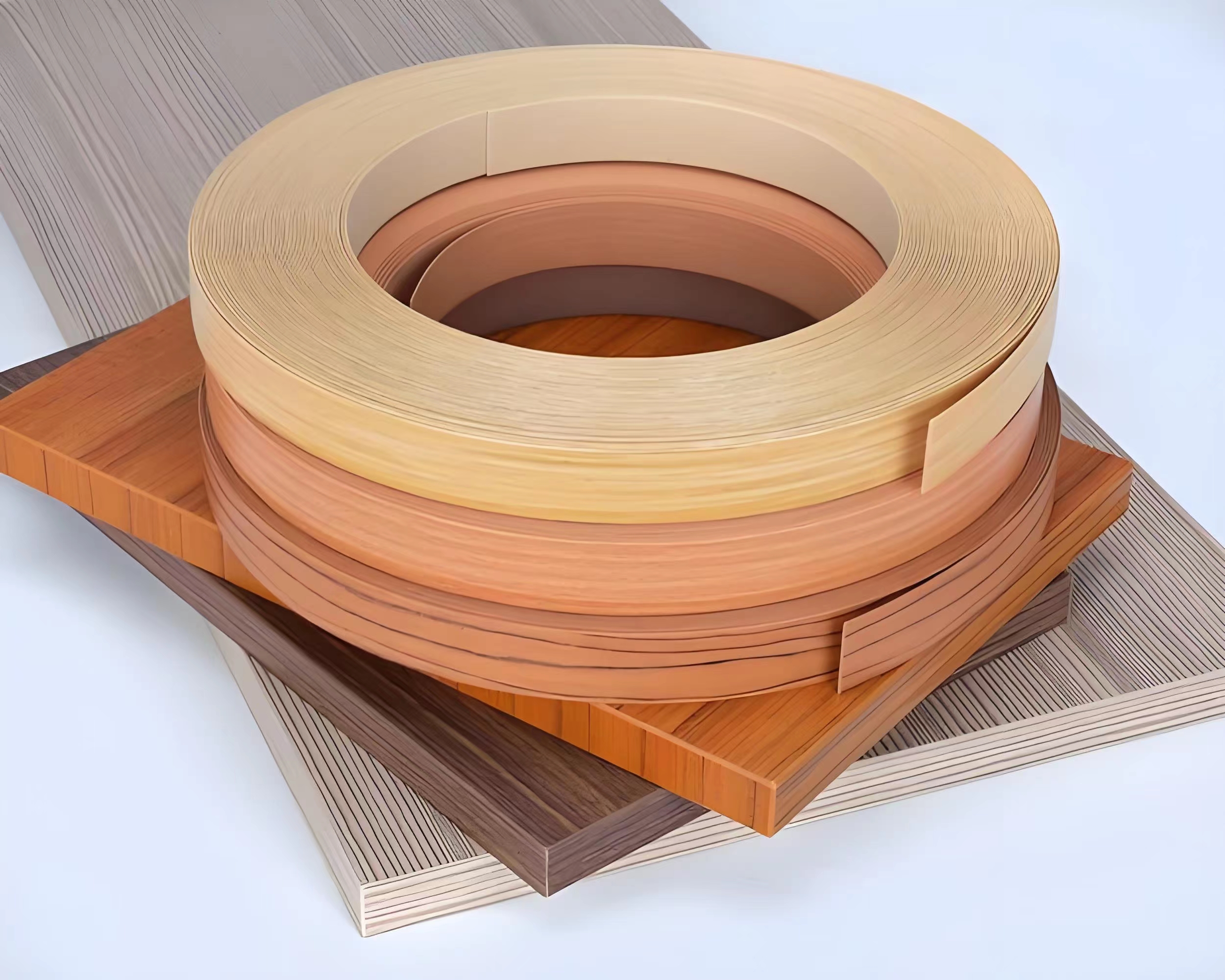

3mm edge banding, a staple in Tingjie’s portfolio, has emerged as a game-changer for its perfect balance of thickness and flexibility. Unlike thinner alternatives that may lack durability or thicker options that limit design flexibility, 3mm edge banding provides robust protection against impacts, moisture, and daily wear—essential for high-traffic furniture like kitchen cabinets, office desks, and dining tables. Tingjie’s 3mm edge banding is crafted from premium materials, including PVC, ABS, and wood veneer, each engineered to withstand the rigors of daily use while maintaining a sleek finish. What makes 3mm edge banding particularly popular is its adaptability: it seamlessly adheres to both straight and curved edges, allowing manufacturers to explore diverse designs without compromising on quality. Whether applied to particleboard, MDF, or plywood, 3mm edge banding from Tingjie ensures a consistent, professional look that elevates the overall value of the furniture.

