As a high-performance adhesive, PUR hot melt glue (polyurethane hot melt glue) has been widely used in many industries due to its excellent bonding strength, temperature resistance and moisture resistance. The curing process of PUR hot melt glue is one of the keys to its performance, so understanding the curing time of PUR hot melt adhesive and the factors that affect its curing speed is crucial for practical application.

In this article, we will explore the curing time, curing mechanism and factors that affect the curing time of PUR hot melt glue in detail to help users better understand and utilize this adhesive.

What is the curing principle of PUR hot melt glue?

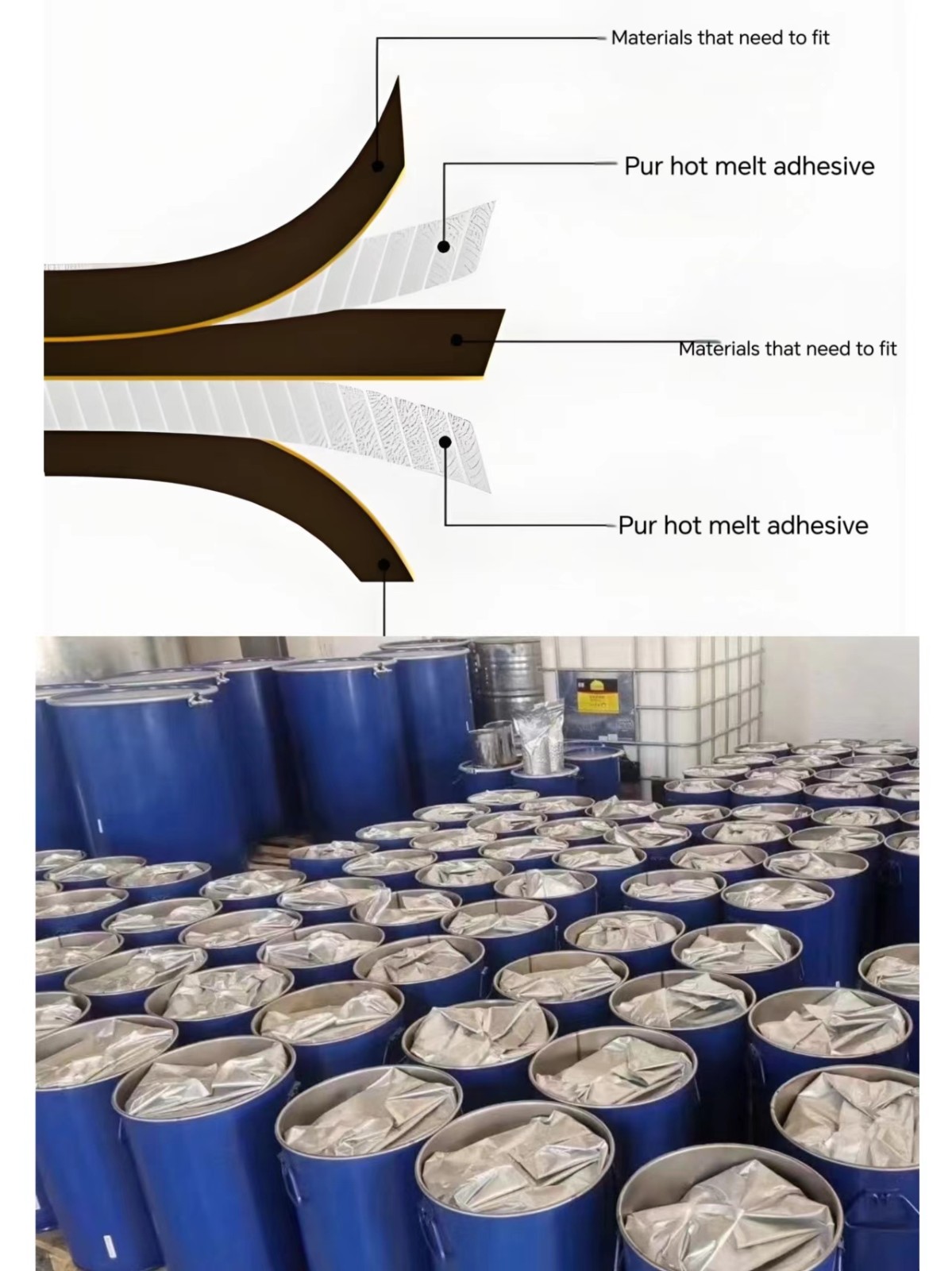

The biggest difference between PUR hot melt glue and common hot melt adhesives (such as EVA hot melt glue) is its curing mechanism. The curing of other hot melt adhesives usually depends on cooling and the reaction of the curing agent, while PUR hot melt adhesive is cured by chemical reaction. During the curing process of PUR hot melt glue, the isocyanate group (-NCO) in the adhesive reacts with moisture in the air to form a polyurethane structure and release carbon dioxide.

