As an efficient, environmentally friendly and easy-to-operate adhesive material, industrial hot melt adhesive has been widely used in many industries, including packaging, electronics, automobile manufacturing, furniture production, etc. Due to its rapid curing, no need for solvents, non-toxic and environmentally friendly characteristics, industrial hot melt glue plays an important role in all walks of life.

However, different types of industrial hot melt adhesives have different performance characteristics and application fields. Among the many types of industrial hot melt glue, EVA (ethylene-vinyl acetate copolymer) industrial hot melt glue and PUR (polyurethane) industrial hot melt adhesive are the two most common and widely used adhesives.

This article will start with the applicable fields of industrial hot melt adhesive, introduce in detail the most suitable application scenarios of industrial hot melt glue, and focus on analyzing the differences and selection guidelines between EVA and pur hot melt glue to help users in various industries better choose the appropriate type of industrial hot melt glue.

What is the most suitable application of industrial hot melt glue?

Industrial hot melt adhesive has been widely used in many industries due to its unique properties, especially in terms of curing speed, environmental protection and convenience.

The five most suitable uses for industrial hot melt glue:

1. Packaging industry

2. Woodworking industry

3. Electronics industry

4. Automobile industry

5. Textile and footwear industry

1. Packaging industry

The packaging industry is one of the most widely used fields for industrial hot melt adhesive. In the packaging process, industrial hot melt glue is usually used for box packaging, label attachment, carton sealing and foam plastic packaging. Compared with traditional solvent-based adhesives, industrial hot melt adhesive does not require drying time and can cure quickly, which significantly improves production efficiency.

The advantages of hot melt glue in the packaging industry are mainly reflected in the following aspects:

● Fast bonding: In the packaging line, industrial hot melt adhesive can quickly bond various cartons, cardboards and plastic films, thereby improving work efficiency.

● Environmental protection and pollution-free: Industrial hot melt glue does not contain solvents and will not release harmful gases or exhaust gases when used, which meets the requirements of modern environmentally friendly production.

● Wide applicability: Industrial hot melt glue can bond a variety of packaging materials, including paper, plastic, metal, etc., with strong adaptability and high bonding strength.

2. Woodworking industry

Industrial hot melt adhesive is widely used in the woodworking industry. Whether it is a home woodworking project or a large industrial application, industrial hot melt glue is considered a first-class woodworking glue choice.

The main uses of hot melt adhesive in the woodworking industry include:

● Product assembly: Industrial hot melt glue is widely used in the assembly process of woodworking products, which can provide fast and strong bonding effects, especially suitable for the manufacture of small furniture and wooden frames.

● Lamination: When laminating wood and veneer materials, industrial hot melt adhesive can effectively bond different surface materials such as thin wood boards, decorative papers and fiberboards.

● Sealing and labeling: Industrial hot melt glue is also used for sealing, surface treatment and label bonding of wood products. It can cure in seconds to ensure an efficient workflow.

The advantages of industrial hot melt glue in the woodworking industry are its easy operation, fast curing speed, and the ability to quickly bond wood at room temperature, reducing waiting time during the production process.

3. Electronics industry

The assembly, packaging and sealing of electronic products are another major application area of industrial hot melt glue. As electronic equipment develops towards miniaturization and integration, the use of industrial hot melt adhesive is also increasing, especially in the production process of mobile phones, home appliances, automotive electronics and other products.

The role of hot melt adhesive in the electronics industry is mainly reflected in:

● Assembly: In the assembly of parts of electronic products, industrial hot melt glue can be used to fix components and provide fast and strong bonding effects.

● Sealing and waterproofing: Electronic equipment usually requires waterproof sealing in certain parts, and industrial hot melt glue can provide effective protection in these key parts.

● Fixing and insulation: Industrial hot melt glue can also be used for insulation and fixing of components to prevent vibration and improve durability.

The requirements for industrial hot melt adhesive in the electronics industry are high, especially in terms of temperature resistance, impact resistance and electrical insulation performance.

4. Automotive industry

In the process of automobile manufacturing, industrial hot melt glue is used to bond interior parts, seal waterproof strips, install glass, repair external plastic parts, etc.

The application of hot melt glue in the automotive industry has the following advantages:

● Efficient bonding: In automobile production, industrial hot melt glue can quickly bond parts of different materials to improve assembly efficiency.

● Temperature resistance: Industrial hot melt adhesive can withstand temperature changes in the internal and external environment of the car and maintain bonding strength.

● Anti-seismic performance: Industrial hot melt glue has certain anti-seismic performance, which can effectively reduce the impact of vibration on parts during driving.

The automotive industry has diversified demands for industrial hot melt glue, requiring it to have good bonding performance, as well as certain temperature resistance and impact resistance.

5. Textile and footwear industry

Industrial hot melt glue is widely used in the textile and footwear industry, mainly used for bonding of soles, bonding of clothing and home textile products, and processing of other fabrics.

