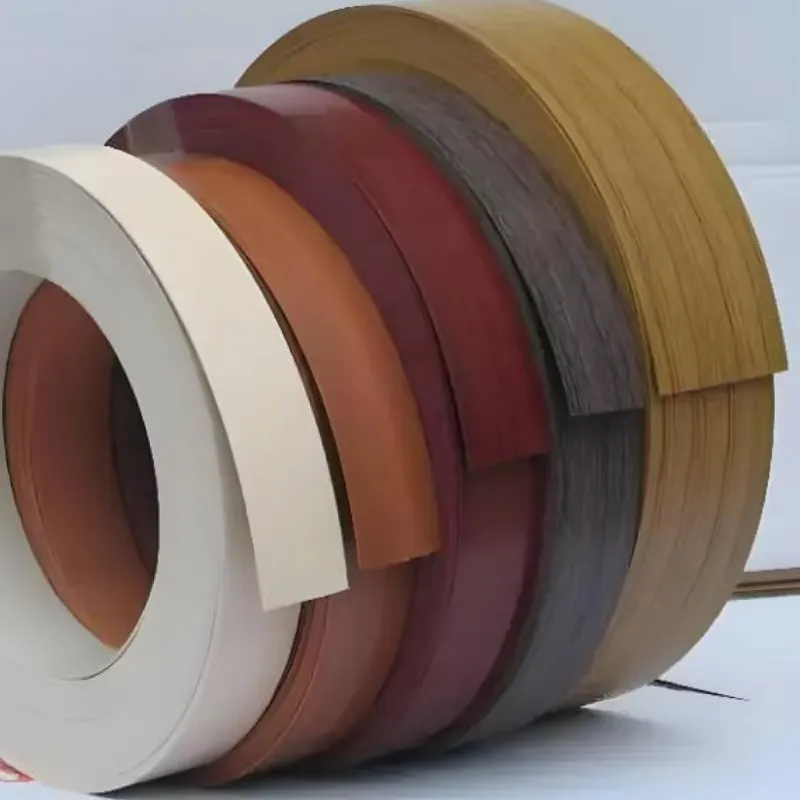

As an important component in furniture manufacturing and decoration, edge banding has the main function of sealing the edges of furniture boards to prevent them from being damaged by external factors such as moisture, dust, stains, etc., while improving the aesthetics of furniture. There are many types of edge banding materials, among which plastic edge banding such as PVC and ABS are the most common.

The thickness of edge banding is one of the important factors affecting its quality and application effect. The common thickness is 3mm and 1mm. This article will deeply explore the difference between 3mm edge banding and 1mm edge banding from multiple dimensions to help consumers and manufacturers make the most suitable choice.

What is edge banding?

Edge banding is a decorative and protective material used for the edges of furniture boards. It is widely used in edge processing of materials such as medium-density fiberboard (MDF), particleboard, and solid wood board. The role of edge banding is not limited to protecting the edges of boards from physical wear, but also preventing external factors such as moisture and dust from damaging furniture. In addition, edge banding can enhance the appearance of furniture and make it more refined and beautiful.

The material and thickness of edge banding will directly affect its use effect. Different thicknesses are suitable for different furniture types and usage scenarios, and the choice of thickness is usually closely related to the thickness of the board, the style of the furniture, and the needs of consumers.

What are the characteristics of 3mm edge banding?

3mm edge banding is a common edge banding thickness, which is usually used in furniture with thicker boards, especially in most furniture production. 3mm edge banding not only has higher physical strength, but also provides better protection.

What are the advantages of 3mm edge banding?

Advantages of 3mm edge banding:

1. Provide stronger edge protection

2. Higher durability

3. Good sealing

4. Significant visual effect

1. Provide stronger edge protection

The thicker design of 3mm edge banding enables it to provide stronger protection for the edges of furniture. Especially in daily use such as collision and friction, 3mm edge banding can more effectively prevent damage to the board and avoid cracking or warping of the edge part.

2. Higher durability

Compared with 1mm edge banding, 3mm edge banding is usually more durable. Its thickness makes its impact and scratch resistance more prominent, which can effectively extend the service life of furniture. In addition, 3mm edge banding has good durability and is not prone to aging phenomena such as deformation and cracking.

3. Good sealing

3mm edge banding is usually fixed with hot melt adhesive or other adhesive materials. Due to its large thickness, 3mm edge banding can form a stronger seal to prevent moisture or air from penetrating into the edge of the board, thereby reducing problems such as board expansion and deformation, and is especially suitable for humid environments such as kitchens and bathrooms.

