3D Edge Banding Revolutionizes Furniture Design

Acrylic Edge Banding, Acrylic Edge Banding Tape, and 3D Edge Banding Lead the Way in Furniture and Cabinetry Trends.In the ever-evolving world of furniture manufacturing and interior design, acrylic edge banding, acrylic edge banding tape, and 3D edge banding are making headlines as the materials of choice for modern, durable, and visually appealing finishes. Industry experts report that these products are rapidly replacing traditional PVC and  melamine options due to their superior performance, aesthetics, and environmental benefits.

melamine options due to their superior performance, aesthetics, and environmental benefits.

The Rise of Acrylic Edge Banding

Acrylic edge banding has become synonymous with premium quality in the furniture sector. Made from high-grade acrylic resins, it offers exceptional resistance to scratches, impacts, and UV light, ensuring that furniture edges remain intact and attractive for years. Unlike conventional edge banding materials, acrylic variants do not yellow over time, making them ideal for both residential and commercial applications.

Manufacturers are particularly impressed with the seamless finish that acrylic edge banding provides. When properly applied, it creates an almost invisible bond between the panel and the edge, giving furniture a high-end, custom look. This has made it a favorite among luxury furniture brands and high-end kitchen designers.

The Convenience of Acrylic Edge Banding Tape

While traditional acrylic edge banding requires professional application with specialized machinery, acrylic edge banding tape has opened the market to DIY enthusiasts and small-scale manufacturers. This self-adhesive version offers the same durability and aesthetic appeal as standard acrylic edge banding but can be applied with simple tools.

The versatility of acrylic edge banding tape has contributed to its growing popularity. Available in a wide range of colors and finishes, including matte, glossy, and textured, it allows for greater design flexibility. Interior designers are now using this product to create bold color contrasts and unique design elements in furniture pieces.

