Discover the Power of EVA Industrial Hot Melt Adhesive for Your Business

In today's fast-paced industrial landscape, finding the right adhesive solution is crucial for efficiency, durability, and cost-effectiveness. Whether you're involved in manufacturing, packaging, automotive or, any other industry, the need for a reliable and versatile adhesive is ever-present. That's where EVA industrial hot melt adhesive, commonly known as EVA hot melt adhesive or simply industrial hot melt adhesive, comes into play. This remarkable product, often referred to as hot glue adhesive, has revolutionized the way industries bond materials together. In this article, we will explore the numerous benefits, applications, and reasons E whyVA industrial hot melt adhesive is the ultimate choice for your business.

Understanding EVA Industrial Hot Melt Adhesive

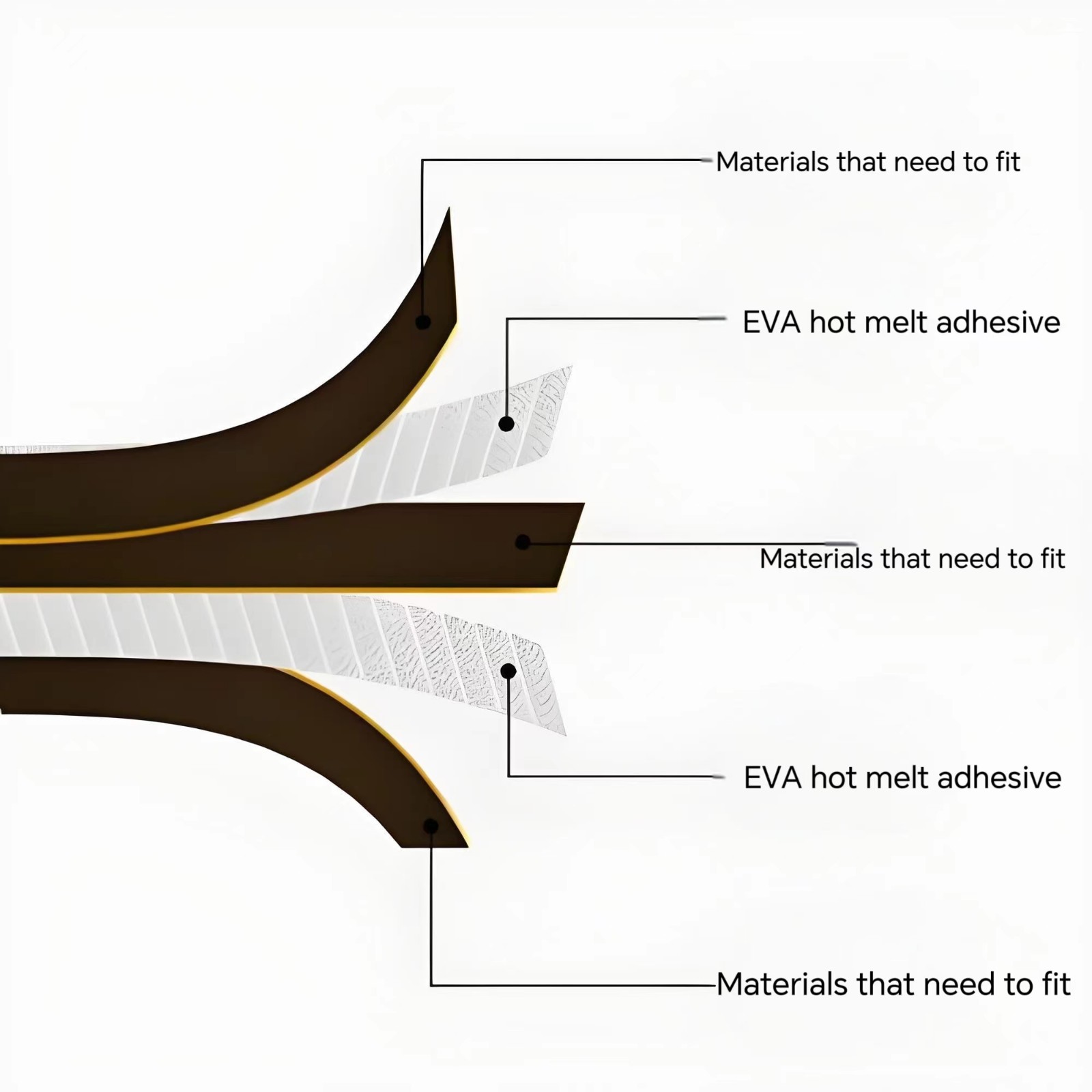

EVA industrial hot melt adhesive is a type of thermoplastic adhesive that is widely used across various sectors due to its exceptional bonding properties. The term "EVA" stands for Ethylene-Vinyl Acetate, which is the primary polymer used in its formulation. This adhesive is designed to provide strong, durable, and flexible bonds, making it ideal for a wide range of applications. Unlike traditional adhesives that require solvents or curing times, EVA hot melt adhesive offers instant bonding capabilities, significantly speeding up production processes.

The versatility of industrial hot melt adhesive is one of its most notable features. It can bond a variety of materials, including plastics, metals, wood, and fabrics. This makes it a go-to solution for manufacturers who need a single adhesive to handle multiple tasks. Whether you're assembling electronic components, packaging products, or constructing furniture, EVA industrial hot melt adhesive can meet your needs.