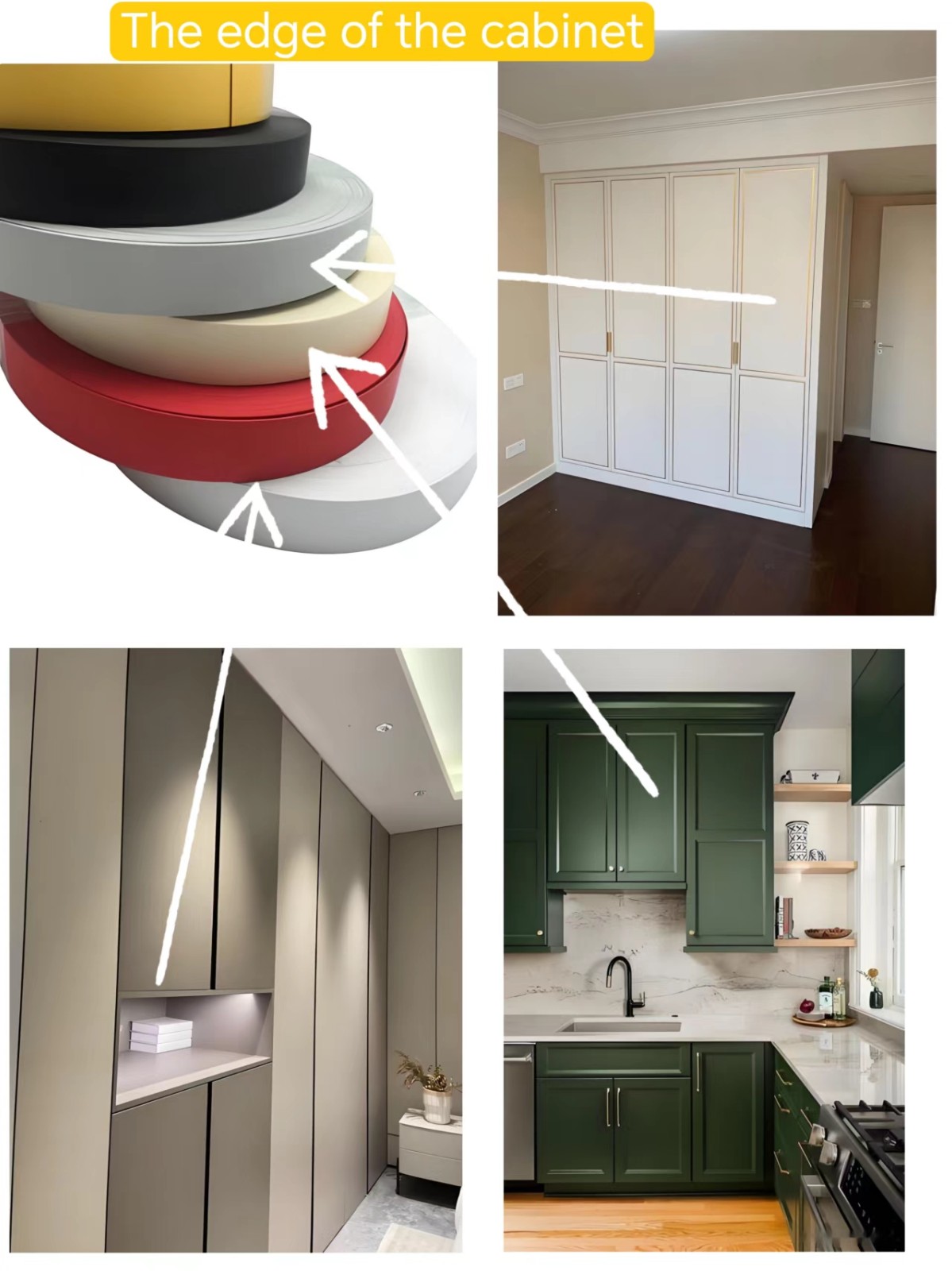

4. Significant visual effect

Thicker edge banding is usually more conspicuous in visual effect and can bring more significant decorative effects to furniture. 3mm edge banding is suitable for furniture that pursues a grand and exquisite appearance, which can effectively enhance the overall beauty of the furniture.

What are the disadvantages of 3mm edge banding?

The disadvantages of 3mm edge banding are:

1. Higher production cost

2. More complicated installation

1. Higher production cost

Due to the thicker thickness and higher production cost of 3mm edge banding, its price is usually more expensive than 1mm edge banding. This may increase the production and purchase costs for some small furniture manufacturers or cost-sensitive consumers.

