The Rise of Laminate Edging: Why These Three Solutions Dominate Today’s Market

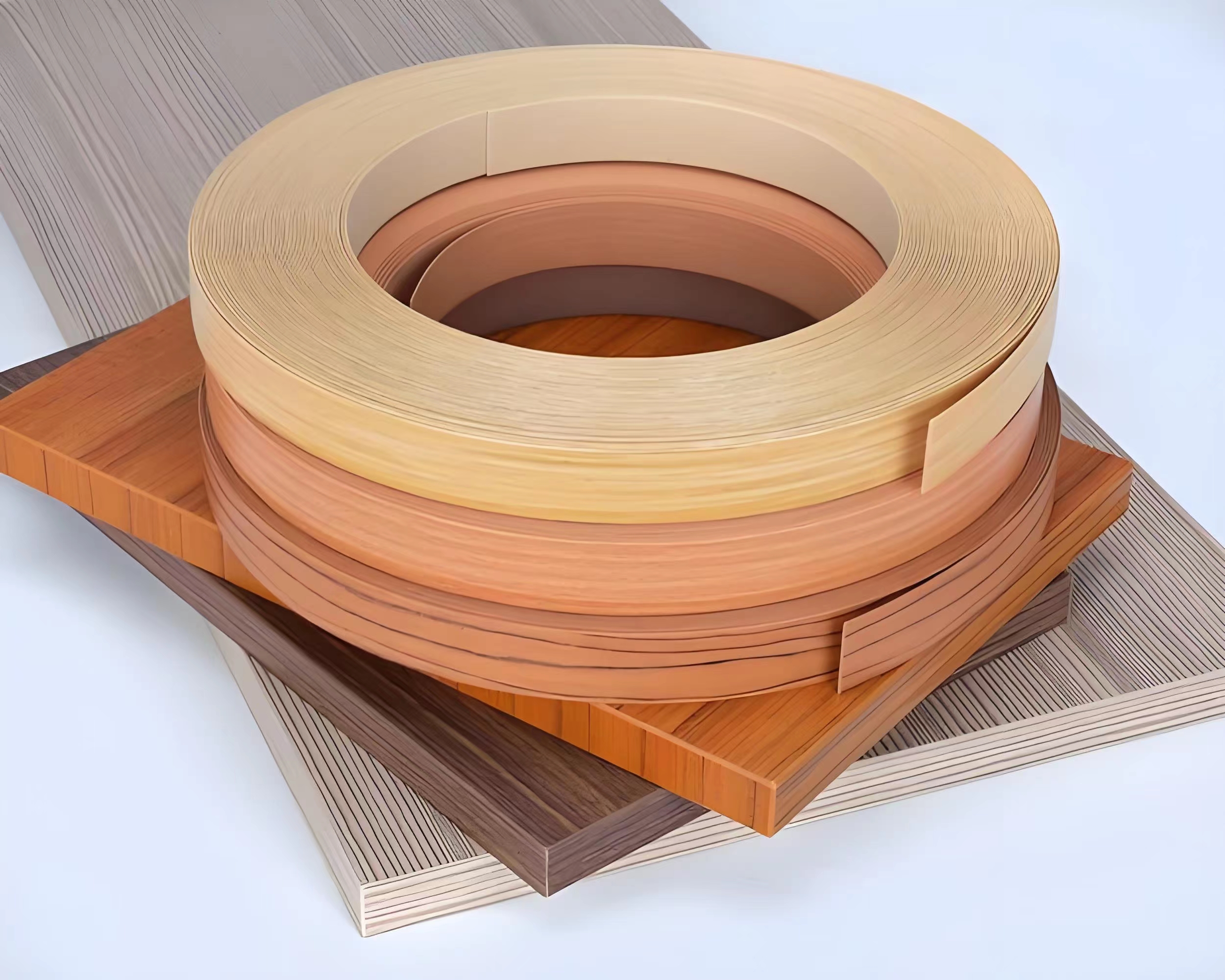

In the fast-paced world of furniture manufacturing and interior design, the importance of clean, durable edges cannot be overstated. Among the top solutions reshaping the industry, three stand out: laminate ABS edging, laminate edge tape, and laminate plywood edge banding. Each brings unique strengths, but together they’re redefining standards for both professionals and DIY enthusiasts. Let’s explore why laminate ABS edging, laminate edge tape, and laminate plywood edge banding are becoming indispensable—and how they’re setting new benchmarks for quality and versatility.

