In furniture manufacturing, cabinet making, architectural decoration and other industries, edge banding is one of the indispensable materials. It not only improves the aesthetics of the board, but also protects the substrate, moisture-proof, wear-resistant and prolongs the service life. Among them, PVC edge banding has always been the mainstream choice in the market due to its high cost-effectiveness, easy processing, rich color and texture selection.

However, with the increasing environmental awareness and the demand for higher performance materials, alternatives to PVC edge banding have gradually attracted attention, among which ABS edge banding has become a popular choice due to its excellent environmental protection characteristics, weather resistance and processing performance.

This article will discuss ABS edge banding as an alternative to PVC edge banding in detail, and make an in-depth comparison of the two in terms of raw materials, performance, processing characteristics, application fields and economy.

PVC and ABS edge banding: Everything you need to know

What is PVC edge banding?

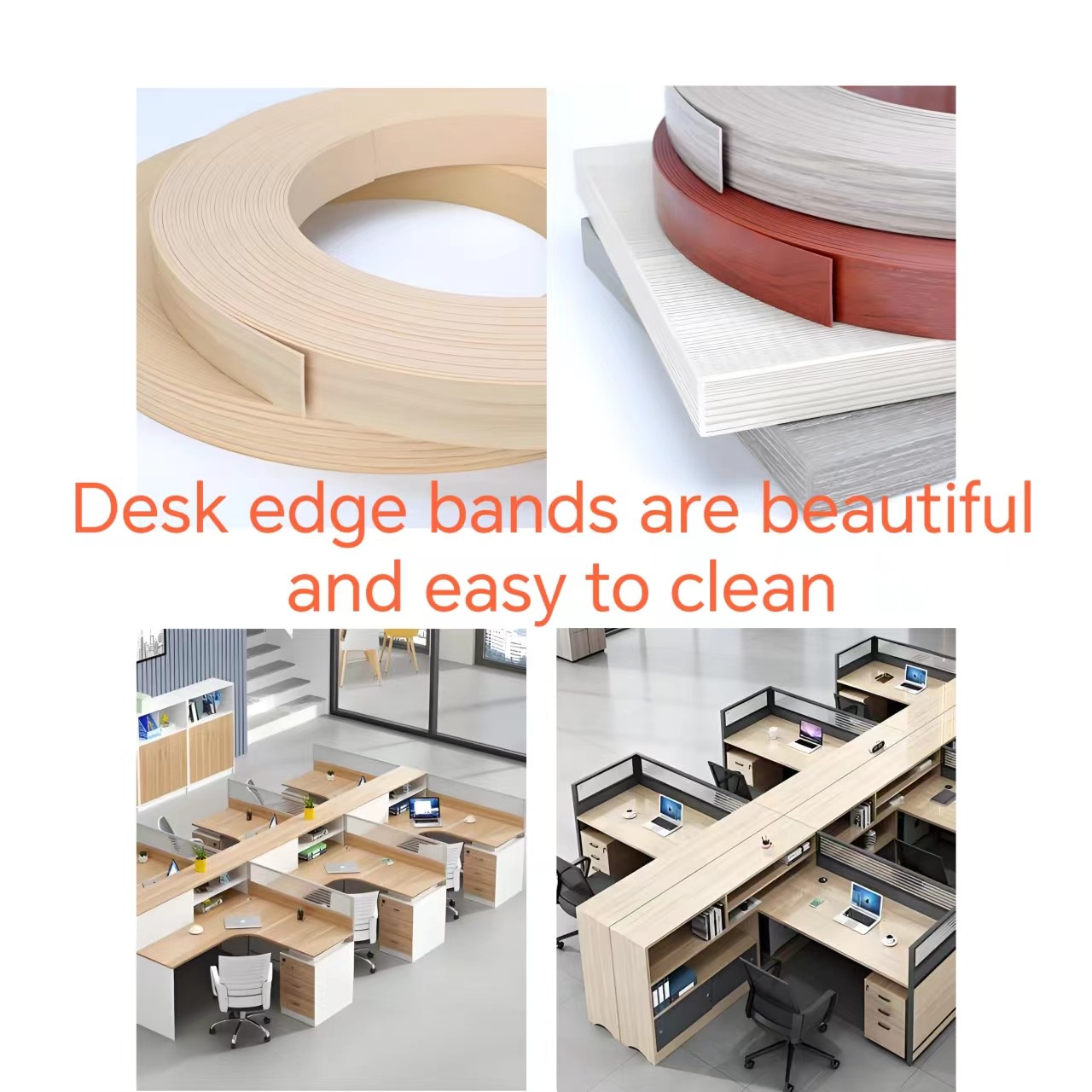

PVC edge banding is an edge banding material made of polyvinyl chloride plastic material, which is widely used to close the edges of wooden products such as furniture, cabinets, doors and windows, and desktops. PVC edge banding not only enhances the appearance of wood products, but also effectively prevents moisture penetration, reduces edge wear, and plays a protective role. Its main features include good durability, moderate cost, and strong impact resistance.

The production process of PVC edge banding usually adopts hot pressing, hot melting or other bonding techniques to ensure good adhesion to wood. Although PVC edge banding has certain advantages, it also faces some environmental issues due to its production process that relies more on chemical components. For example, PVC materials may release harmful gases or pollute the environment during production and use, which affects its performance in terms of sustainability.

What is ABS edge banding?

ABS edge banding is an edge banding material made of acrylonitrile, butadiene and styrene copolymer (i.e. ABS resin). ABS is a synthetic plastic that is widely used in many fields, including the automotive, home appliance and furniture industries, due to its excellent mechanical properties, chemical stability and good processing properties.