2. More complicated installation

Due to its thickness, 3mm edge banding may require more time and process processing during installation. Especially for some furniture with complex designs or special shapes, the installation of 3mm edge banding may require more delicate processes.

What are the characteristics of 1mm edge banding?

As a thinner edge banding, the main characteristics of 1mm edge banding are lightness and flexibility, which are suitable for some furniture types that require lower edge banding thickness. Despite its thin thickness, 1mm edge banding can also provide sufficient edge protection in many cases.

What are the advantages of 1mm edge banding?

The advantages of 1mm edge banding are:

1. Applicable to thin boards

2. Low cost

3. Easy to install

4. Better adaptability

1. Applicable to thin boards

One of the biggest advantages of 1mm edge banding is that it is suitable for edge banding of thin boards. For some thin board furniture, 1mm edge banding can better match the thickness of the board, maintain the edge banding effect without being too abrupt, and the overall visual effect is more coordinated.

2. Low cost

Compared with 3mm edge banding, 1mm edge banding has a lower production cost, so its price is usually more affordable. In the case of tight budget or large-scale purchase, 1mm edge banding is a more economical choice.

3. Easy installation

1mm edge banding is easier to install due to its thin thickness. Whether it is hot melt adhesive bonding or pressing process, the operation of 1mm edge banding is relatively simple, which can improve production efficiency and reduce labor costs.

4. Better adaptability

Because 1mm edge banding is thinner, it has strong applicability, especially for some furniture products that do not require a heavy appearance. 1mm edge banding can be better integrated into the overall design of furniture and adapt to the needs of various styles of homes.

What are the disadvantages of 1mm edge banding?

The disadvantages of 1mm edge banding are:

1. Lower protection ability

2. Poor sealing

3. Weak visual effect

1. Lower protection ability

Compared with 3mm edge banding, the protection performance of 1mm edge banding is relatively weak. Due to its thin thickness, 1mm edge banding has poor ability to resist external force collision, friction and scratching, and is prone to wear or deformation, especially in some high-frequency use environments, its durability is low.

2. Poor sealing

Due to its thin thickness, 1mm edge banding has weaker performance in waterproofing and moisture-proofing. Although it can provide basic edge protection for furniture, it cannot effectively prevent moisture penetration or air intrusion like 3mm edge banding. Therefore, 1mm edge banding is not suitable for environments with heavy humidity.

3. Weak visual effect

Due to its thin thickness, the decorative effect of 1mm edge banding is relatively weak, and it may not add too many visual highlights to the furniture. For some furniture that pursues high-end and atmospheric design, 1mm edge banding may not be prominent enough.

Comparison between 3mm edge banding and 1mm edge banding

When choosing edge banding, 3mm edge banding and 1mm edge banding have their own advantages and disadvantages, and consumers and manufacturers need to choose according to actual needs. The following is a detailed comparison between 3mm edge banding and 1mm edge banding:

| Features | 3mm edge banding | 1mm edge banding |

| Protection | Strong, better able to resist external forces and physical damage | Weak, prone to wear and deformation |

| Durability | Higher, able to withstand long-term use | Low, relatively short service life |

| Applicable board thickness | Suitable for thicker panels | Suitable for thin panels and can be matched with them |

| Cost | Higher, higher production costs | Low, more economical production cost |

| Installation difficulty | More complex to install, requires more processing | Easy to install and operate |

| Aesthetics | Stronger visual effects, suitable for atmospheric and exquisite designs | Weak visual effect, more suitable for simple design |

| Waterproof and moisture-proof | Stronger, suitable for humid environments | Weak, suitable for dry environment |

3mm edge banding and 1mm edge banding each have their own unique advantages and scope of application. When choosing edge banding, consumers should decide according to actual needs. For example, for large-sized, thick-board furniture, or furniture that requires stronger protection and durability, 3mm edge banding is an ideal choice; while for thin-board furniture, limited budgets, or furniture with lower requirements for appearance, 1mm edge banding is more economical.

How Can Furniture Manufacturers Benefit from Tingjie’s Edge Banding?

Tingjie supplies ABS and PVC edge banding designed for furniture factories, wholesalers, and distributors. Our products are available in custom sizes, finishes, and colors, making them suitable for various furniture applications. With low prices, wholesale purchasing options, and factory-direct supply, we help businesses reduce costs while maintaining premium quality. We ship globally to Europe, the Middle East, and Vietnam, ensuring fast delivery and competitive pricing. Request a wholesale quote today!