In the industrial manufacturing and packaging industries, hot melt adhesives are widely used in furniture manufacturing, automotive industry, electronic packaging, book binding and other fields as an efficient and environmentally friendly adhesive. In the classification of hot melt adhesives, EVA hot glue and PUR hot glue are the two most common types of hot melt adhesives.

Although they are both hot melt adhesives, there are significant differences in chemical composition, bonding characteristics, usage and weather resistance. This article will conduct an in-depth analysis of the differences between these two hot melt adhesives to help readers better understand and choose the right hot melt adhesive products.

EVA hot glue and PUR hot glue: What are they?

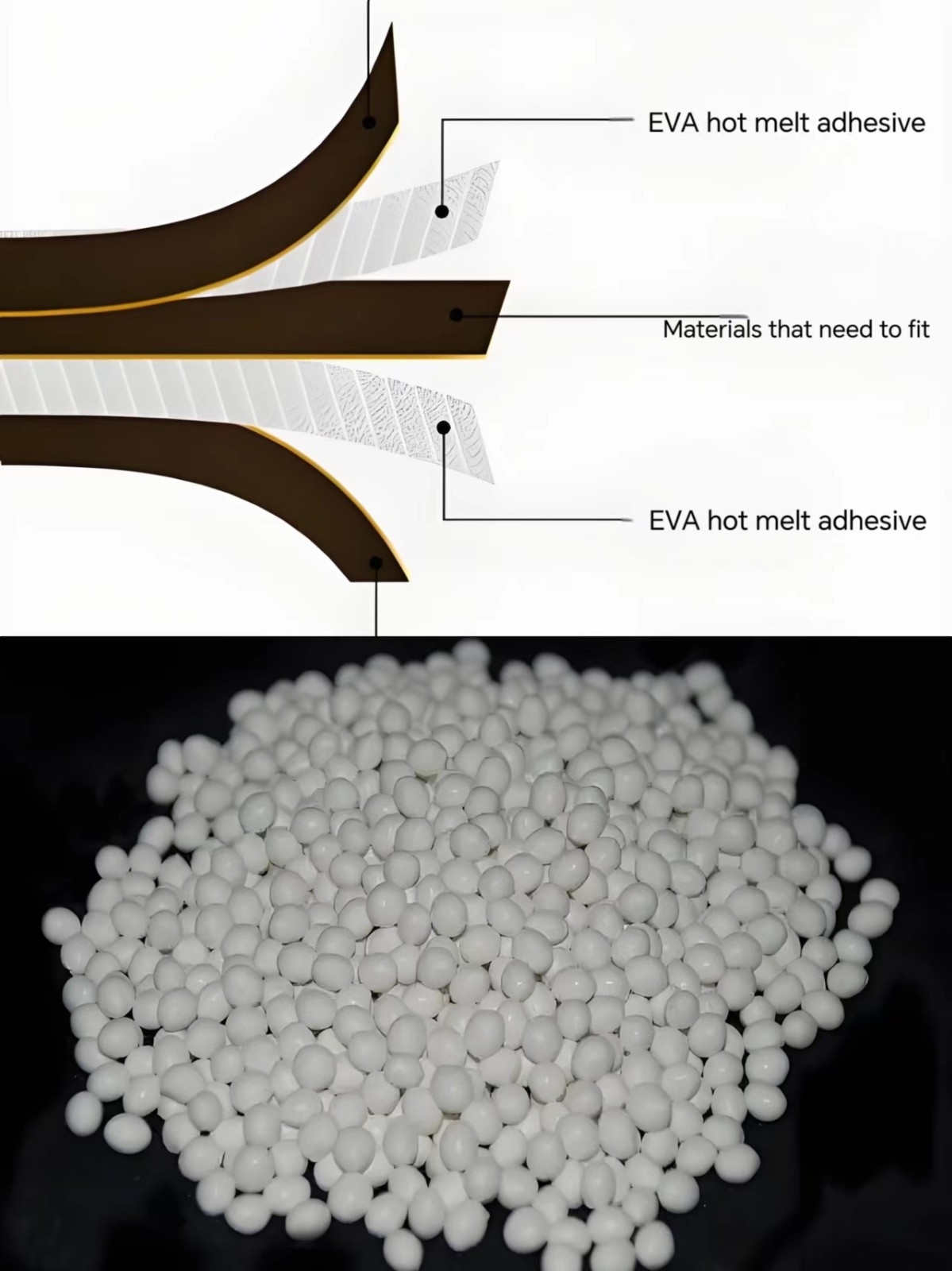

EVA hot glue

EVA (Ethylene Vinyl Acetate, ethylene-vinyl acetate copolymer) hot melt adhesive is based on EVA resin and is formulated with other ingredients such as plasticizers, stabilizers and fillers. The main component of this hot melt adhesive is a copolymer of ethylene and vinyl acetate. The molecular structure of EVA resin is composed of ethylene monomer and vinyl acetate monomer. The addition of vinyl acetate makes EVA resin have better bonding properties. The main features of EVA hot glue are:

● Fast curing speed: After heating and melting, EVA hot glue can be quickly cured by cooling without additional chemical reaction.

