In modern furniture manufacturing and woodworking, edge banding is a very important accessory. Edge banding can not only effectively protect the edge of the board from damage, but also improve the overall aesthetics of the furniture. The thickness and material of the edge banding are crucial to the final effect, so choosing the right edge banding thickness has become an important issue that many manufacturers and consumers must face during the purchase process.

Common edge banding thicknesses are 1mm and 2mm, so which one is more suitable for your needs? This article will make a detailed comparison of 1mm edge banding and 2mm edge banding, and discuss their respective characteristics, applicable scenarios, advantages and disadvantages to help you make a wise choice.

What is edge banding?

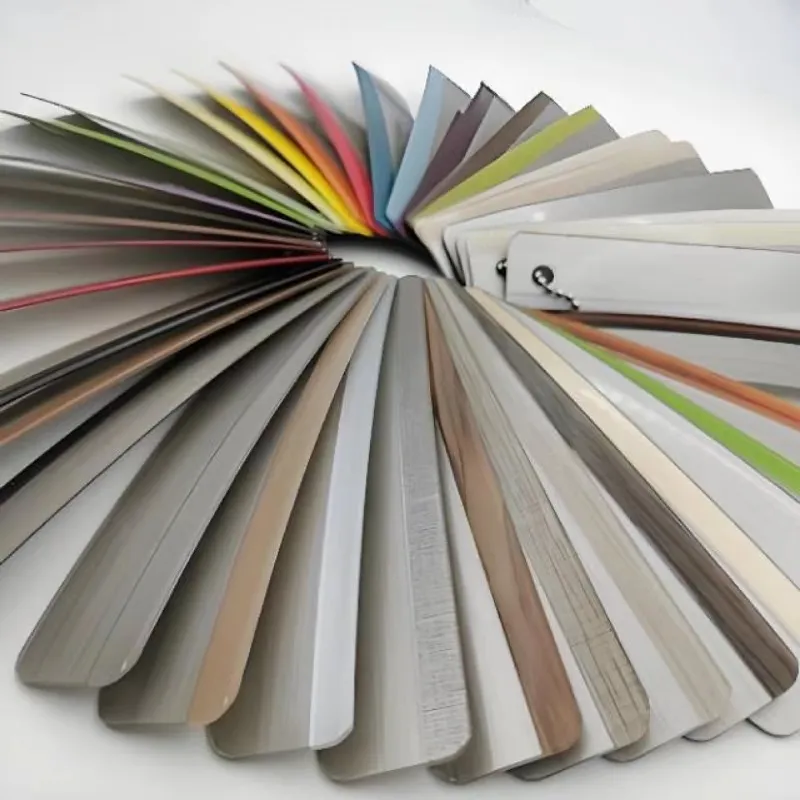

Edge banding is a material used for edge treatment of furniture, cabinets and wooden products. It not only protects the surface of the wood, prevents the intrusion of external factors such as moisture and dust, but also increases the durability and aesthetics of the product. The materials of edge banding usually include PVC, ABS, wood, aluminum alloy, etc., while thickness, color and surface treatment are important factors affecting the selection of edge banding.

According to the use requirements, the thickness of the edge banding can have multiple options, the common ones are 0.4mm, 1mm, 2mm, 3mm, etc. Edge banding of different thicknesses is suitable for different furniture products and working environments. In this article, we will focus on the advantages and disadvantages of the two common edge bandings of 1mm and 2mm.

What are the characteristics of 1mm edge banding?

Characteristics of 1mm edge banding:

1. Lightness and adaptability

2. Flexible installation

3. Relatively low durability

1. Lightness and adaptability

The biggest feature of 1mm edge banding is its thinness, which makes it lighter and easier to install. Due to its thinner structure, 1mm edge banding is usually used for products that do not require high thickness, and can quickly complete the edge banding work.

This thickness of edge banding is widely used for some delicate and lightweight furniture, especially in small spaces or lightweight furniture. For some small furniture, such as bookshelves, display cabinets, etc., 1mm edge banding can effectively ensure beauty without increasing the weight of the product.

2. Flexible installation

Because 1mm edge banding is thinner, it is usually more flexible to install, especially in precision woodworking, and can provide a more delicate appearance. This edge banding is usually fixed with hot melt glue or other adhesives, and the installation process is relatively simple.

When dealing with more delicate furniture or custom furniture, 1mm edge banding performs particularly well. Its thickness is moderate, neither too abrupt nor too complementary to the overall design style. For modern and minimalist home designs, 1mm edge banding can often be perfectly integrated into the design, maintaining a neat and simple appearance.