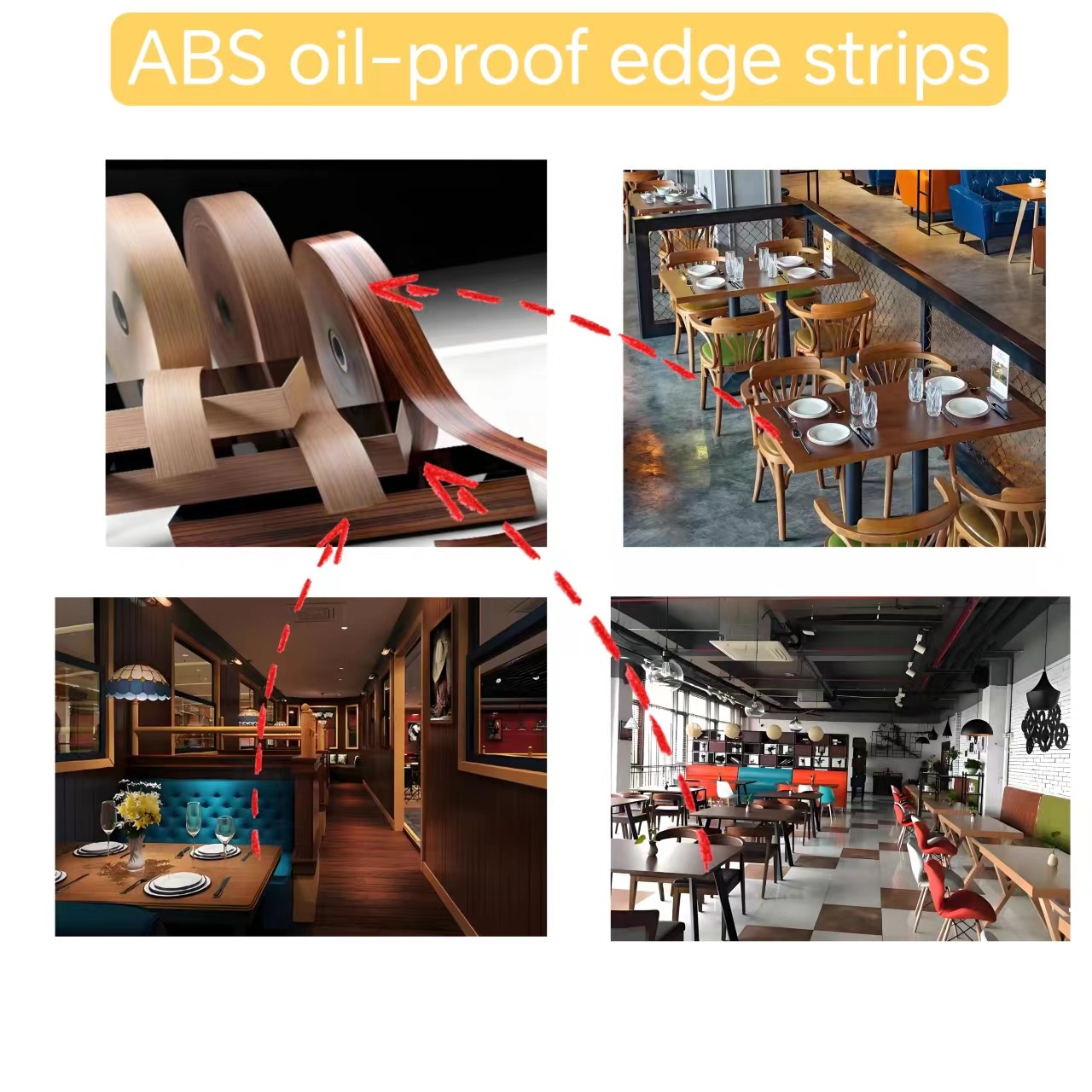

ABS edge banding has certain advantages over PVC edge banding in terms of environmental protection, heat resistance and impact resistance. Since ABS materials do not contain chlorine, no harmful chlorine gas is released during their production process, which meets the requirements of green environmental protection. In addition, the surface of ABS edge banding is smooth and has high scratch resistance. In some applications with high requirements for appearance and quality, ABS edge banding has gradually become an ideal substitute for PVC edge banding.

Why can ABS edge banding replace PVC?

ABS Vs. PVC: Differences in raw materials

● Raw material composition of PVC edge banding: PVC edge banding is mainly composed of polyvinyl chloride (PVC) resin as the main substrate, and plasticizers, stabilizers, fillers, lubricants, pigments and other auxiliary materials are added. In order to improve the flexibility of PVC edge banding, plasticizers are usually added to make it easier to bend and adapt to substrates of different shapes. However, these plasticizers may migrate to the surface over time, affecting the stability of the material and releasing volatile organic compounds (VOCs) in some cases.

● Raw material composition of ABS edge banding: ABS edge banding is copolymerized by acrylonitrile, butadiene and styrene. ABS is a halogen-free, environmentally friendly plastic. Its main advantage is that it does not contain plasticizers, so it does not release harmful substances, and it has excellent mechanical properties and chemical stability. In addition, the surface of ABS edge banding can be treated in various ways, such as embossing, coating and printing, making it comparable to or even more advantageous than PVC edge banding in appearance.

ABS Vs. PVC: Physical and Chemical Properties

Weather Resistance and Durability

● PVC edge banding: Although PVC has good water resistance and chemical corrosion resistance, its weather resistance is poor, especially when it is easily aged under sunlight, which manifests as discoloration, brittle cracking or surface powdering. In addition, the impact resistance of PVC materials is relatively low, and it is easy to become brittle in low temperature environments.

● ABS edge banding: ABS materials are superior to PVC in terms of weather resistance, and their heat resistance and cold resistance are better. Even if they are exposed to ultraviolet rays or high temperature environments for a long time, they are not easy to discolor or age. At the same time, ABS edge banding has strong impact resistance and still maintains good toughness even in low temperature environments, avoiding the impact of brittle cracking on the life of furniture.

Environmental protection and safety

● PVC edge banding: PVC material itself is not environmentally friendly. Chlorides are released during the production process, and it contains chemical additives such as plasticizers. These substances may release harmful substances during use, affecting indoor air quality. In addition, toxic gases such as hydrogen chloride (HCl) may be released during the combustion of PVC, posing a threat to human health and the environment.

