As an important material widely used in furniture manufacturing and decoration industries, the manufacturing process of PVC edge banding involves multiple process steps. These steps ensure that PVC edge banding tape not only has excellent durability and adaptability, but also meets the market's requirements for appearance and function.

This article will introduce the production process of PVC edge banding in detail, from the selection of raw materials to the completion of the final product, to help readers fully understand this production process.

What is PVC edge banding?

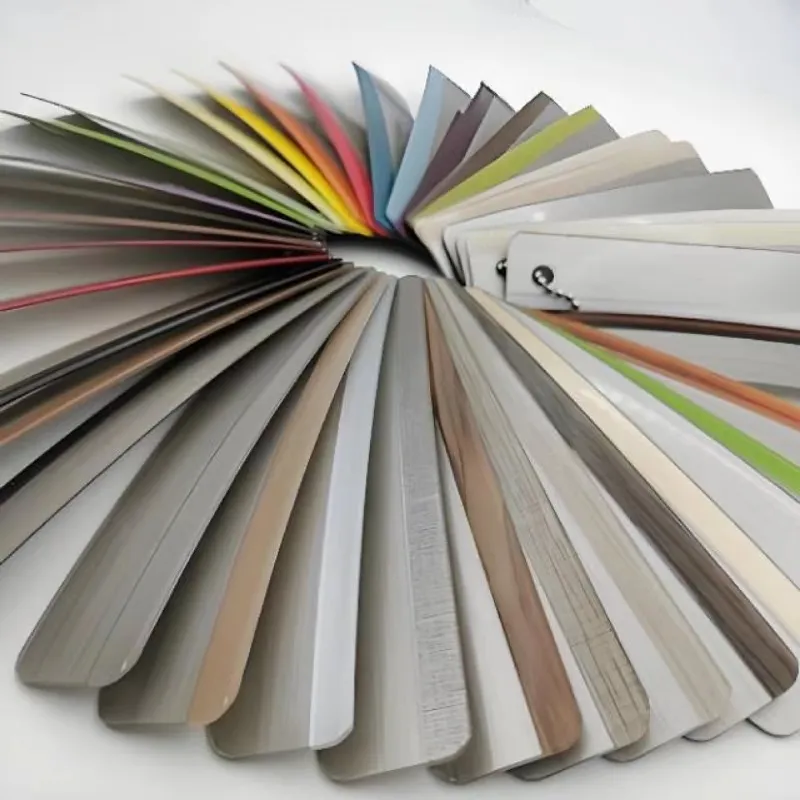

PVC edge banding is an edge banding product made of polyvinyl chloride (PVC) as the main raw material, mainly used for edge banding of wood panels. It can not only beautify the appearance of furniture, but also effectively protect the edge of wood from external factors such as moisture, wear and pollution. PVC edge banding is widely used in furniture, cabinets, floors and other products, especially suitable for use in home decoration, and has a strong market demand.

PVC edge banding tape usually has good water resistance, stain resistance, impact resistance and wear resistance. Therefore, PVC edge banding tape is not only suitable for home environments, but also can withstand high frequency use.

What are the raw materials for the manufacture of PVC edge banding?

The key to making PVC edge banding is to choose the right raw materials. Usually, the main component of PVC edge banding tape is polyvinyl chloride resin (PVC resin), and other chemicals and additives are added according to the needs. The following are the common raw material compositions of PVC edge banding:

1. PVC resin

PVC resin is the main component of PVC edge banding, which determines the physical properties of the final product. PVC resin has good plasticity, stability and chemical resistance, so it is widely used in various fields. PVC resin has many types, and resins with different properties can be selected according to different application requirements.

2. Plasticizer

In order to increase the flexibility of PVC edge banding tape, plasticizers are usually added. Plasticizers can effectively improve the processability of PVC edge banding, making it less likely to break during use, and enhancing the durability and impact resistance of the edge banding.

3. Stabilizer

In the processing of PVC, thermal stability is an important indicator, especially in the processing process at high temperature. Stabilizers can effectively improve the thermal stability of PVC and prevent the degradation reaction of PVC resin at high temperature, thereby ensuring the quality of the finished edge banding.

4. Fillers

In order to improve the strength and rigidity of PVC edge banding, fillers are often added to PVC resin. Common fillers include calcium powder, talcum powder, etc. These fillers can not only improve the hardness of PVC edge banding tape, but also help reduce production costs.

5. Pigments and colorants

In order to meet the diverse color needs in the market, pigments or colorants are also needed in PVC edge banding tape. The choice of pigments and colorants determines the appearance of PVC edge banding tape, such as common wood grain effects, solid colors or glossy effects.

