Edge banding glue is an indispensable component in furniture manufacturing and woodworking industries. It is mainly used to bond edge banding strips to the edges of wood or other materials to ensure its firmness and durability. With the continuous development of technology, the types of edge banding glue are becoming more and more abundant, and various types of edge banding glue have occupied a place in the market.

Especially in modern furniture manufacturing, EVA hot melt glue and PUR hot melt glue have become the most common and important choices due to their superior performance and wide range of applications.

This article will explore the characteristics, applications, advantages and disadvantages of these two types of edge banding glue in depth to help readers better understand and choose edge banding glue products that suit their needs.

EVA hot melt glue: everything you need to know

1.1 What is EVA hot melt glue?

EVA (ethylene-vinyl acetate copolymer) hot melt glue is a hot melt glue made of EVA resin as the base material. It is widely used in furniture edge banding, packaging, electronic products, shoe materials and other industries. EVA hot melt glue has good adhesion, fluidity and transparency. It can quickly melt under heating and form a strong adhesive layer after cooling, ensuring a strong bond between the edge banding and wood or other substrates.

1.2 Characteristics of EVA hot melt glue

● Good adhesion: EVA hot melt glue has excellent adhesion performance and can provide strong bonding between different materials, especially between wood and PVC, ABS and other materials.

● Strong adaptability: EVA hot melt glue has good adaptability and can be melted at a lower temperature, which is suitable for the use of most edge banding machines. Its low melting point makes it less likely to cause damage when used on heat-sensitive materials.

● High transparency: EVA hot melt glue is usually transparent or translucent, suitable for transparent edge banding or situations where the natural color of the edge banding needs to be displayed.

● Environmental protection: EVA hot melt glue is non-toxic and solvent-free, meets environmental protection requirements, and is a relatively safe type of edge banding glue.

● Cost-effectiveness: EVA hot melt glue has a relatively low production cost and good cost-effectiveness, so it is widely used in large-scale furniture production.

1.3 Disadvantages of EVA hot melt glue

● Poor high temperature resistance: EVA hot melt glue has poor high temperature resistance. Long-term exposure to high temperature may cause the bonding strength to decrease or the glue layer to soften, affecting the durability of the product.

● Poor weather resistance: In an environment with high humidity or strong sunlight, the bonding performance of EVA hot melt glue may gradually decrease, causing the edge banding strip to fall off or crack.

● Not suitable for heavy-duty applications: In some applications that require high-strength bonding, the bonding strength of EVA hot melt glue may be insufficient, especially for large-area edge banding or high-load furniture products, a stronger edge banding glue may need to be selected.

1.4 Application areas of EVA hot melt glue

EVA hot melt glue is widely used in the edge banding of mid- and low-end furniture and wood products, especially for products that do not require extreme bonding strength, such as daily home furniture, decorative panels, and some light wood products. EVA hot melt glue is also widely used in furniture manufacturing, paper packaging, shoe materials, electronic products and other industries.