● ABS edge banding: ABS edge banding does not contain plasticizers, heavy metals, and halogens, and is a non-toxic and environmentally friendly material. Even under high temperature conditions, ABS materials do not release harmful substances, so ABS edge banding is more popular in countries and markets with strict environmental regulations. In addition, ABS edge banding does not release toxic gases when burning, so it also performs better in fire safety.

Chemical resistance

● PVC edge banding: It has strong corrosion resistance to most common chemicals (such as acid and alkali solutions, detergents, etc.), but some solvents (such as certain alcohols or organic solvents) may affect PVC materials, causing them to deform or dissolve.

● ABS edge banding: ABS also has good chemical resistance and can resist most acid and alkali solutions, but it is more sensitive to strong oxidants (such as concentrated sulfuric acid). However, compared with PVC, ABS is more stable in chemical resistance at high temperatures and is not easy to decompose.

ABS Vs. PVC: Processing performance and applicability

Hot processing performance

● PVC edge banding: The processing temperature range of PVC is narrow, and the temperature needs to be precisely controlled during the processing, otherwise it is easy to cause the material to burn or degrade. In addition, PVC may shrink during hot pressing and edge sealing, affecting the bonding effect.

● ABS edge banding: ABS material has better thermal stability, a wider processing temperature range, and is not easy to produce bubbles or deformation during the edge sealing process. Therefore, ABS edge banding is more adaptable to processing equipment, can meet the requirements of high-speed automatic edge banding machines, and improve production efficiency.

Surface treatment and aesthetics

● PVC edge banding: PVC material surface treatment is relatively easy, and can provide a rich selection of colors and textures through printing, embossing, thermal transfer, etc., and can imitate a variety of decorative effects such as wood grain and metal texture. However, the glossiness of PVC edge banding is relatively low, and it is prone to fading or surface wear after long-term use.

● ABS edge banding: The surface treatment of ABS is also diverse, but because the material itself has a high surface finish and hardness, it performs better in terms of scratch resistance and wear resistance. In addition, the color stability of ABS edge banding is strong, and it is not easy to fade or deform even after long-term use.

ABS Vs. PVC: Economic and cost comparison

● PVC edge banding: Due to the mature production process of PVC and the low cost of raw materials, the price of PVC edge banding in the market is relatively affordable, and it is currently the preferred material for most furniture manufacturers. However, with the continuous upgrading of environmental protection regulations, some regions have increasingly stringent restrictions on the use of PVC, which may affect its economic efficiency in the future.

● ABS edge banding: Compared with PVC edge banding, ABS edge banding has a higher production cost, so the market price is relatively expensive. However, considering its longer service life, stronger weather resistance and environmental protection characteristics, ABS edge banding may have a higher cost-effectiveness in the long-term use process, especially in the market with higher requirements for environmental protection and durability.

ABS vs. PVC: Applicable Fields

● PVC edge banding: Applicable to low-cost, mass-produced furniture, cabinets, desks, door panels, etc., especially for markets with less stringent environmental requirements.

● ABS edge banding: Applicable to high-end furniture, children's furniture, medical furniture, building decoration materials with high environmental requirements, and products exported to the European and American markets, because it meets environmental standards and is safer.

Therefore, from the perspective of environmental protection, weather resistance, processing performance, economy and other aspects, ABS edge banding has many advantages as a substitute for PVC edge banding, especially in the market with increasingly stringent environmental standards. ABS edge banding has become the first choice of more and more high-end furniture manufacturers due to its halogen-free environmental protection characteristics, excellent weather resistance and good processing performance. However, due to cost factors, PVC edge banding still dominates the price-sensitive market.

Dongguan Tingjie – Supplier of Edge Banding Solutions

Dongguan Tingjie is a leading supplier of edge banding materials, offering a wide selection of high-quality PVC Edge Banding, ABS Edge Banding. As a manufacturer based in Dongguan, China, we provide wholesale prices, customized solutions, and discounts on bulk orders to meet the needs of businesses worldwide. Whether you are looking to purchase for large-scale manufacturing or small projects, we offer competitive pricing and efficient delivery services.