This chemical reaction not only enables PUR hot melt adhesive to provide strong adhesion, but also allows the curing process to be carried out at room temperature, although the curing time is relatively long. Because the reaction is related to moisture in the environment, the curing process of PUR hot melt glue is usually completed between a few hours and 24 hours, depending on the humidity of the environment and the formulation of the adhesive.

How long does it take for PUR hot melt glue to cure?

The curing time of PUR hot melt glue is generally divided into initial curing time (about 15 seconds to 1 minute) and full curing time (usually 24 hours). Understanding the difference between the two is crucial to the correct use of PUR hot melt glue.

1. Initial curing time of PUR hot melt glue

When PUR hot melt glue is first applied to the substrate, it will undergo a rapid solidification phase, which is usually very short, generally a few seconds to a few minutes. This is because after the PUR hot melt adhesive is applied, the adhesive layer begins to react with the moisture in the air to form initial adhesion. The length of the initial curing time depends mainly on the following factors:

● Ambient humidity: The curing speed of PUR hot melt glue is closely related to the humidity in the air. In an environment with high humidity, PUR hot melt glue will cure relatively quickly. Conversely, when the humidity is low, the curing speed is slower.

● Adhesive type: PUR hot melt glue with different formulations has different curing speeds. Some PUR hot melt glues may contain accelerators that can shorten the initial curing time and provide faster operation time.

● Coating thickness: The thickness of the coating layer will also affect the initial curing time. Thinner coatings usually cure faster, while thicker coatings may take longer to complete the initial curing.

Typically, PUR hot melt glue will complete the initial curing between 15 seconds and 1 minute. After this process is completed, the bonded parts can be subsequently processed, such as assembly, transportation, etc.

2. PUR hot melt glue complete curing time

Although PUR hot melt glue can provide a certain bonding strength after initial curing, to achieve maximum bonding strength, PUR hot melt glue needs to go through a complete curing process. This process involves further reaction of the isocyanate groups in the adhesive with moisture to form a stronger polyurethane structure. It usually takes a long time for PUR hot melt adhesive to fully cure, usually within 24 hours.

● Effect of air humidity: In high humidity environments, PUR hot melt glue cures faster, usually reaching high bond strength within a few hours. In low humidity environments, full cure may take longer, especially in dry seasons or low humidity areas.

● Effect of temperature: Temperature also has a significant effect on the curing process of PUR hot melt glue. Higher ambient temperatures can accelerate the curing reaction, while lower temperatures may cause the curing process to slow down. In cold environments, the curing time of PUR hot melt glue may be extended, so special attention should be paid to the temperature of the construction environment.

● Adhesive formulation: Different brands and types of PUR hot melt glue have different curing times. Some PUR hot melt glue formulations may have accelerators added to shorten the full cure time and provide a shorter production cycle.

Typically, within 24 hours, PUR hot melt glue can fully cure and reach its maximum bonding strength, but this also depends on the specific environmental conditions and adhesive type.

What affects the curing time of PUR hot melt adhesive?

In addition to ambient humidity and temperature, there are several factors that affect the curing time of PUR hot melt glue. Understanding these factors can help users control the curing process more accurately, improve work efficiency and bonding results.

1. The substrate used by PUR hot melt glue

The curing time of PUR hot melt glue is not only affected by environmental factors, but also closely related to the substrate used. The surface properties of different materials will affect the moisture absorption rate of PUR hot melt glue, thereby affecting the curing time.

● Hygroscopic substrates (such as wood, paper): These materials can absorb and transfer moisture, accelerate the curing reaction of PUR hot melt adhesive glue, so they can usually cure within 24 hours after bonding.

● Non-hygroscopic substrates (such as metal, glass, plastic): Since these materials do not provide additional moisture, PUR hot melt glue relies entirely on moisture in the air for curing, so the curing time may take 48 hours or even longer.

When selecting PUR hot melt glue, the surface characteristics of the substrate used need to be taken into account to optimize the curing process.