● Easy operation: It can be applied by hot melt adhesive gun, coating machine or other equipment, suitable for automated production.

● Relatively low cost: Since the production process of EVA hot glue is relatively mature and the cost of raw materials is low, it has economic advantages in large-scale applications.

EVA hot glue is widely used in book binding, packaging industry, woodworking splicing, footwear manufacturing and other fields, especially for application scenarios with low requirements for bonding strength.

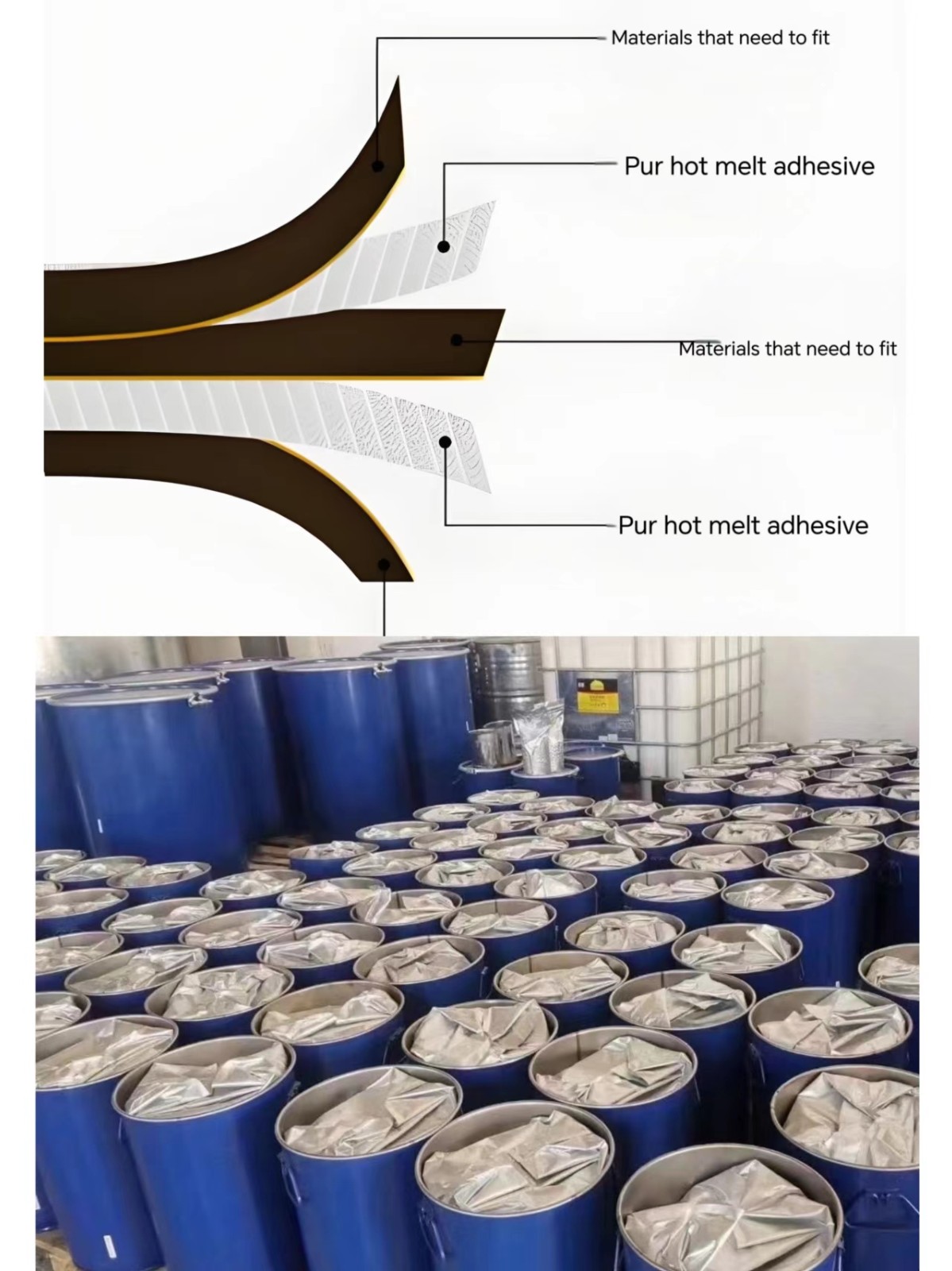

PUR hot glue

PUR (Polyurethane Reactive) hot melt adhesive is a more advanced type of hot melt adhesive. After heating and melting, it not only relies on physical cooling to solidify, but also reacts chemically with moisture in the air or moisture on the surface of the substrate to form a cross-linked structure, making the bonding performance more stable. The main features of PUR hot glue include:

● Super strong bonding strength: Since PUR hot glue forms a chemical cross-linking structure after curing, it has extremely high bonding strength and is suitable for high-demand industrial applications.

