Hot melt glue is an adhesive widely used in various industrial fields. Hot melt adhesive glue has become the first choice for many manufacturing and packaging industries due to its unique curing method and convenient operation characteristics. However, just like any technology and material, hot melt glue provides advantages while also accompanied by some disadvantages that cannot be ignored.

In this article, we will explore the advantages and disadvantages of hot melt glue in detail and analyze its performance characteristics in order to provide a more scientific and professional reference for practitioners in related industries.

What is hot melt glue?

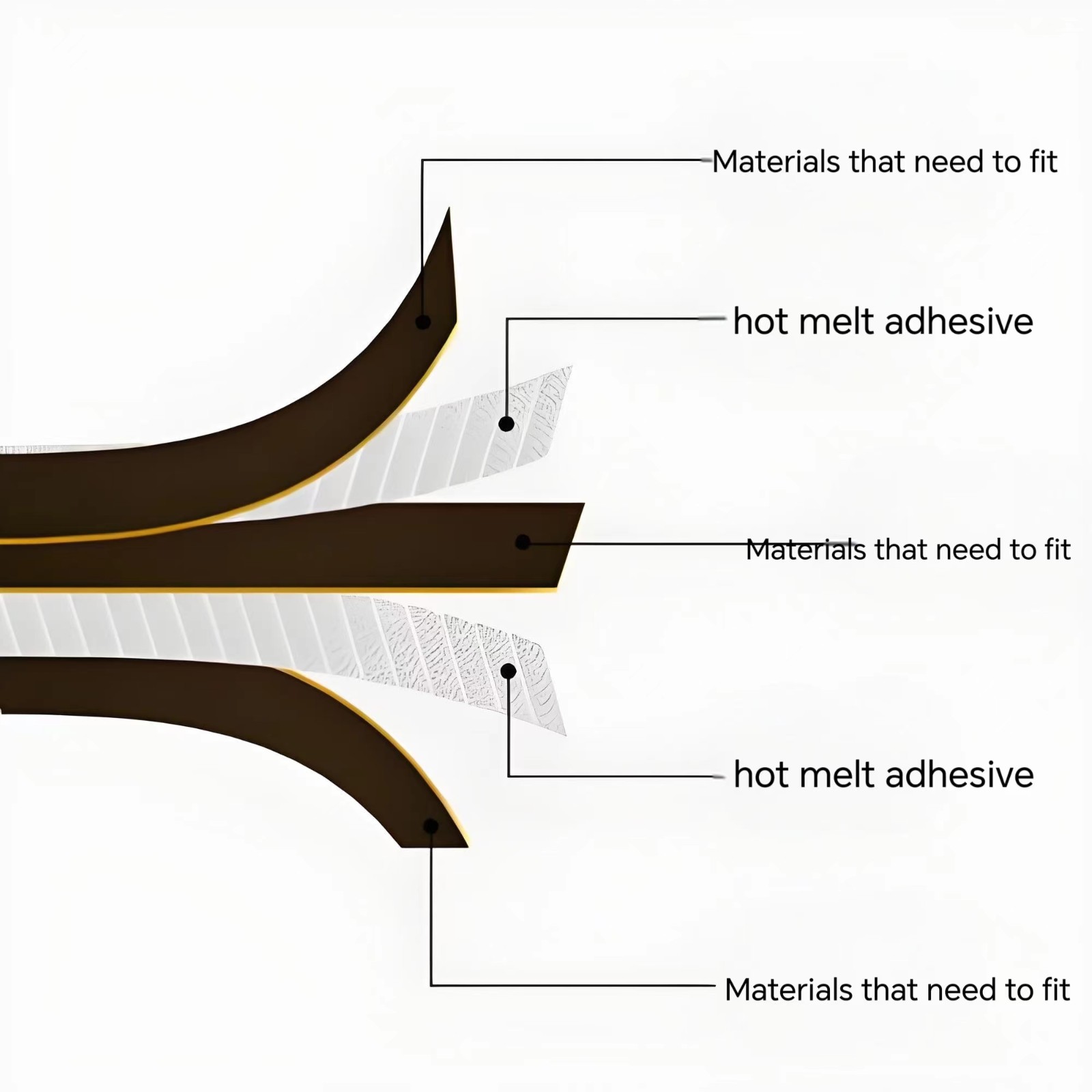

Hot melt glue is a solvent-free solid adhesive, usually composed of resin, wax, polymer and other components. It is applied by heating and melting into a liquid state, and solidifies after cooling to form a strong bond. Common types of hot melt glue include EVA (ethylene-vinyl acetate copolymer), PO (polyolefin), PA (polyamide), PU (polyurethane), etc. Hot melt glue is easy to use and has a fast bonding speed, so it is widely used in packaging, automobile manufacturing, electronic equipment, woodworking, textiles and other industries.

The biggest feature of hot melt adhesive glue is its "hot melt" property, which means that it changes from solid to liquid after being heated to a certain temperature, and becomes solid again after cooling. This curing process is different from common liquid adhesives. It does not require a long-term chemical reaction, but achieves bonding through temperature changes, which makes hot melt adhesive glue have high working efficiency and operational flexibility.

What are the advantages of hot melt adhesive glue?

Advantages of hot melt glue:

1. Fast curing, improving production efficiency

2. No solvent components, environmentally friendly and pollution-free

3. High bonding strength

4. No additional drying time required

5. Good operability and adaptability

1. Fast curing, improving production efficiency

One of the biggest advantages of hot melt glue is its fast curing property. After coating, hot melt adhesive glue solidifies quickly during the cooling process, and usually achieves strong bonding strength within a few seconds. This feature is particularly important in high-speed production lines, especially in industries such as packaging, electronics, and furniture, which can significantly improve production efficiency and shorten production cycles.

