As an adhesive widely used in industrial, commercial and domestic fields, hot melt glue has become the preferred bonding material in many industries due to its unique properties and ease of use. Hot melt adhesive has efficient bonding ability, fast curing characteristics, and is suitable for bonding a variety of materials.

This article will take a deep look at the materials that industrial hot melt adhesive is suitable for bonding, and analyze in detail how to use hot melt glue correctly to ensure the best results.

What is industrial hot melt glue?

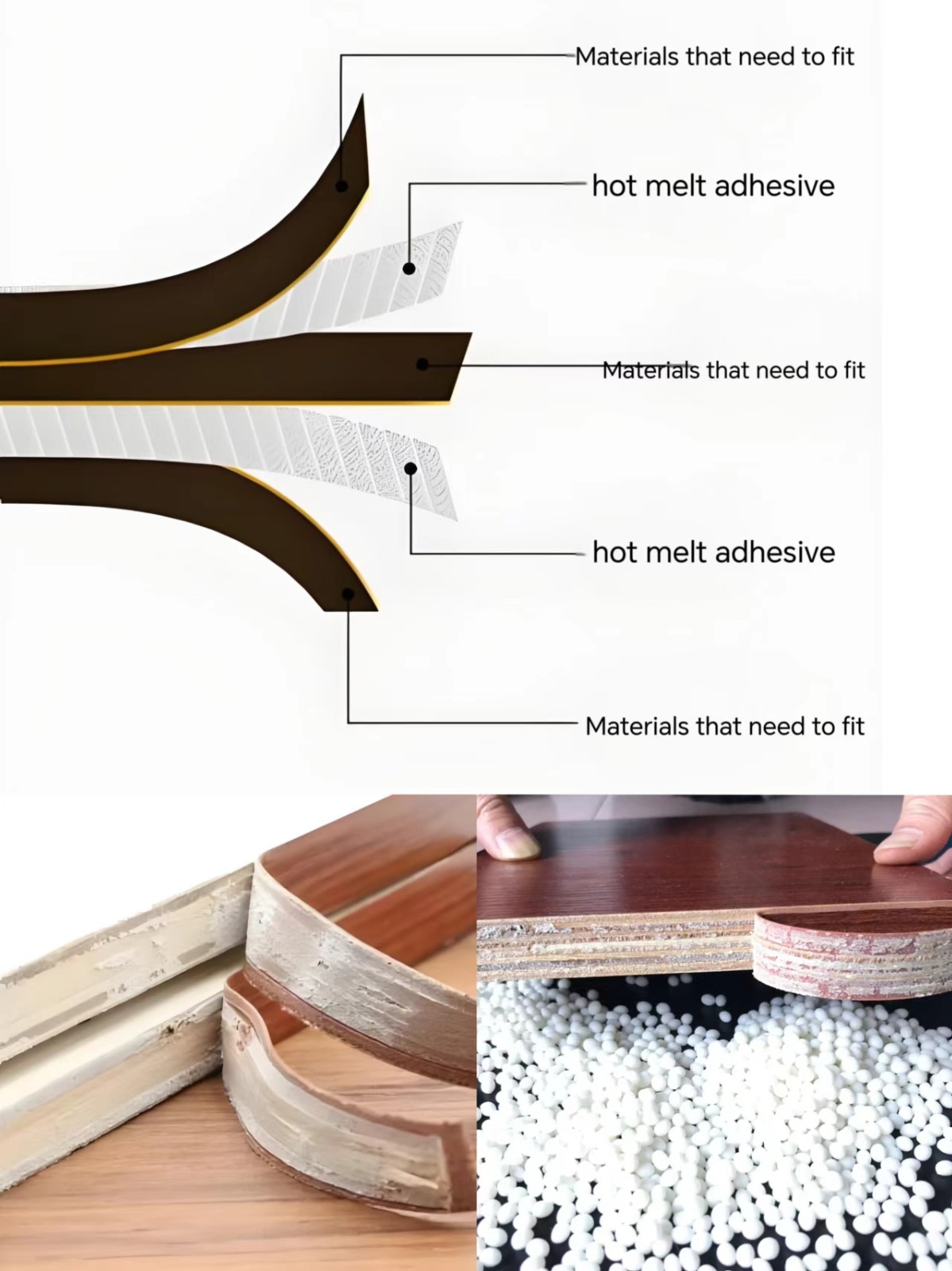

Industrial hot melt glue is a thermoplastic adhesive, which means that it becomes soft, fluid, and able to form a bond with different surfaces when heated. After cooling, industrial hot melt adhesive will quickly harden and form a strong bond. Industrial hot melt glue usually exists in the form of granules, strips or blocks. When used, it is heated and applied to the surface of the material to be bonded by an industrial hot melt glue gun. Its curing process requires almost no chemical reaction, but relies on temperature changes to quickly change from liquid to solid.

What materials can be bonded well with hot melt adhesive?

Industrial hot melt glue is widely used in many fields mainly due to its ability to bond a variety of materials. Materials that can be well bonded with hot melt glue include:

1. Paper and cardboard

2. Wood

3. Plastic

4. Metal

5. Textiles and leather

6. Ceramics and glass

1. Paper and cardboard: Industrial hot melt glue is widely used in the manufacturing and packaging industries of paper products. It can quickly bond paper and cardboard to form a strong bond. Especially in the packaging industry, industrial hot melt adhesive can quickly seal cartons, label stickers, and packaging of various paper products. Since paper and cardboard are usually porous materials, industrial hot melt adhesive can penetrate their surface and enhance the bonding strength.

How to use:

● Use the industrial hot melt glue gun to apply the melted industrial hot melt glue to the joint surface of the paper or cardboard.

● Ensure that the glue is evenly applied and quickly press the parts to be bonded. The bonding is completed after cooling.

