In recent years, with the continuous improvement of industrial automation and environmental protection requirements, new adhesives have been increasingly used in various fields. As a bonding material that combines high efficiency, environmental protection and safety, EVA Hot Melt Glue is winning market favor with its unique advantages and becoming a key bonding material in manufacturing, packaging, electronics, automobiles, home decoration and other industries.

This article will deeply analyze the core advantages and prospects of EVA Hot Melt Glue from multiple perspectives to help readers fully understand the technical characteristics and industrial value of EVA Hot Melt Glue.

What is EVA Hot Melt Glue?

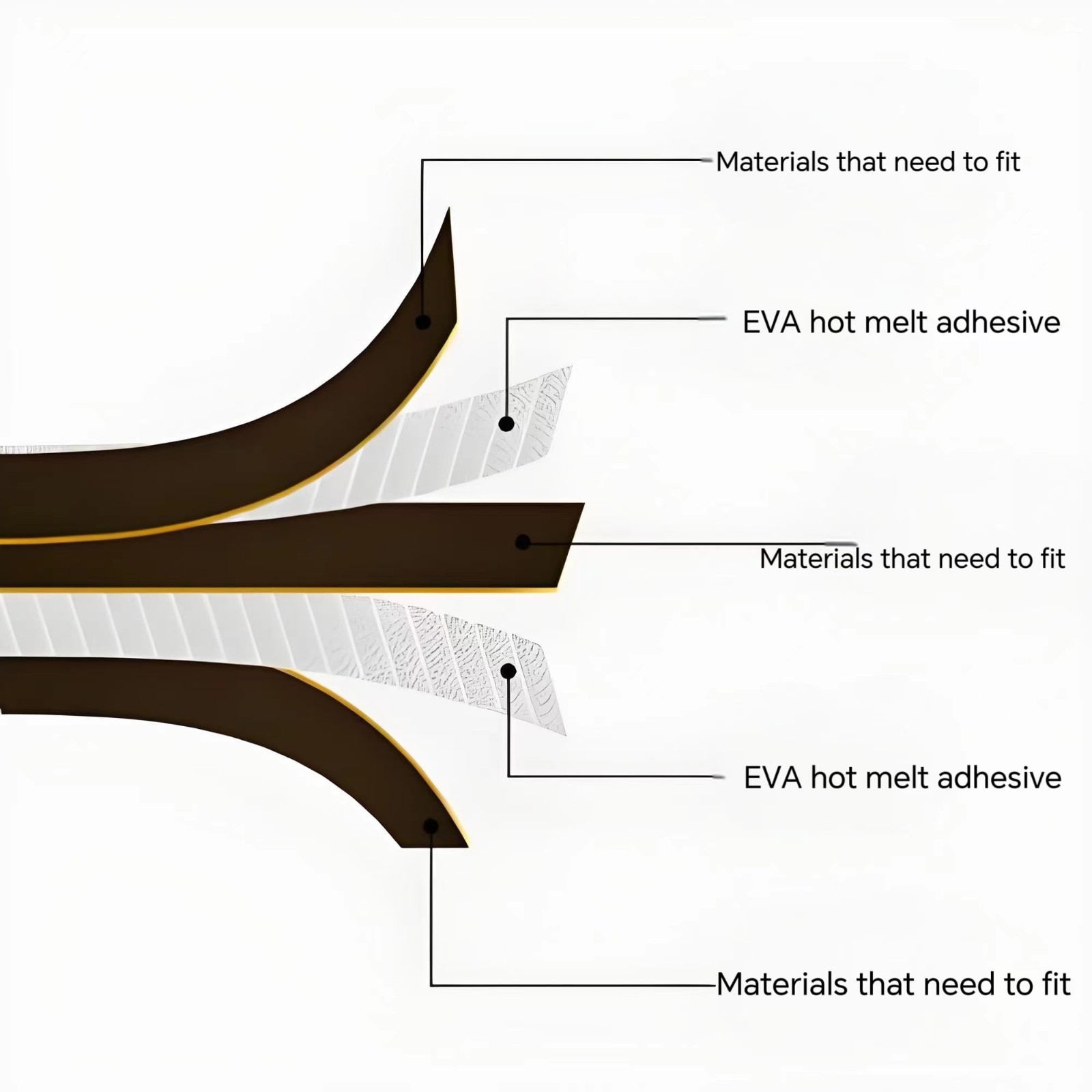

EVA Hot Melt Glue is a thermoplastic adhesive made of ethylene-vinyl acetate copolymer (EVA) as the main ingredient, which is specially formulated and processed by hot melt process. The adhesive melts quickly after heating and solidifies during cooling to form a strong bond. Compared with traditional solvent-based adhesives, EVA Hot Melt Glue does not contain volatile organic solvents. Its processing process relies only on heat energy to achieve the bonding process. This feature not only greatly improves the work efficiency, but also effectively reduces environmental pollution and health risks.

EVA Hot Melt Glue has good fluidity and permeability in the molten state, and can quickly penetrate into the tiny pores of the bonded objects to form a mechanical interlocking structure. Coupled with the synergistic effect of chemical bonding, the bonding effect is more solid. It is based on this principle that EVA Hot Melt Glue is widely used in the bonding of various substrates, such as plastics, metals, wood, textiles, etc. While ensuring the bonding strength, it also meets the special needs of different industries for temperature resistance, weather resistance and chemical resistance.

What are the ingredients of EVA Hot Melt Glue?