3. Relatively low durability

Because 1mm edge banding is relatively thin, its durability will be limited to a certain extent. The thickness of the edge banding is closely related to its impact resistance, compression resistance and waterproof performance. Relatively thin edge banding may be more likely to break, fall off or deform when subjected to collision or external force, so it may not be as durable as 2mm edge banding.

What are the applicable scenarios for 1mm edge banding?

1mm edge banding is suitable for the following situations:

● For light furniture or simple furniture that does not require high thickness

● Products that need to be installed quickly and easily

● In the case of limited budget, it is suitable to choose thinner edge banding

● For furniture that is not often subjected to gravity impact or external force damage

What are the characteristics of 2mm edge banding?

The characteristics of 2mm edge banding are:

1. Stronger durability

2. Higher aesthetics and sophistication

3. Relatively complex installation

1. Stronger durability

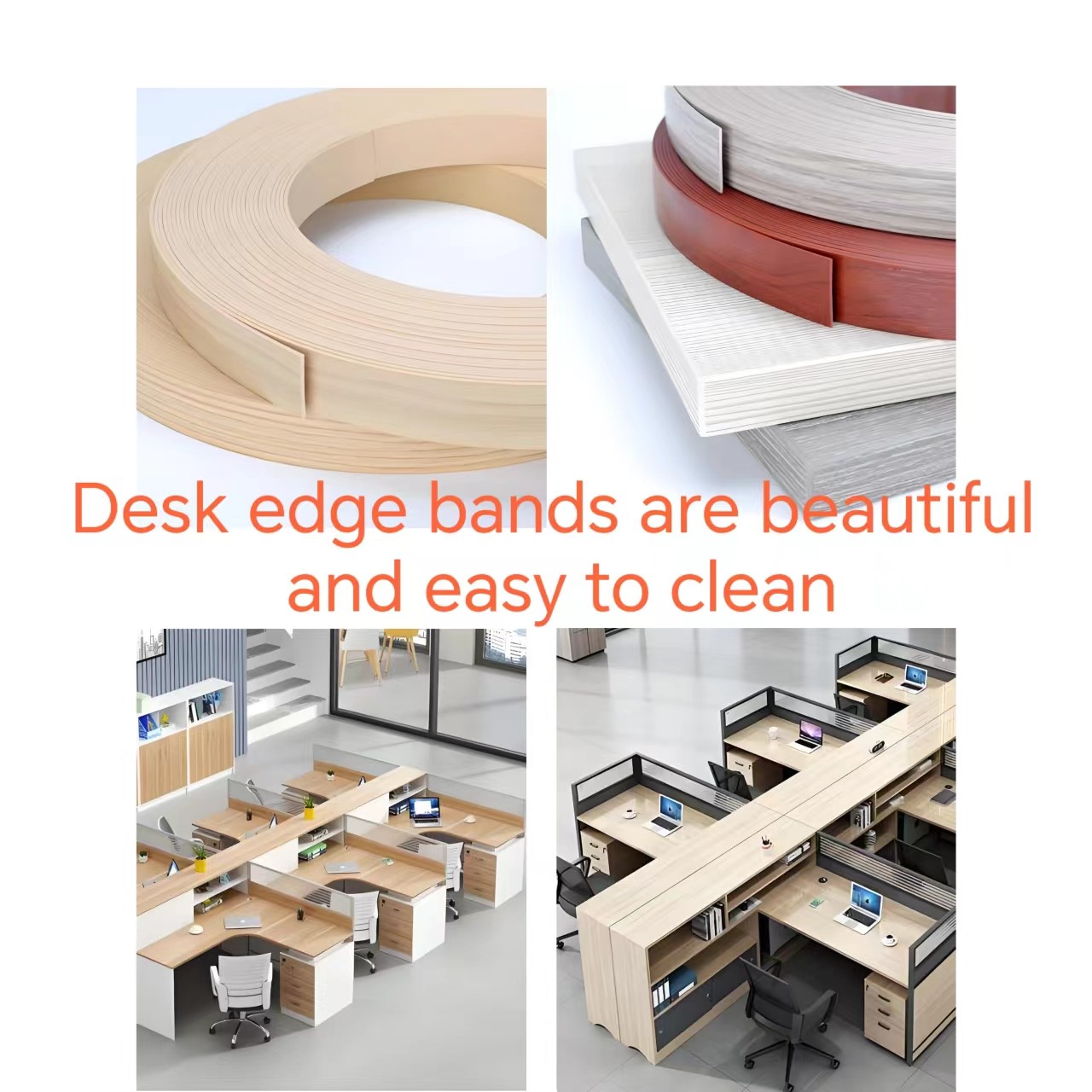

Compared with 1mm edge banding, 2mm edge banding has a higher thickness, which makes it more resistant to impact, wear and water. 2mm edge banding can provide stronger protection, especially for frequently used furniture, load-bearing objects or places that need to be frequently exposed to water and moisture. The advantages of 2mm edge banding are particularly obvious.