PUR hot melt glue: everything you need to know

2.1 What is PUR hot melt glue?

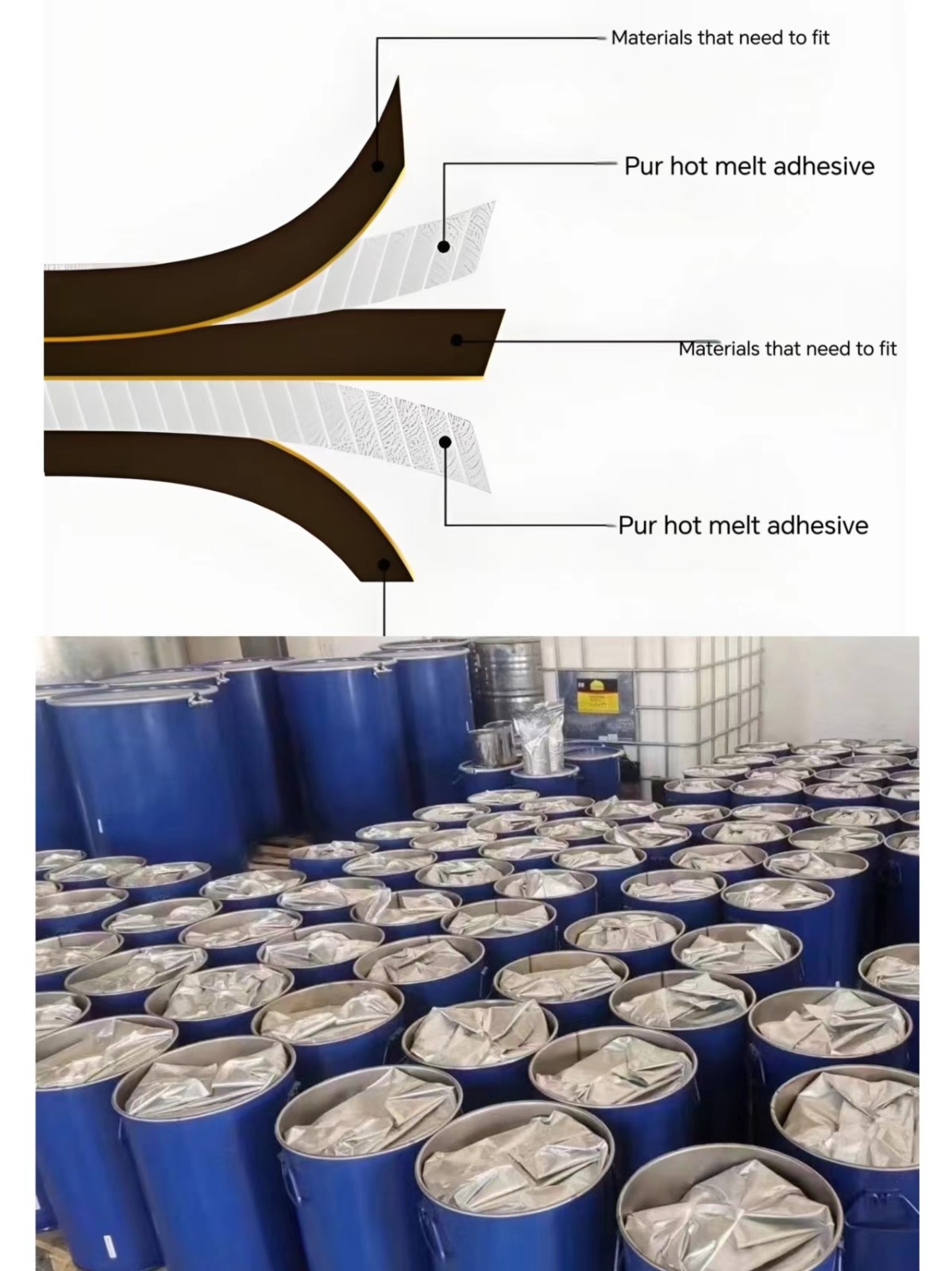

PUR (polyurethane hot melt glue) hot melt glue is a polyurethane-based hot melt glue, which is widely used in high-end furniture and woodworking industries due to its superior bonding performance, temperature resistance and chemical resistance. Compared with EVA hot melt glue, PUR hot melt glue has obvious advantages in bonding strength, weather resistance and high temperature resistance, and has become the first choice of many high-demand furniture manufacturers.

2.2 Characteristics of PUR hot melt glue

● Extremely strong bonding force: PUR hot melt glue can form a very strong bonding force between different surface materials, especially between different materials such as wood, metal, plastic, etc.

● High temperature resistance: PUR hot melt glue has very high high temperature resistance and can maintain stable performance in a high temperature environment. Even under high temperature or direct sunlight, PUR hot melt glue will not soften or fail.

● Chemical resistance: PUR hot melt glue has strong chemical resistance and can withstand the erosion of oil, solvents and other chemicals, and is suitable for some special environmental conditions.

● Excellent weather resistance: PUR hot melt glue has strong weather resistance and can resist the damage of humidity and ultraviolet rays. It is suitable for furniture and decorative materials used outdoors and in harsh environments.

● Environmental protection: PUR hot melt glue is solvent-free and generally does not contain harmful substances, so it meets environmental protection standards and is suitable for modern markets with high environmental protection requirements.

2.3 Disadvantages of PUR hot melt glue

● High cost: Compared with EVA hot melt glue, PUR hot melt glue has a higher production cost and is therefore relatively expensive. This limits its application in some cost-sensitive markets.

● Slow bonding speed: PUR hot melt glue has a relatively slow melting speed, which may cause certain production efficiency problems in large-scale production, especially when fast production is required.

● Requires special equipment: The application of PUR hot melt glue usually requires special edge banding equipment or glue guns, so the investment in equipment is relatively large. For some small and medium-sized furniture manufacturers, the equipment purchase and maintenance costs may increase.

2.4 Application fields of PUR hot melt glue

PUR hot melt glue is suitable for edge banding of high-end furniture, luxury wood products and some special materials. Due to its excellent adhesion and weather resistance, PUR hot melt glue is widely used in some high-demand markets, such as outdoor furniture, high-temperature resistant furniture, medical equipment, and wood products that need to be used for a long time.

EVA hot melt glue vs. PUR hot melt glue: Which is better?

Adhesion and strength

EVA hot melt glue has good bonding properties, but its bonding strength is slightly inferior to that of PUR hot melt glue. PUR hot melt glue can provide stronger bonding between a variety of different materials, especially in the face of high-intensity use environments, PUR hot melt glue performs better.

Temperature resistance and weather resistance

In terms of high temperature resistance and weather resistance, PUR hot melt glue is significantly better than EVA hot melt glue. PUR hot melt glue can still maintain its bonding effect in high temperature environments, while EVA hot melt glue is easy to soften and fail in high temperature environments. In addition, PUR hot melt glue is also resistant to moisture and UV rays, making it suitable for outdoor and harsh environments.

Cost

In terms of cost, EVA hot melt glue has a clear advantage. EVA hot melt glue has a lower production cost and is suitable for large-scale furniture production, while PUR hot melt glue has a higher cost and is usually used for edge sealing of high-end furniture and special products with higher requirements.

Environmental protection

Both hot melt glues meet environmental protection requirements, do not contain solvents and do not release harmful gases. PUR hot melt glue is slightly better than EVA hot melt glue in environmental protection performance because it does not produce too many harmful substances during use and can meet more stringent environmental regulations.

Where Can I Find High-Quality Industrial Hot Melt Glue for Wholesale Purchasing?

Tingjie is a top-tier supplier of industrial hot melt glue, providing wholesale pricing and bulk purchasing options. Our China-based factory ensures stable production and high-quality adhesives for the cabinetry, furniture, and woodworking industries. Whether you need strong bonding solutions, customized adhesive formulations, or fast international shipping, we guarantee reliable supply and competitive prices. Serving global markets in Europe, Vietnam, and the Middle East, Tingjie is the go-to manufacturer for bulk buyers. Request a quote now to secure our latest factory promotions!