The Innovation of 3D Edge Banding

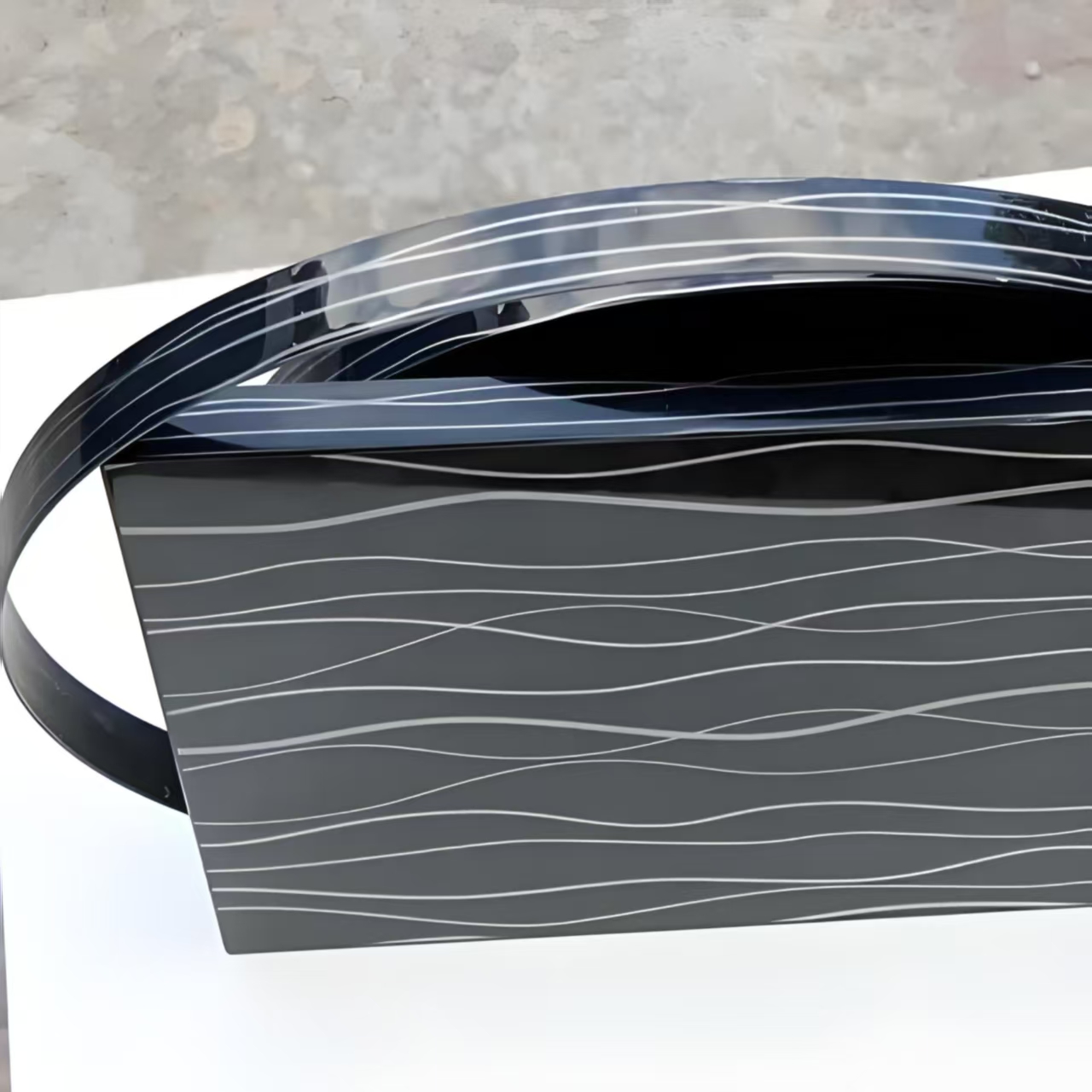

Taking design possibilities to the next level, 3D edge banding has introduced a new dimension to furniture aesthetics. This innovative product features embossed patterns that mimic natural materials like wood grain, stone, or leather. When applied to furniture edges, it creates a realistic, three-dimensional effect that enhances the overall appearance of the piece.

3D edge banding is not just about looks; it also offers enhanced durability. The embossed patterns are resistant to wear and tear, maintaining their appearance even with heavy use. This makes the product particularly suitable for high-traffic commercial spaces like hotels, restaurants, and offices.

Market Trends and Growth Factors

Industry analysts predict strong growth for the acrylic edge banding, acrylic edge banding tape, and 3D edge banding markets in the coming years. Several factors are driving this growth:

1. Increased demand for premium furniture - As consumers become more design-conscious, there is a growing preference for furniture with high-quality finishes.

2. Advancements in manufacturing technology - New production techniques have made these products more affordable and accessible.

3. Growing environmental awareness - Acrylic edge banding products are more eco-friendly than traditional options, appealing to environmentally conscious consumers.

Sustainability and Environmental Impact

One of the most significant advantages of acrylic edge banding, acrylic edge banding tape, and 3D edge banding is their environmental profile. Unlike PVC edge banding, which contains harmful chemicals, acrylic products are free from toxic substances and can be recycled. This has made them a popular choice among manufacturers looking to reduce their environmental footprint.

Additionally, the durability of these products means that furniture lasts longer, reducing the need for replacement and ultimately lowering waste. This aligns with the growing circular economy principles being adopted across various industries.

Technological Advancements

The edge banding industry is experiencing rapid technological advancements that are improving product quality and expanding design possibilities. Digital printing technology, for instance, has allowed manufacturers to create acrylic edge banding with incredibly realistic wood grain patterns. Similarly, advancements in extrusion technology have resulted in 3D edge banding products with more intricate designs and better texture definition.

These technological improvements are not limited to aesthetics. Manufacturers are also developing acrylic edge banding tape with improved adhesive properties, ensuring a stronger bond and longer-lasting finish. Some innovative products even feature heat-activated adhesives that create a bond stronger than traditional glue.

Applications Beyond Furniture

While furniture manufacturing remains the primary application for acrylic edge banding, acrylic edge banding tape, and 3D edge banding, these products are finding new uses in various industries:

- Interior design - Used to create decorative wall panels and room dividers

- Retail displays - Enhancing the appearance of store fixtures and product displays

- Automotive industry - Applied to interior panels for a premium finish

- Healthcare facilities - Used in medical cabinets and equipment due to hygienic properties

The Future of Edge Banding

As design trends continue to evolve, the future looks bright for acrylic edge banding, acrylic edge banding tape, and 3D edge banding. Industry experts anticipate several developments:

1. Smart edge banding - Incorporating technology like LED lighting or touch sensors

2. Customization - On-demand production of unique designs through digital printing

3. Enhanced sustainability - Development of bio-based acrylic materials

4. Improved performance - Products with even greater resistance to heat, chemicals, and wear

Conclusion

The edge banding industry is undergoing a transformation, driven by consumer demand for high-quality, durable, and aesthetically pleasing furniture finishes. Acrylic edge banding, acrylic edge banding tape, and 3D edge banding are at the forefront of this revolution, offering superior performance, design versatility, and environmental benefits.

As technology continues to advance and consumer preferences evolve, these products are poised to become even more integral to furniture manufacturing and interior design. The future of edge banding is not just about protecting furniture edges; it's about creating design statements that enhance spaces and elevate the overall aesthetic experience.

For manufacturers, designers, and consumers alike, the message is clear: when it comes to edge banding, acrylic edge banding, acrylic edge banding tape, and 3D edge banding are setting the standard for quality, innovation, and style in the modern furniture industry.