6. Other additives

In addition to the above main raw materials, some special additives such as anti-ultraviolet agents and antibacterial agents may also be added to enhance the performance of PVC edge banding tape. For example, anti-ultraviolet agents can effectively prevent the edge banding from fading or aging when exposed to sunlight; antibacterial agents can inhibit the growth of bacteria and ensure the safety of edge banding in humid environments.

What is the manufacturing process of PVC edge banding?

The production process of PVC edge banding is generally divided into 6 important steps: raw material preparation, extrusion molding, cooling and shaping, cutting and trimming, surface treatment, inspection and packaging. Each step plays a vital role in the quality and performance of PVC edge banding tape.

1. Raw material preparation

First, you need to prepare the raw materials needed to make PVC edge banding. According to the formula, PVC resin, plasticizer, filler, stabilizer, pigment and other additives are mixed in a certain proportion. This process is usually completed using a mixer to ensure that all raw materials are fully uniform.

2. Extrusion molding

The mixed raw materials will enter the extruder for processing. The extruder is a high-temperature heating device that can heat the raw materials to about 200 degrees Celsius until the PVC resin is completely melted. The molten PVC will be extruded through the die to form the preliminary shape of the edge banding.

The working principle of the extruder is to push the material into the die head through the screw and heat it to a molten state, and then extrude it through the molding port of the die. The thickness, width and shape of the PVC edge banding tape will be determined by the design of the die. This process requires strict control of temperature, pressure and extrusion speed to ensure the uniformity and stability of the PVC edge banding tape.

3. Cooling and shaping

The extruded PVC edge banding will enter the cooling system and be cooled by a cooling water tank or air cooling device. Cooling is a key step in the curing and molding of the edge banding. As the temperature decreases, the molten PVC material becomes harder, and the shape of the edge banding gradually stabilizes and reaches the final hardness.

4. Cutting and trimming

The cooled PVC edge banding will be cut by a cutting machine to ensure that the length of the edge banding meets the requirements. The accuracy of cutting directly affects the quality of the product, so high-precision cutting equipment is required to complete this link. In order to avoid burrs or irregular cuts during the cutting process of the PVC edge banding tape, the cut edges are usually further trimmed.

5. Surface treatment

Surface treatment is an indispensable part of the production process of PVC edge banding. According to market demand, the surface of the edge banding can be treated in a variety of ways, such as UV coating, printing, film lamination, etc. Through UV coating treatment, the surface of the edge banding can not only improve its wear resistance and weather resistance, but also enhance the gloss and improve the appearance.

In addition, printing and laminating processes can add various patterns, textures or imitation wood grain effects to PVC edge banding to enhance its market appeal. Common printing methods include thermal transfer and screen printing, which can achieve high-quality patterns and text effects on PVC edge banding tape to meet personalization and customization needs.

6. Inspection and packaging

The finished PVC edge banding will undergo quality inspection to ensure that the product's size, appearance, hardness, adhesion and other aspects meet the standards. Quality inspection usually includes appearance inspection, size inspection, wear resistance test, temperature resistance test, etc. Through strict inspection, ensure that each PVC edge banding tape meets the factory standards.

Qualified PVC edge banding will enter the packaging stage. The packaging must not only ensure that the product is not damaged during transportation and storage, but also be easy to sell and use. Generally, PVC edge banding tape will be packaged according to length and specifications, and equipped with product labels and relevant technical parameters to facilitate customer selection and use.

Post-processing and use of PVC edge banding

After the production process of PVC edge banding tape is completed, post-processing is required according to actual needs. Post-processing includes cutting, pasting, trimming and installation, etc. The specific steps depend on the furniture manufacturer or decoration requirements.

1. Cutting and installation

In actual applications, PVC edge banding is usually cut and installed according to specific usage requirements. It can be installed with a special hot melt glue gun or cold glue to fix the edge banding to the edge of the wooden board. During installation, it is necessary to ensure that the PVC edge banding tape fits tightly to the edge of the board and prevent air from entering.

2. Trimming and finishing

The edges of PVC edge banding tape may be uneven after installation, so it needs to be trimmed and finished. Use precision tools to repair the seams of the edge banding to ensure that the edges are neat and smooth. This not only improves the appearance, but also enhances the sealing and durability of the PVC edge banding tape.

Affordable Customized PVC edge banding from Dongguan Tingjie

At Dongguan Tingjie Decoration Materials Co., Ltd., we offer customized edge banding solutions tailored to your exact specifications. Whether you need PVC edge banding, ABS edge banding, or wood grain edge banding, we provide a variety of profiles including T-type and U-type. As a China-based manufacturer, we ensure high-quality products at affordable prices, with wholesale pricing and bulk discounts available for large orders!