3mm edge banding, a staple in Tingjie’s portfolio, has emerged as a game-changer for its perfect balance of thickness and flexibility. Unlike thinner alternatives that may lack durability or thicker options that limit design flexibility, 3mm edge banding provides robust protection against impacts, moisture, and daily wear—essential for high-traffic furniture like kitchen cabinets, office desks, and dining tables. Tingjie’s 3mm edge banding is crafted from premium materials, including PVC, ABS, and wood veneer, each engineered to withstand the rigors of daily use while maintaining a sleek finish. What makes 3mm edge banding particularly popular is its adaptability: it seamlessly adheres to both straight and curved edges, allowing manufacturers to explore diverse designs without compromising on quality. Whether applied to particleboard, MDF, or plywood, 3mm edge banding from Tingjie ensures a consistent, professional look that elevates the overall value of the furniture.

Complementing its 3mm edge banding, Tingjie’s laser edge band technology represents a leap forward in edge bonding precision. Laser edge band eliminates the need for traditional adhesives, instead using laser heat to activate a specialized coating on the edge band, creating a molecular bond with the panel. This process results in an almost invisible seam, far superior to the visible glue lines of conventional methods. Laser edge band from Tingjie is celebrated for its strength—resistant to peeling, warping, and moisture—and its efficiency, streamlining production lines with faster application times and reduced waste. The technology’s adaptability is another key advantage: laser edge band works seamlessly with 3mm edge banding, enhancing its durability while maintaining the thin profile that designers love. For manufacturers, laser edge band means fewer defects, higher throughput, and furniture that meets the strictest quality standards, making it a cornerstone of Tingjie’s offerings.

Taking aesthetics to new heights, Tingjie’s laser wood grain edge banding marries the precision of laser technology with the natural beauty of wood. Laser wood grain edge banding is designed to replicate the intricate patterns, textures, and color variations of real wood, from oak and maple to walnut and teak. What sets it apart is its ability to align perfectly with wood-grain panels, ensuring the edge flows seamlessly into the surface—no mismatched patterns, no jarring transitions. This level of detail is made possible by advanced laser engraving, which etches grain patterns directly onto the edge band, creating a depth and realism that standard prints cannot match. Laser wood grain edge banding pairs exceptionally well with 3mm edge banding, as the 3mm thickness provides enough surface area to showcase the detailed grain, making it ideal for high-end furniture where authenticity is paramount.

Tingjie’s focus on innovation is evident in how it integrates 3mm edge banding, laser edge band, and laser wood grain edge banding into cohesive solutions for manufacturers. For example, a kitchen cabinet manufacturer can use 3mm edge banding for its durability, apply laser edge band for a seamless bond, and finish with laser wood grain edge banding to match the cabinet’s oak paneling—resulting in a product that looks like solid wood but is more affordable and durable. This versatility has made Tingjie a go-to partner for brands ranging from budget-friendly retailers to luxury furniture designers.

Sustainability is another area where Tingjie’s technologies excel. 3mm edge banding is often made from recycled materials, reducing waste, while laser edge band eliminates the need for chemical adhesives, lowering volatile organic compound (VOC) emissions. Laser wood grain edge banding, meanwhile, reduces reliance on rare or expensive hardwoods, allowing manufacturers to achieve a premium look using more sustainable materials. These eco-friendly features resonate with today’s consumers, who increasingly prioritize sustainability in their purchasing decisions.

need for chemical adhesives, lowering volatile organic compound (VOC) emissions. Laser wood grain edge banding, meanwhile, reduces reliance on rare or expensive hardwoods, allowing manufacturers to achieve a premium look using more sustainable materials. These eco-friendly features resonate with today’s consumers, who increasingly prioritize sustainability in their purchasing decisions.

Tingjie’s commitment to quality control ensures that every roll of 3mm edge banding, every laser edge band application, and every sheet of laser wood grain edge banding meets![]() rigorous standards. The company’s state-of-the-art production facilities use automated systems to monitor thickness, color consistency, and bonding strength, ensuring uniformity across batches. This attention to detail has earned Tingjie certifications from global organizations, reinforcing its reputation as a trusted provider of edge banding solutions.

rigorous standards. The company’s state-of-the-art production facilities use automated systems to monitor thickness, color consistency, and bonding strength, ensuring uniformity across batches. This attention to detail has earned Tingjie certifications from global organizations, reinforcing its reputation as a trusted provider of edge banding solutions.

As the furniture industry evolves, Tingjie continues to innovate, refining its 3mm edge banding to offer new colors and textures, enhancing laser edge band technology for faster production speeds, and expanding its laser wood grain edge banding range to include more exotic wood species. The company also provides comprehensive support to manufacturers, offering training on how to best integrate 3mm edge banding, laser edge band, and laser wood grain edge banding into their production lines, ensuring they maximize efficiency and quality.

In a market where differentiation is key, Tingjie’s 3mm edge banding, laser edge band, and laser wood grain edge banding give manufacturers the tools to create furniture that stands out. These technologies not only improve product durability and aesthetics but also offer cost savings through reduced waste and increased efficiency. As consumer demands for high-quality, sustainable, and visually appealing furniture grow, Tingjie remains at the forefront, proving that when it comes to edge banding, precision, innovation, and beauty go hand in hand.

For manufacturers looking to elevate their products, Tingjie’s 3mm edge banding, laser edge band, and laser wood grain edge banding are more than just components—they are the foundation of exceptional furniture. With these technologies, the future of furniture manufacturing is not just functional, but extraordinary.