Thicker edge banding can effectively avoid wear or scratches on the edges during daily use, especially suitable for heavy furniture, kitchen furniture, bathroom furniture and other scenes that require stronger durability.

2. Higher aesthetics and refinement

Although 2mm edge banding is thicker, it also has its unique aesthetic advantages. Thicker edge banding can make furniture look more refined and classy, especially in traditional or European style furniture, 2mm edge banding can highlight exquisite details and enhance the overall visual effect.

In some high-end custom furniture, 2mm edge banding can bring a more stable and luxurious feeling to the furniture. Moreover, thicker edge banding can visually make the outline of the entire furniture more distinct, making the overall design more three-dimensional.

3. Relatively complex installation

Because 2mm edge banding is thicker, more delicate operation is required during installation, especially in hot-melt edge banding and machine edge banding, temperature control, pressure regulation and other factors need special attention. The complexity and precision requirements of the installation are high, so experienced operators are required to operate.

At the same time, due to the large thickness of the edge banding, it may exert greater pressure on the edges of some furniture. If it is not operated properly, it may cause deformation or other damage to the edge of the furniture.

What are the applicable scenarios for 2mm edge banding?

2mm edge banding is suitable for the following situations:

● Occasions that require high durability and damage resistance of furniture

● High-end custom furniture, traditional style furniture, or furniture that requires a more refined appearance

● High requirements for installation quality, especially when facing complex edge banding requirements

● Furniture environments that require strong wear resistance, moisture resistance, and heat resistance

1mm edge banding and 2mm edge banding: Which is better?

1mm edge banding vs. 2mm edge banding: Durability

2mm edge banding is more durable and can better resist erosion from external factors such as collision, friction, and moisture. In contrast, although 1mm edge banding has a certain degree of durability, its thinner structure makes it more susceptible to damage and aging. Therefore, in scenarios that require higher durability, 2mm edge banding is more suitable.

1mm edge banding vs. 2mm edge banding: aesthetics

1mm edge banding is thinner and suitable for some simple and modern furniture styles, which can provide a clear and simple appearance, while 2mm edge banding is more suitable for high-end and luxurious furniture design, which can create a more refined and three-dimensional effect. From a visual point of view, 2mm edge banding will be thicker and more conspicuous than 1mm edge banding, so for furniture with higher style and design requirements, 2mm edge banding has more advantages.

1mm edge banding vs. 2mm edge banding: installation

1mm edge banding is relatively simple to install and suitable for fast and mass production. However, due to its larger thickness, 2mm edge banding requires more sophisticated process control during installation, and has higher requirements for temperature, pressure, etc., so it is more difficult to install.

1mm edge banding vs. 2mm edge banding: applicable environment

● 1mm edge banding is suitable for light furniture, simple style design and occasions with limited budget.

● 2mm edge banding is suitable for heavy furniture, high-end furniture, traditional style furniture and scenes with high durability requirements.

When choosing between 1mm edge banding and 2mm edge banding, you must choose according to specific needs. If your furniture requires higher durability and a more refined appearance, and the budget and design allow, then 2mm edge banding is undoubtedly a better choice. It can provide stronger protection and durability, and can improve the overall aesthetics in high-end furniture. If you need a quick and simple installation, and the furniture is used in a relatively mild environment, 1mm edge banding is a good choice. It can meet the basic needs of beauty and functionality in daily home life, and the cost is relatively low.

Tingjie Decoration Materials Co., Ltd. – Leading Manufacturer of Edge Banding

Dongguan Tingjie Decoration Materials Co., Ltd. is a premier manufacturer of high-quality edge banding materials, including PVC, ABS, and wood grain edge banding strips. With a production capacity of over 10,000 tons annually, we supply wholesale orders at competitive prices. Our T-type and U-type profiles cater to diverse industry needs, and we offer customization to ensure your specific requirements are met. As a trusted supplier based in Dongguan, China, we offer flexible quotes, promotions, and bulk discounts for businesses worldwide.