● Excellent weather resistance: PUR hot glue has strong resistance to moisture and heat, chemicals and aging, and is not easily invalidated due to environmental changes.

● Long open time: PUR hot melt adhesive has a certain operating time before it is fully cured, which is suitable for application scenarios that require precise adjustment.

PUR hot glue is often used in high-end manufacturing industries such as woodworking furniture edge banding, automotive parts bonding, and electronic product assembly. It is more suitable for application fields with high requirements for bonding effect and durability.

EVA hot glue and PUR hot glue: What is the difference?

Although EVA hot glue and PUR hot glue belong to the same hot melt adhesive system, there are obvious differences between the two in terms of chemical composition, bonding performance, weather resistance, and usage. The following is an analysis of the main differences between the two hot melt adhesives, EVA hot glue and PUR hot glue.

EVA hot glue vs. PUR hot glue: 5 major differences

1. Differences in chemical composition and curing mechanism

2. Differences in bonding strength and flexibility

3. Differences in weather resistance and durability

4. Differences in construction methods and equipment requirements

5. Differences in storage and stability

● Differences in chemical composition and curing mechanism: The main components of EVA hot glue are EVA resin and tackifier, which are thermoplastic polymers, that is, it becomes liquid after being heated and melted, and re-solidifies after cooling, but does not undergo chemical reactions. Therefore, EVA hot glue can be heated, melted and cooled multiple times, and is a reversible bond.

The main component of PUR hot glue is polyurethane prepolymer, which, in addition to physical cooling and curing, also undergoes chemical cross-linking reactions, making its bonding effect stronger and irreversible after curing. The polyurethane chain structure formed after PUR hot glue is cured gives it higher mechanical properties and weather resistance.

● Differences in bonding strength and flexibility: EVA hot glue has relatively low bonding strength and is suitable for light load or short-term bonding applications. Since EVA is a thermoplastic material, it may soften in high temperature environments, resulting in a decrease in bonding performance.

PUR hot glue, however, forms a more stable polyurethane cross-linked structure due to chemical reactions, and its bonding strength is much higher than that of EVA hot glue. PUR hot melt adhesive performs better, especially in applications that need to withstand greater stress, temperature changes or humid environments. In addition, PUR hot glue has better flexibility and can withstand certain deformation without affecting the bonding effect.

● Difference between weather resistance and durability: EVA hot glue has relatively poor weather resistance, especially in high temperature, high humidity or low temperature environments, and is prone to bonding failure. For example, in hot weather, the material bonded by EVA hot glue may loosen, while in low temperature environments, the glue layer may become brittle.

PUR hot glue has significantly better weather resistance than EVA hot glue. It can resist moisture, chemical erosion, ultraviolet rays and temperature changes, so it is suitable for applications that require long-term stable bonding, such as automotive manufacturing and outdoor equipment bonding.

● Difference between construction method and equipment requirements: EVA hot glue is usually applied using hot melt adhesive gun, coating machine or roller coating equipment. The equipment is relatively simple and easy to operate, which is suitable for mass production lines. Since EVA hot glue can be repeatedly heated and melted, the operation error during the construction process is easier to correct.

PUR hot glue has higher construction requirements. It usually requires a special PUR hot glue machine for heating and gluing, and it takes a certain amount of time for chemical curing after gluing, so the construction complexity and equipment cost are high. In addition, once PUR hot glue is cured, it is almost impossible to re-melt or adjust, so the construction requires high precision.

● Difference between storage and stability: EVA hot glue has relatively loose storage conditions. Generally, it only needs to be protected from light, moisture and high temperature. Since it does not react chemically, it has a long shelf life, usually up to two years or more.

PUR hot glue reacts with moisture in the air, so it has stricter requirements for the storage environment. It usually needs to be sealed and used within a certain period of time, otherwise it will solidify and deteriorate due to moisture absorption.

Through the above comparison, we know that EVA hot glue occupies an important position in packaging, book binding, woodworking and other fields due to its low cost, convenient operation and suitability for mass production. However, due to its limited bonding strength and weather resistance, it is not suitable for high-demand applications.

PUR hot glue has outstanding performance in the field of high-end manufacturing due to its super strong bonding force, excellent weather resistance and durability, and is suitable for industries such as automobiles, electronics, and furniture that have higher requirements for bonding performance. However, the use cost of PUR hot glue is higher, the construction requirements are more stringent, and the storage conditions are also more demanding.

Affordable Edge Banding Solutions from Tingjie

Dongguan Tingjie Decoration Materials Co., Ltd. provides cost-effective edge banding products without compromising quality. As a China-based manufacturer, we specialize in EVA hot glue, PUR hot melt adhesive, and wood grain edge banding strips, offering a variety of profiles including T-type and U-type. Whether you’re looking for bulk quantities or customized solutions, we supply high-quality products at wholesale prices and offer attractive discounts for large orders. Get in touch today for personalized quotes and take advantage of our competitive prices on edge banding materials.