2. No solvent components, environmentally friendly and pollution-free

The formula of hot melt glue does not contain any solvent components, so it will not release harmful gases or solvents during use, which makes it an environmentally friendly material. Compared with traditional solvent-based adhesives, hot melt adhesive glue has obvious environmentally friendly advantages and meets the requirements of modern green production. The use of hot melt glue not only helps to reduce industrial waste gas emissions, but also helps to improve the working environment.

3. High bonding strength

After curing, hot melt adhesive glue can form a strong bond, which is particularly suitable for occasions that require fast and strong bonding. It can bond a variety of different substrates, including paper, plastic, metal, glass, wood, etc. This wide range of applicability makes hot melt adhesive glue play an important role in applications in various industries.

4. No additional drying time required

Unlike many liquid adhesives, hot melt adhesive glue does not require waiting for drying or curing time. It can be used immediately after cooling, which is of great significance to improving the work efficiency and flexibility of the production line. Especially in occasions where a large number of bonding operations need to be carried out quickly, the advantage of hot melt glue without drying time enables it to meet the needs of efficient production.

5. Good operability and adaptability

Hot melt adhesive glue can be adjusted by temperature control equipment during use to adapt to the use requirements under different temperature conditions. According to different process requirements, hot melt glue can be heated to a suitable bonding state at different temperatures. At the same time, hot melt glue is easy to use and is usually operated by hot melt glue gun or automatic coating equipment, which greatly reduces the difficulty of operation.

What are the disadvantages of hot melt adhesive glue?

Although hot melt adhesive glue has advantages in many aspects, it also has certain limitations, especially in some special environments, it may not meet all application requirements. Below, we will analyze the main disadvantages of hot melt adhesive glue in detail.

Disadvantages of hot melt glue:

1. Limited strength and heat resistance

2. Poor moisture resistance

3. Poor bonding effect on some materials

4. Brittle and poor impact resistance

5. Poor aging resistance

6. High construction environment requirements

1. Limited strength and heat resistance

The strength and heat resistance of hot melt glue are relatively low, especially in high temperature environments, it is easy to lose its bonding properties. The curing process of hot melt glue is reversible, and most hot melt glue will begin to lose its bonding strength when the temperature exceeds 77°C. This means that hot melt adhesive glue cannot provide long-term stability in high-temperature environments. For example, in the bonding of automotive parts, hot melt glue may not be able to withstand the high temperature environment in the engine compartment, resulting in bonding failure. Therefore, the heat resistance and long-term strength of hot melt glue are a significant disadvantage in certain high-temperature, high-stress applications.

2. Poor moisture resistance

The moisture resistance of hot melt glue is relatively poor. The presence of moisture or water will affect the bonding strength of hot melt adhesive glue, especially in high humidity environments, hot melt glue may not be able to firmly bond some surfaces, resulting in reduced bonding performance. Therefore, for some humid or underwater environments, hot melt adhesive glue is not an ideal choice. For example, in industries such as outdoor construction and shipbuilding that require strong waterproofing, hot melt glue may not meet the requirements.

3. Poor bonding effect on some materials

Although hot melt glue is suitable for bonding a variety of materials, for some special materials, hot melt adhesive glue may not be as good as other types of adhesives. For example, when bonding plastics with low surface energy (such as polyethylene and polypropylene), hot melt glue may have poor adhesion, resulting in a weak bond. To solve this problem, it is usually necessary to treat the surface of these substrates (such as plasma cleaning, flame treatment, etc.) to improve the bonding effect of hot melt adhesive glue.

4. Brittle and poor impact resistance

Although hot melt adhesive glue can provide strong bonding strength, it has poor toughness and impact resistance. When subjected to external impact or pressure, hot melt glue may break or fail. This is not the best choice for applications that need to withstand mechanical pressure or vibration. Therefore, the use of hot melt glue is limited in products such as automobiles, home appliances, and electronic equipment that require strong impact resistance.

5. Poor aging resistance

Hot melt glue has poor aging resistance and may become brittle, crack, or lose its bonding effect over time, especially when exposed to ultraviolet rays, oxygen, or temperature changes for a long time. For some products that need to be used for a long time or exposed outdoors for a long time, hot melt glue may not provide sufficient bonding stability. Therefore, in this environment, it may be necessary to choose other types of adhesives to replace hot melt adhesive glue.

6. The construction environment has high requirements

Hot melt glue requires specific equipment and temperature control when used, especially in large-scale production, and the adjustment and maintenance of the equipment require certain technical support. High temperature operation may also bring safety hazards, especially in the production process, improper handling may cause burns or equipment failure. Therefore, when using hot melt adhesive glue, factories and operators need to have certain professional knowledge and skills.

Dongguan Tingjie – Manufacturer of PVC and ABS Edge Banding Strips

Dongguan Tingjie Decoration Materials Co., Ltd. is an established manufacturer of edge banding materials. Based in Dongguan, China, we produce PVC, ABS, and wood grain edge banding strips, as well as hot melt adhesive glue and T-type and U-type profiles. We are proud to offer low-price options without sacrificing quality, ensuring that businesses around the world can purchase the materials they need at competitive prices. For bulk buyers, we offer attractive wholesale rates and discounts.