The main component of EVA Hot Melt Glue is ethylene-vinyl acetate copolymer, and its ratio and molecular structure determine the basic physical properties of the colloid. In order to meet the diverse needs of bonding performance in different application scenarios, manufacturers usually add plasticizers, antioxidants, UV inhibitors and other functional additives to EVA resin, which not only improves the flexibility and weather resistance of the colloid, but also improves its comprehensive performance such as heat resistance and chemical corrosion resistance. The adjustment of different formulas can make eva hot melt glue maintain excellent bonding effect under different temperature, humidity and load conditions.

What is the manufacturing process of eva hot melt glue?

The production process of eva hot melt glue mainly includes raw material pretreatment, homogenization mixing, granulation, packaging and storage. First, select high-quality EVA resin and various additives, and form a uniform premix through precise weighing and mixing; then melt-mix in the extruder, and make standard granular products after cooling and pelletizing. The final product can be further formulated into hot melt adhesive strips, glue sticks or liquid adhesives with different viscosities and melt indexes according to actual needs. Strict temperature and time control are used throughout the manufacturing process to ensure that the physical properties and chemical properties of each batch of products are stable and reliable.

In addition, in order to meet the needs of automated production lines, modern eva hot melt glue production lines generally use computer control systems to monitor temperature, pressure and mixing uniformity in real time, thereby greatly improving production efficiency and product consistency. This scientific and rigorous manufacturing process allows eva hot melt glue to not only perform well in industrial applications, but also meet the dual standards of environmental protection and safety.

What are the advantages of eva hot melt glue?

The advantages of eva hot melt glue are:

1. Environmental protection and health

2. Rapid curing and efficient production

3. Excellent bonding performance

4. Good heat and weather resistance

5. Diversity and adaptability

6. Energy saving and economic benefits

7. Easy operation and process safety

1. Environmental protection and health: Traditional solvent-based adhesives are often accompanied by the release of volatile organic compounds (VOCs) during use, which not only pollutes the environment, but also may endanger the health of operators. Eva hot melt glue uses a hot melt process, without the use of any organic solvents, eliminating the VOC emission problem from the source. Its non-toxic and harmless properties make it safer and more environmentally friendly during production and use, and meet the strict requirements of modern industry for green production.

2. Fast curing and efficient production: EVA hot melt glue has excellent thermoplastic properties, and can flow and solidify quickly after heating and melting. This rapid solidification process greatly shortens the production cycle and improves production efficiency. On the automated assembly line, EVA hot melt glue can complete the bonding operation within a few seconds, thereby greatly improving the operation speed of the assembly line and the overall production efficiency. For large-scale production enterprises, the fast curing characteristics not only reduce production costs, but also effectively control the processing and transportation time of products.

3. Excellent bonding performance: EVA hot melt glue has excellent fluidity in the molten state, and can quickly penetrate into the microstructure of the substrate to form a stable mechanical interlocking and intermolecular interaction. After cooling and curing, its bonding strength can reach or even exceed the level of traditional adhesives, ensuring the reliability and stability of the product in long-term use. At the same time, EVA Hot Melt Glue has a good bonding effect on a variety of materials (such as plastics, paper, wood, metal, textiles, etc.), making it widely adaptable in diverse applications.

4. Good temperature and weather resistance: EVA Hot Melt Glue is specially formulated to perform well in high temperature resistance, low temperature resistance and weather resistance. Under high temperature conditions, it can maintain a high bonding strength without softening; under low temperature conditions, its flexibility is still maintained, and it will not fail due to brittle cracking. At the same time, by adding anti-ultraviolet and antioxidants, EVA Hot Melt Glue can also maintain stable performance for a long time outdoors and in harsh environments, providing reliable technical guarantees for outdoor advertising, architectural decoration, and the automotive industry.

5. Diversity and adaptability: EVA Hot Melt Glue can be formulated into products with a variety of viscosities, melt indexes, and curing speeds according to different formulas and processes. This flexibility enables EVA Hot Melt Glue to be accurately matched to different application requirements, whether it is the bonding of precision electronic components or the encapsulation of large-area packaging materials, the best solution can be found. Its diverse product forms (such as glue sticks, glue strips, liquid glue, etc.) meet various needs from small batch customization to large-scale automated production, greatly broadening the scope of market application.

6. Energy saving and economic benefits: Due to the rapid curing characteristics of EVA hot melt glue, there is no need to wait for a long time during the production process, which can significantly shorten the process cycle, reduce energy consumption and equipment operating costs. In addition, due to its environmentally friendly and solvent-free characteristics, no additional ventilation facilities or air purification devices are required, thereby reducing the investment of production companies in environmental protection facilities. Overall, EVA hot melt glue not only has advantages in technical performance, but also performs well in energy saving and economic benefits, reducing production costs for enterprises and improving market competitiveness.

7. Easy operation and process safety: The use process of EVA hot melt glue is relatively simple, and the equipment is flexible to operate and easy to maintain. Its melting temperature is usually controlled in a lower range (compared with some high-temperature adhesives), which greatly reduces the operating risk. At the same time, equipment such as hot melt glue guns are humanized in design, with safety functions such as temperature control and anti-scalding, ensuring the personal safety of production personnel during operation. The advantages of easy operation and safety make eva hot melt glue also widely recognized in small and medium-sized enterprises and home DIY applications.

At Dongguan Tingjie Decoration Materials Co., Ltd., we believe in delivering the best value for money. Our company manufactures and supplies PVC, ABS, and eva hot melt glues, offering wholesale prices and discounts for bulk orders. As a professional manufacturer based in Dongguan, China, we ensure top-tier quality and a wide selection of edge banding materials, including T-type and U-type profiles. If you’re looking to purchase high-quality edge banding at low prices, we are here to help. Reach out to us today for custom solutions and competitive quotes.