Industrial hot melt glue is widely used in packaging, manufacturing, assembly, automotive, electronics, construction and other industries. They have become an indispensable bonding material in many industries due to their excellent bonding ability, fast curing characteristics and convenient use. Unlike other adhesives, industrial hot melt glue has some unique performance advantages, especially in terms of shelf life and service life. Hot melt adhesive glue generally has longer stability and durability than other adhesives.

This article will take a deep look at the shelf life and service life of industrial hot melt adhesive, analyze the key factors that affect these factors, and discuss how to properly store and use industrial hot melt glue to ensure its optimal performance.

What are the ingredients of industrial hot melt glue?

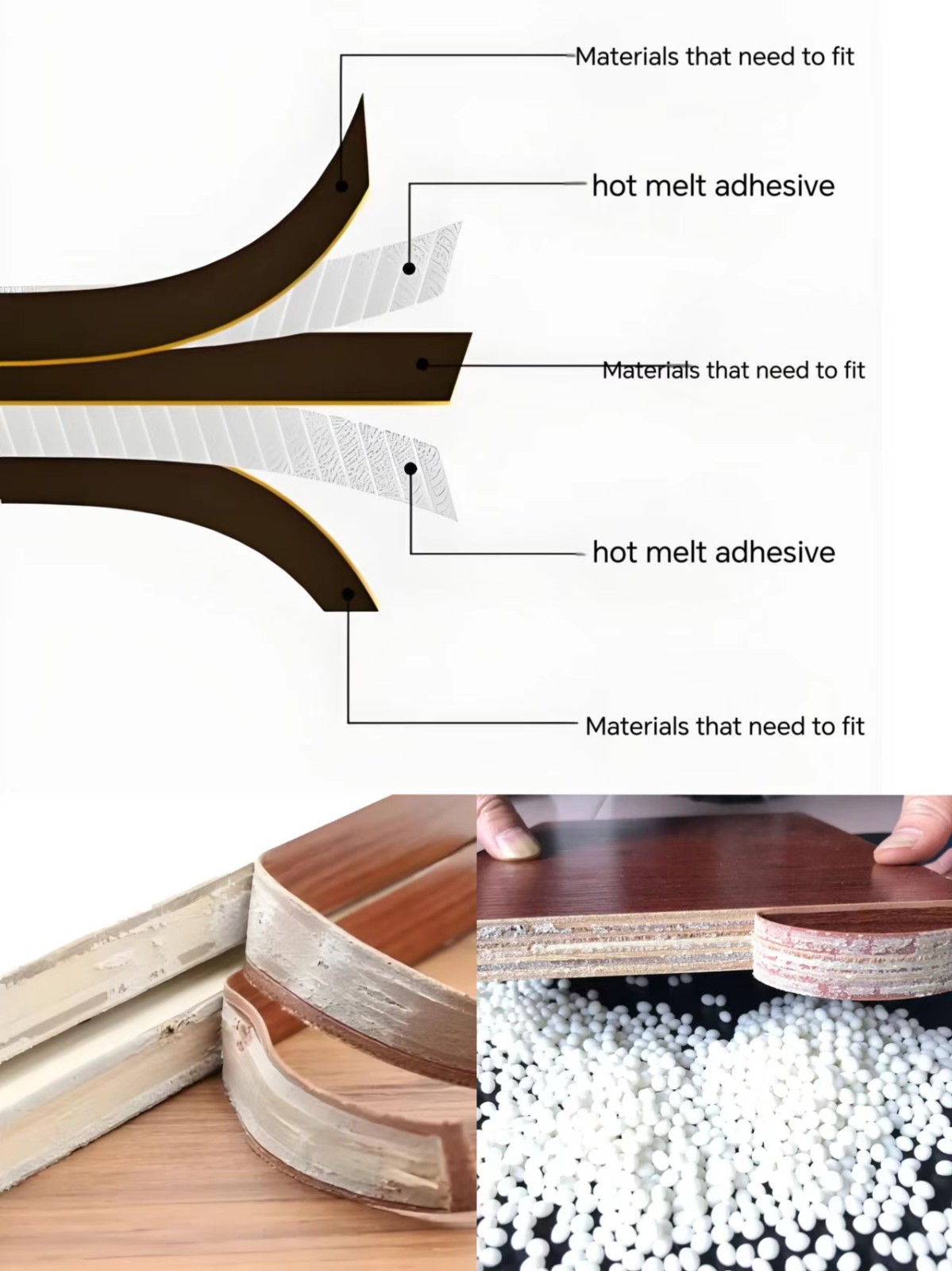

Industrial hot melt glue is an adhesive that melts at high temperature and solidifies after cooling. It is usually composed of resins, waxes, polymers and other ingredients. Unlike solvent-based adhesives, industrial hot melt adhesive does not contain solvents and is 100% solid material. Therefore, when using hot melt adhesive glue, there is no need to worry about the volatilization and influence of solvents. During use, it only relies on temperature changes to adjust its fluidity and adhesion.

Industrial hot melt glue has significant advantages, especially in manufacturing and assembly processes. It can cure quickly, reduce production time, and can bond different types of materials, such as paper, wood, plastic, metal, etc. Its non-toxicity, environmental protection and low cost make it widely used in many industrial applications.

What is the shelf life of industrial hot melt glue?

Under ideal storage conditions, the shelf life of industrial hot melt adhesive can be up to two to three years. Many manufacturers usually indicate the best use date of their products on the packaging, and this date is usually determined based on laboratory test results and long-term tracking of the performance of hot melt glue. However, it is worth noting that the expiration of industrial hot melt glue does not mean that it completely loses its bonding ability after the expiration of the shelf life. More importantly, its performance begins to decline to a certain extent, the bonding force may decrease, and the melting temperature may change.