The application advantages of hot melt glue in the textile and footwear industries are as follows:

● High bonding strength: Industrial hot melt glue can provide strong bonding, especially for high-strength bonding of footwear and clothing.

● Easy processing: Since industrial hot melt glue has a short curing time, it can greatly improve production efficiency and reduce waiting time.

● Environmentally friendly: Industrial hot melt glue has no solvent components and meets the environmental protection requirements in the textile production process.

How to choose EVA and pur hot melt glue?

Among the many types of industrial hot melt adhesives, EVA (ethylene-vinyl acetate copolymer) and PUR (polyurethane) industrial hot melt glue are two common types of industrial hot melt glue. They each have different characteristics and application scenarios. Understanding their advantages and disadvantages and applicable fields will help choose the appropriate type of industrial hot melt glue.

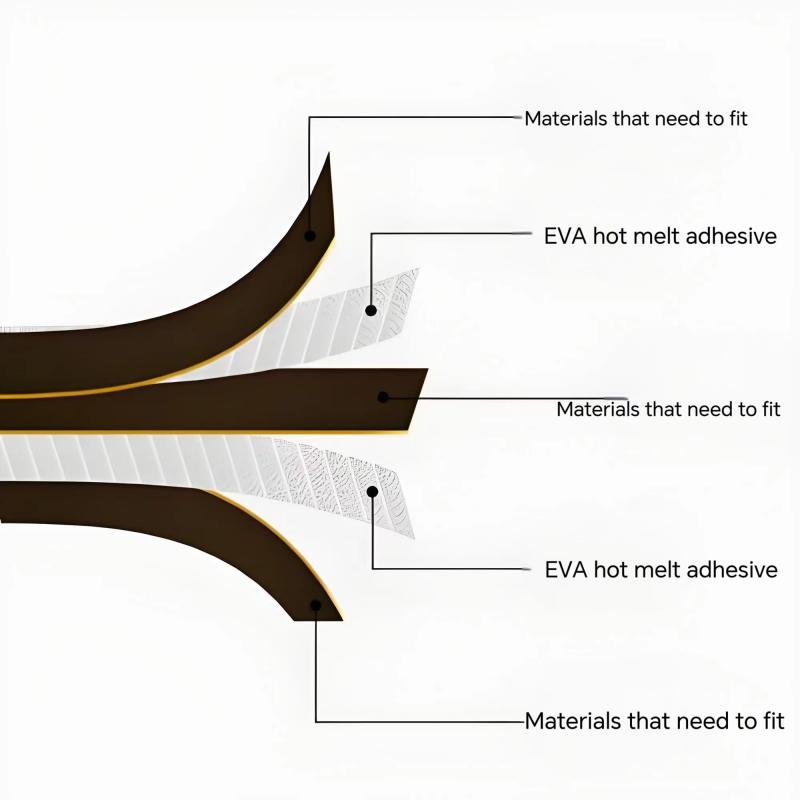

1. EVA hot melt glue

EVA hot melt glue is composed of ethylene and vinyl acetate copolymers, and is usually transparent and flexible. The main features of EVA hot melt glue include:

● Low cost: Compared with pur hot melt glue, EVA hot melt glue has a lower production cost and is suitable for the mid- and low-end markets.

● Fast curing: EVA hot melt glue has a faster curing speed and is suitable for efficient production environments.

● Wide applicability: EVA hot melt glue can bond a variety of substrates, such as paper, plastic, wood, etc., and is widely used in packaging, woodworking, stationery and other industries.

● Poor temperature adaptability: EVA hot melt glue has poor temperature resistance and can generally only withstand lower working temperatures (usually between 60-70°C). In high temperature environments, the bonding strength of EVA hot melt glue will decrease.

Therefore, EVA hot melt glue is most suitable for applications that do not require high bonding strength and have low working temperatures, such as paper product packaging, toys, stationery and other industries.