The Benefits of EVA Industrial Hot Melt Adhesive

Fast Bonding and Increased Efficiency

One of the primary advantages of EVA industrial hot melt adhesive is its rapid bonding capability. Unlike other adhesives that may take hours or even days to cure, EVA hot melt adhesive forms a strong bond almost instantly. This means that production lines can run more smoothly, with fewer delays and increased output. For businesses looking to maximize efficiency and meet tight deadlines, the speed of EVA hot melt adhesive is invaluable.

Strong and Durable Bonds

Despite its quick bonding time, EVA industrial hot melt adhesive does not compromise on strength. It provides robust and long-lasting bonds that can withstand various environmental conditions, including temperature fluctuations, moisture, and mechanical stress. This durability ensures that your products remain intact throughout their lifecycle, reducing the risk of defects and returns. Whether you're bonding heavy components in the automotive industry or creating durable packaging, EVA hot melt adhesive can handle the job.

Versatility in Applications

The wide range of materials that EVA hot melt adhesive can bond makes it a versatile solution for numerous industries. From automotive and electronics to packaging and furniture, this adhesive can be used in a variety of applications. For example, in the automotive industry, EVA industrial hot melt adhesive is used to bond interior components, such as dashboards and upholstery. In packaging, it is used to seal boxes and attach labels. Its ability to bond dissimilar materials also makes it ideal for composite structures, where different materials need to be joined together seamlessly.

Cost-Effective Solution

When it comes to cost, EVA industrial hot melt adhesive offers significant advantages. Its fast bonding time reduces labor costs, as workers can complete tasks more quickly. Additionally, because it is a thermoplastic adhesive, it can be reheated and reused if necessary, minimizing waste. This makes EVA hot melt adhesive a cost-effective choice for businesses looking to optimize their production processes without sacrificing quality.

Environmentally Friendly

In an era where sustainability is a top priority, EVA industrial hot melt adhesive stands out as an environmentally friendly option. Unlike solvent-based adhesives, which can release harmful volatile organic compounds (VOCs) into the air, E hotVA melt adhesive is free of solvents. This makes it safer for workers and the environment. Additionally, its ability to be reused and recycled further reduces its environmental impact.

Applications of EVA Industrial Hot Melt Adhesive

Packaging Industry

In the packaging sector, EVA hot melt adhesive is a game-changer. It is used to seal cardboard boxes, attach labels, and bond various packaging components. Its fast bonding time ensures that packaging lines can operate at maximum efficiency, reducing downtime and increasing productivity. The strong and flexible bonds provided by EVA hot melt adhesive also ensure that packages remain secure during transportation, reducing the risk of damage and returns.

Automotive Industry

The automotive industry relies heavily onVA E industrial hot melt adhesive for various applications. It is used to bond interior components, such as dashboards, door panels, and upholstery. The adhesive's ability to withstand high temperatures and mechanical stress makes it ideal for this demanding environment. Additionally, EVA hot melt adhesive is used in the assembly of exterior components, such as bumpers and body panels, providing strong and durable bonds that can withstand the rigors of daily use.

Electronics Industry

In the electronics sector, precision and reliability are crucial. EVA hot melt adhesive is used to bond electronic components, such as circuit boards and connectors. Its ability to provide strong and flexible bonds ensures that these components remain securely in place, even under the stress of repeated use. Additionally, EVA hot melt adhesive's resistance to moisture and temperature fluctuations makes it ideal for electronic applications where reliability is paramount.

Furniture Industry

The furniture industry also benefits greatly from EVA industrial hot melt adhesive. It is used to bond wooden components, attach upholstery, and secure hardware. The adhesive's flexibility allows it to withstand the movement and stress of everyday use, ensuring that furniture remains durable and long-lasting. Whether you're manufacturing chairs, tables, or cabinets, EVA hot melt adhesive can provide the strong and reliable bonds you need.

Choosing the Right EVA Industrial Hot Melt Adhesive

With so many options available in the market, selecting the right EVA industrial hot melt adhesive for your needs specific is essential. Here are a few factors to consider:

Bonding Requirements

Different applications require different bonding strengths and properties. Consider the materials you need to bond and the environmental conditions your product will face. For example, you if're bonding components that will be exposed to high temperatures, you'll need an EVA hot melt adhesive specifically designed for thermal resistance.

Application Method

EVA industrial hot melt adhesive is available in various forms, including sticks, pellets, and cartridges. The application method you choose will depend on your production process and equipment. For example, if you have a high-speed packaging line, a hot melt adhesive applicator designed for continuous operation be may the best choice.

Open Time and Set Time

Open time refers to the amount of time you have to position the components before the adhesive starts to bond. Set time refers to the time it takes for the adhesive to form a strong bond. Depending on your production process, you may need an adhesive with a longer or shorter open time and set time. For example, if you're bonding large components that require precise positioning, a longer open time may be beneficial.

Safety and Compliance

Ensure that the EVA hot melt adhesive you choose meets all relevant safety and regulatory standards. Look for products that are free of harmful substances and comply with industry regulations. This is especially important if your products are intended for use in sensitive environments, such as food packaging or medical devices.

Conclusion

EVA industrial hot melt adhesive, also known E asVA hot melt adhesive or industrial hot melt adhesive, is a versatile and reliable adhesive solution that offers numerous benefits for businesses across various industries. Its fast bonding time, strong and durable bonds, versatility in applications, cost-effectiveness, and environmental friendliness make it an ideal choice for modern industrial processes. Whether you're in the packaging, automotive, electronics, or furniture industry, EVA hot melt adhesive can help you improve efficiency, reduce, costs and enhance the quality of your products.

By carefully selecting the right EVA industrial hot melt adhesive for your specific needs, you can unlock its full potential and take your business to new heights. Invest in the power of EVA hot melt adhesive today and experience the difference it can make in your production processes.