1. The effect of storage conditions on shelf life

One of the most direct factors affecting the shelf life of industrial hot melt glue is storage conditions. Generally speaking, industrial hot melt glue should be stored in a dry, cool, ventilated environment and avoid exposure to extreme temperature and humidity conditions. High temperature and humid environment will cause chemical changes in the material of hot melt adhesive glue, which may affect its physical properties and bonding effect. Especially in a long-term high temperature or humid environment, industrial hot melt glue may clump, oxidize or deteriorate, resulting in a decrease in its bonding performance.

To extend the shelf life of industrial hot melt adhesive, the ideal storage temperature is usually 5°C to 30°C. The storage location should avoid direct sunlight and ensure that the temperature remains stable. Avoid exposing hot melt adhesive glue to an environment with rapid temperature changes, which may cause the performance of the material to deteriorate.

2. The effect of material type on shelf life

Different types of industrial hot melt glue have different chemical compositions, so their shelf life will also vary. For example, polyurethane (PUR) industrial hot melt glue usually has a long shelf life because its main component has high chemical stability. However, some low-melting-point industrial hot melt adhesives, especially those with resin as the main component, may have a shorter shelf life. The type and composition of hot melt adhesive glue directly determine its stability during storage and its expiration time.

In addition, some industrial hot melt adhesives containing special ingredients (such as plasticizers, stabilizers, etc.) may require more stringent storage conditions to prevent the volatilization or degradation of these ingredients from affecting the bonding effect of the glue. Therefore, manufacturers usually indicate specific storage requirements and optimal use period on the packaging of industrial hot melt glue to ensure the use effect.

3. The impact of packaging method on shelf life

The packaging method of industrial hot melt glue also affects its shelf life. Correct packaging can not only effectively prevent the entry of air and moisture, but also prevent the influence of light and pollutants. Industrial hot melt glue is usually sold in sealed packaging, and airtightness in the packaging bag or container is crucial to maintaining the quality of the glue. If the packaging of hot melt adhesive glue is damaged or not completely sealed, it may cause external environmental factors to have an adverse effect on the glue, thereby shortening its shelf life.

What is the service life of hot melt adhesive glue?

The service life of industrial hot melt adhesive can usually last for several years, but this period depends largely on the environment and conditions of use. For ordinary industrial applications, the service life of hot melt adhesive glue can usually reach three to five years in an environment with moderate temperature and humidity. However, if it is in an environment with high temperature, high humidity or high external force, the service life may be shortened accordingly.

1. Remelting of industrial hot melt glue

An important feature of industrial hot melt glue is that it can be melted and solidified many times without losing adhesive properties. This means that in normal use, industrial hot melt glue can be heated and cooled many times without volatilization or chemical degradation like solvent-based glue. Therefore, the service life of hot melt adhesive glue depends not only on its quality when it is used for the first time, but also on the number of times it can be used repeatedly.

This reusable feature makes hot melt adhesive glue particularly suitable for many industrial applications, especially in production lines that need to frequently handle different materials. In this environment, the continuity of service life reduces costs for enterprises and improves production efficiency.

2. The impact of environmental factors on service life

Although the service life of industrial hot melt adhesive is relatively long, environmental factors such as temperature, humidity, and pollutants still affect the performance of hot melt adhesive glue. For example, industrial hot melt adhesive may become too soft in a high temperature environment, resulting in a decrease in bonding strength or even failure. Therefore, when using it, you should pay attention to the temperature adaptability range of the industrial hot melt glue used, and avoid using it in an environment beyond its design temperature range.

3. The impact of application materials and uses on service life

The service life of industrial hot melt glue is also closely related to the materials and uses to which it is applied. For some materials (such as metals, plastics, etc.), the service life of industrial hot melt glue under normal use conditions can be very long. However, in some extreme environments, such as high temperature or high humidity environments, the service life of industrial hot melt adhesive may be affected, and the bonding effect may gradually decrease after a period of time.

For example, when using industrial hot melt glue in a high temperature environment, you should choose an industrial hot melt glue designed for high temperature conditions to avoid softening or losing its adhesive strength under long-term high temperature.

How to extend the shelf life and service life of hot melt adhesive glue?

In order to ensure the best performance of industrial hot melt glue and extend its shelf life and service life, the following points need special attention:

1. Correct storage conditions: As mentioned above, when storing industrial hot melt adhesive, you should follow the storage recommendations provided by the manufacturer. Avoid high temperature, high humidity, direct sunlight, and large temperature fluctuations, which will help extend the shelf life of industrial hot melt glue.

2. Avoid improper operation: During the use of hot melt adhesive glue, excessive heating and prolonged heating may cause its bonding performance to decrease. Therefore, when using industrial hot melt glue, the heating temperature should be strictly controlled and ensure that it is used within the specified temperature range to avoid affecting its service life.

3. Avoid contact with air and pollutants: Industrial hot melt glue should always be kept sealed and avoid exposure to air, especially in humid environments. If the hot melt adhesive glue surface is exposed for too long, it may absorb moisture or become contaminated, resulting in a decrease in its performance.

Buy hot melt adhesive glue and Edge Banding at Low Prices

Looking for affordable edge banding solutions? Dongguan Tingjie Decoration Materials Co., Ltd. manufactures and supplies high-quality hot melt adhesive glue and edge banding strips products. Based in Dongguan, China, we offer low prices for wholesale orders and discounts on bulk purchases. We also offer customization options to suit your specific needs. As a reliable supplier and manufacturer, we ensure timely delivery and competitive pricing for our customers worldwide.