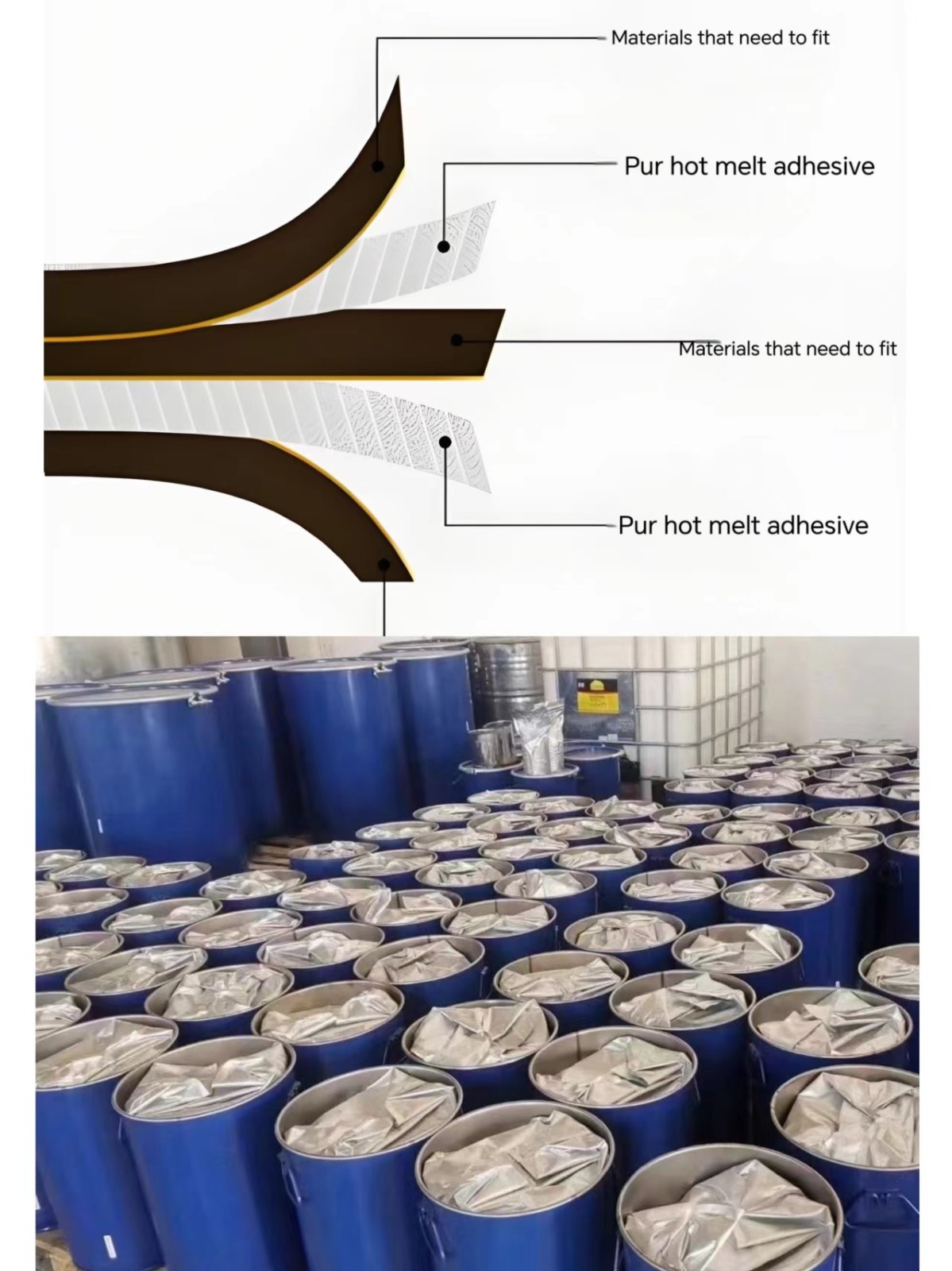

2. Pur hot melt glue

Pur hot melt glue is made of polyurethane material, has strong adhesion and good temperature resistance, and is particularly suitable for applications that need to withstand higher temperatures and larger loads. The main features of pur hot melt glue include:

● High bonding strength: Pur hot melt glue can provide very strong bonding after curing, and is suitable for applications requiring high-strength bonding.

● Good temperature resistance: Pur hot melt glue can maintain good bonding performance at higher temperatures and is suitable for bonding in high-temperature environments.

● Strong moisture and chemical resistance: Pur hot melt glue has strong resistance to moisture and chemicals and is suitable for occasions that require moisture resistance or corrosion resistance.

● Higher cost: Compared with EVA hot melt glue, pur hot melt glue has a higher cost and is usually used for high-end products and applications requiring high-performance bonding.

Pur hot melt glue is usually used in industries such as automobiles, electronics, and construction that have high requirements for bonding strength and temperature resistance, and is especially suitable for bonding automotive interiors and electronic components.

Therefore, for applications that require fast curing and low cost, EVA hot melt glue is undoubtedly an ideal choice; while for applications that require high bonding strength and temperature resistance, pur hot melt glue is more suitable. Choosing the right industrial hot melt adhesive according to different process requirements and industry needs can ensure the maximum production efficiency and product quality.

Buy High-Quality hot melt adhesive from Dongguan Tingjie

If you are looking to buy high-quality industrial hot melt adhesiveat affordable prices, Dongguan Tingjie Decoration Materials Co., Ltd. is your ideal supplier. As a China-based manufacturer, we offer a wide range of edge banding products including PVC, ABS, wood grain options, and hot melt adhesive. Our factory can produce over 10,000 tons annually to meet the demands of businesses worldwide. Contact us today!