Laminate ABS Edging: Where Durability Meets Design

Laminate ABS edging has emerged as a heavyweight in high-demand settings, from bustling kitchens to busy offices. Crafted by bonding laminate layers to acrylonitrile butadiene styrene (ABS), a robust thermoplastic, laminate ABS edging offers unmatched resistance to impacts, scratches, and daily wear. Unlike traditional materials, which often chip or fade, laminate ABS edging maintains its integrity even after years of use. A 2024 industry study found that furniture finished with laminate ABS edging retained 40% more structural integrity than those using vinyl or wood-based edging, making it a favorite for commercial spaces.

Beyond durability, laminate ABS edging shines in aesthetics. Manufacturers now offer thousands of colorways and textures, from sleek monochromes to realistic wood grains, ensuring laminate ABS edging seamlessly matches cabinetry, desks, and shelving. Leading brands like EdgePro and LaminArt have even introduced custom printing for laminate ABS edging, letting designers add logos or unique patterns—perfect for branding in retail or hospitality settings. This adaptability has made laminate ABS edging a go-to for projects where both form and function matter.

Laminate Edge Tape: Speed and Simplicity Redefined

For quick fixes and small-scale projects, laminate edge tape reigns supreme. This thin, adhesive-backed strip of laminate simplifies edge finishing, requiring no specialized tools—just a roller and utility knife. Whether refinishing a vintage dresser or trimming new shelving,laminate edge tape delivers professional results in minutes. Its popularity among DIYers has surged, with social media tutorials on “laminate edge tape hacks” garnering millions of views.

But laminate edge tape isn’t just for hobbyists. Commercial manufacturers value its efficiency: applying laminate edge tape cuts production time by up to 30% compared to heat-bonded alternatives. New formulations have also improved its performance—waterproof laminate edge tape now withstands kitchen spills, while UV-resistant options hold up in sunlit rooms. With widths ranging from 10mm to 50mm, laminate edge tape adapts to any project, proving that convenience doesn’t mean compromising on quality.

Laminate Plywood Edge Banding: Protecting Plywood’s Potential

Plywood is a staple in construction and furniture, but its exposed edges are vulnerable to moisture and damage. Enter laminate plywood edge banding, which seals these edges while enhancing plywood’s natural appeal. By bonding laminate to plywood edges, this solution prevents delamination, a common issue where plywood layers separate due to humidity. Tests show that plywood treated with laminate plywood edge banding lasts 50% longer in damp environments like bathrooms or basements.

Laminate plywood edge banding also elevates aesthetics. Plywood’s layered look can feel unfinished, but laminate plywood edge banding creates a smooth, cohesive surface. Designers often pair wood-grain laminate plywood edge banding with natural plywood for a rustic-chic vibe, or opt for bold colors to make a statement. For high-end projects, manufacturers offer “invisible” laminate plywood edge banding, where the edging blends so seamlessly with plywood that the joint is nearly undetectable. This attention to detail has made laminate plywood edge banding a favorite for luxury furniture and custom cabinetry.

The Future of Edging: Innovation Across All Three

As demand grows, innovations in laminate ABS edging, laminate edge tape, and laminate plywood edge banding continue apace. Eco-friendly options are on the rise—brands now produce laminate ABS edging and laminate edge tape using recycled materials, while laminate plywood edge banding incorporates plant-based adhesives. Smart technologies are also emerging: some laminate edge tape now features temperature-sensitive adhesives that activate with a simple heat gun, reducing waste from misapplications.

Sustainability is driving another trend: modular systems that combine all three products. For example, a kitchen renovation might use laminate plywood edge banding on cabinet frames, laminate ABS edging on high-impact corners, and laminate edge tape for quick touch-ups. This versatility ensures that laminate ABS edging, laminate edge tape, and laminate plywood edge banding remain essential in a market that values both durability and design.

Conclusion

The edging market is evolving, and laminate ABS edging, laminate edge tape, and laminate plywood edge banding are leading the charge. Each addresses unique needs—laminate ABS edging for toughness, laminate edge tape for speed, and laminate plywood edge banding for plywood protection—yet together, they offer a comprehensive solution for any project. As materials improve and designs expand, these products will only grow more integral to creating furniture and spaces that are both beautiful and built to last. For professionals and DIYers alike, the message is clear: when it comes to edging, laminate ABS edging, laminate edge tape, and laminate plywood edge banding are the future.