● For large-area bonding, it is recommended to apply the hot melt adhesive in batches to avoid the glue cooling too quickly.

2. Wood: Wood is another material suitable for the use of industrial hot melt adhesive. Since the surface of wood usually has a certain degree of porosity, industrial hot melt adhesive can quickly penetrate and form a strong bond. Industrial hot melt glue is widely used in the woodworking industry, including furniture assembly, decorative wood bonding, etc.

How to use:

● Apply hot melt adhesive evenly on the contact surface of the wood, and be careful not to apply too thickly.

● After applying the glue, immediately butt the wood parts together and press them firmly to ensure the tightness of the joint.

● Wood usually needs a longer cooling time to ensure a strong bonding effect and ensure that it is fully cured before use.

3. Plastics: Industrial hot melt glue can bond most common plastic materials well, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), etc. Industrial hot melt glue shows good adhesion, especially in the bonding of plastics such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

However, if some plastic surfaces are not properly treated, the adhesion of industrial hot melt adhesive may be affected. Therefore, for these plastic surfaces, roughening or using special plastic adhesives can be used to enhance the bonding effect.

How to use:

● For plastic surfaces, first clean and remove impurities such as oil, dust, etc. to ensure that the bonding surface is clean.

● Apply hot melt adhesive evenly on the plastic surface to ensure that there is no omission.

● After applying the glue, quickly dock the plastic parts and maintain pressure until the hot melt adhesive solidifies.

4. Metal: Industrial hot melt glue can also bond well to metal surfaces, especially when the metal surface has been treated or coated with a special coating. When industrial hot melt glue is used for metal bonding, it has high bonding strength and can provide vibration and impact resistance.

However, since metal is a heat-conducting material, temperature changes during the curing process of industrial hot melt glue may affect the bonding effect. Therefore, when applied in a high-temperature environment, the selection of industrial hot melt adhesive should consider special types that are resistant to high temperatures.

How to use:

● Make sure the metal surface is clean and dry to improve the bonding strength.

● Use a hot melt adhesive gun to evenly apply glue on the metal surface.

● Apply slight pressure after docking and keep the parts in place until the industrial hot melt glue cools and solidifies.

5. Textiles and leather: Industrial hot melt adhesive can also be used for bonding textiles, leather and other flexible materials. It has been widely used in the manufacture of footwear, clothing and other leather products. Industrial hot melt glue can quickly bond these materials and provide strong durability.

How to use:

● Apply hot melt adhesive evenly on the seams of leather or textiles.

● Use special tools to press the seams to ensure a tight joint.

● For some weak materials, it may be necessary to increase the amount of glue applied according to actual conditions.

6. Ceramics and glass: Ceramics and glass usually require higher bonding strength due to their smooth and non-absorbent surfaces. Industrial hot melt glue can provide better bonding on ceramics and glass, but it is usually necessary to use high-performance industrial hot melt adhesive varieties, especially those hot melt adhesives designed for smooth surfaces.

How to use:

● Clean the ceramic or glass surface to ensure that it is free of oil, dust and moisture.

● Apply an even layer of industrial hot melt glue on the contact surface and quickly butt the materials together.

● Apply slight pressure to ensure complete bonding and keep it for a certain period of time to wait for curing.

How to use industrial hot melt glue correctly?

Correct use of industrial hot melt adhesive is an important step to ensure the bonding effect. 5 key steps and tips for using industrial hot melt glue:

1. Choose the right hot melt adhesive

2. Heat the hot melt glue

3. Apply the hot melt adhesive

4. Quickly dock and apply pressure

5. Cool and cure

1. Choose the right hot melt adhesive: There are many types of industrial hot melt glue, including EVA, PUR, SBS and many other types. Different types of industrial hot melt adhesive are suitable for different materials and applications. Therefore, when using hot melt adhesive, you should choose the right industrial hot melt glue according to the type of bonded material and the bonding requirements. For example, EVA hot melt glue is usually suitable for bonding paper, cardboard and wood, while PUR hot melt glue is suitable for materials that require high strength and moisture resistance.

2. Heat the hot melt glue: Industrial hot melt adhesive needs to be heated to a molten state before use. When using a hot melt adhesive gun, make sure the temperature is adjusted properly and wait for the industrial hot melt adhesive to melt completely. Too high or too low a temperature will affect the bonding effect of industrial hot melt glue. Typically, the melting temperature of industrial hot melt glue ranges from 160°C to 200°C.

3. Applying hot melt adhesive: When applying industrial hot melt glue, ensure that the coating is even and do not apply too much. Too thick a layer of glue may result in a prolonged curing time or a weak bond. When using industrial hot melt adhesive, work quickly to avoid the glue cooling too quickly. For large-area bonding, applying in batches can effectively prevent the glue from curing too early.

4. Quick docking and pressure application: After applying the glue, the bonded materials should be docked quickly and appropriate pressure should be applied. This ensures that the industrial hot melt glue is evenly distributed and the bonding effect is the best. For bonding some large objects, it may be necessary to use clamps or other tools to hold the material in place until the hot melt adhesive is fully cured.

5. Cooling and curing: The cooling time of industrial hot melt glue is usually short, but make sure it is fully cured before proceeding. The cooling time is affected by the ambient temperature and the thickness of the glue. In some special cases, hot melt adhesive may need to wait for several minutes to several hours to fully cure.

Dongguan Tingjie – Your edge banding Partner

At Dongguan Tingjie Decoration Materials Co., Ltd., we focus on providing high-quality edge banding and hot melt glue materials for businesses around the world. As a manufacturer in China, we offer competitive prices, bulk order discounts, and customized products tailored to your specifications. Whether you need edge banding for large-scale projects or smaller quantities, we offer wholesale rates and quick delivery times.