2. PUR hot melt glue thickness

The thicker the PUR hot melt adhesive layer, the longer it takes to cure. Since the curing of PUR hot melt glue depends on surface moisture absorption, it is difficult for moisture to penetrate the thicker glue layer, so it takes longer to fully cure. For example, PUR hot melt adhesive glue with a thickness of less than 0.5mm can usually cure within 24 hours, while a layer thicker than 1mm may take more than 48 hours to fully cure.

3. PUR hot melt glue application method

The application method of PUR hot melt glue will also affect its curing time. Usually, hot melt adhesive is applied by hot melt adhesive gun or other equipment. The uniformity of the glue layer and the coating method during application will affect the curing efficiency of the glue layer. Uniform and appropriate thickness of coating can help PUR hot melt glue cure faster.

● Spot coating or thin coating: Since moisture can penetrate faster, PUR hot melt adhesive cures in a shorter time, usually in about 24 hours.

● Thick coating or closed coating: If the PUR hot melt adhesive layer is thick or the coating surface is closed (such as between two airtight materials), the moisture in the air cannot effectively penetrate into it, and the curing time may be extended to more than 48 hours.

4. Air humidity and temperature

The chemical curing of PUR hot melt glue depends on the moisture in the air, so humidity and temperature are two key factors affecting the curing time of PUR hot melt adhesive. In a closed space, when the air circulation is not smooth, the humidity is high, and the curing reaction of hot melt adhesive may be slower. On the contrary, in a well-ventilated environment, the curing time will be faster.

● High humidity (more than 50%): PUR hot melt adhesive can absorb moisture faster, speed up the chemical curing process, and may reach full curing within 12-24 hours.

● Low humidity (less than 30%): PUR hot melt adhesive glue absorbs moisture slowly, and it may take 24-48 hours or even longer to fully cure.

● Temperature influence: The optimal curing temperature is usually between 20°C-30°C. If the temperature is low (such as below 10°C), the chemical reaction rate of PUR hot melt adhesive glue will decrease, and the curing time may be extended.

Curing time of PUR hot melt glue in different industry scenarios

● Packaging industry: In the packaging industry, PUR hot melt glue is usually used for bonding cartons, plastic packaging, composite materials, etc. Since paper and some plastics have certain hygroscopicity, the curing time of PUR hot melt adhesive is usually within 24 hours.

● Woodworking industry: Wood itself has good hygroscopicity, which can accelerate the curing of PUR hot melt glue. Therefore, in applications such as furniture manufacturing and wood board lamination, the curing time of PUR hot melt glue is generally 12-24 hours.

● Electronics industry: PUR hot melt glue in electronic products is usually used for sealing, potting and structural bonding. Since most electronic components are made of metal or plastic, the curing time of PUR hot melt glue is longer, which may take 24-48 hours.

● Automobile manufacturing: In the automobile manufacturing process, PUR hot melt glue is mainly used for headlight bonding, interior fixing, body sealing, etc. Since automotive materials are usually metal, glass or plastic, the curing time of PUR hot melt glue is relatively long, usually 24-48 hours. If the adhesive application area is thicker or has better sealing, the curing time may be longer.

● Shoe industry: In the process of shoe manufacturing, PUR hot melt adhesive glue is mainly used for sole bonding, upper fixation, etc. Since some leather or textile materials can absorb moisture, the curing time of PUR hot melt glue is generally around 24 hours.

How to speed up the curing speed of PUR hot melt glue?

In order to improve production efficiency, many companies hope to shorten the curing time of PUR hot melt adhesive glue as much as possible. Here are several ways to speed up the curing of PUR hot melt glue:

1. Increase the humidity of the environment: Properly increase the air humidity (40%-60%), which can accelerate the moisture absorption and curing process of PUR hot melt glue.

2. Increase air flow: Proper ventilation helps to provide moisture faster and increase the curing speed of PUR hot melt adhesive.

3. Control the thickness of hot melt adhesive: Avoid too thick glue layer, so that moisture can penetrate more easily.

4. Increase the temperature of glue application: Appropriately increase the heating temperature of PUR hot melt glue to make it more evenly coated and achieve a better initial bonding effect in a short time.

Wholesale hot melt adhesive from Dongguan Tingjie

Dongguan Tingjie Decoration Materials Co., Ltd. offers wholesale hot melt glues that are both affordable and high-quality. We specialize in PVC, ABS , and wood grain edge banding strips in a variety of profiles, including T-type and U-type, and also produce hot melt glue. As a reliable manufacturer and supplier based in Dongguan, China, we cater to customers globally, offering bulk discounts and competitive quotes. Our factory’s production capacity ensures that large orders are processed efficiently, allowing you to buy the materials you need at the best prices.